Centerless grinder automatic support and centerless grinder automatic loading and unloading method

An automatic bracket and centerless grinding technology, which is applied in the direction of grinding automatic control devices, grinding machines, grinding machine parts, etc., can solve the problems of low production efficiency and high production cost, and achieve improved production efficiency, increased storage space, The effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

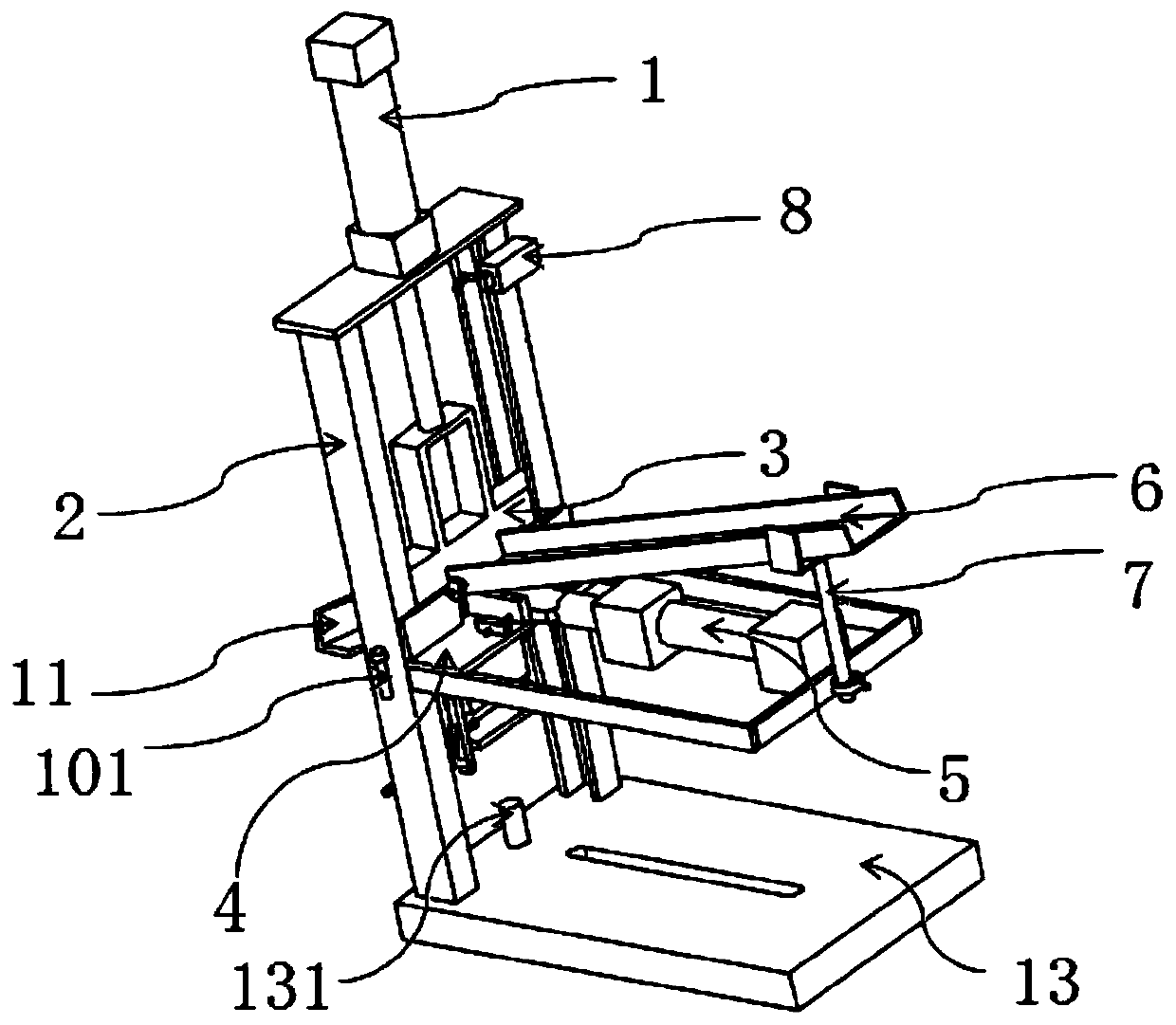

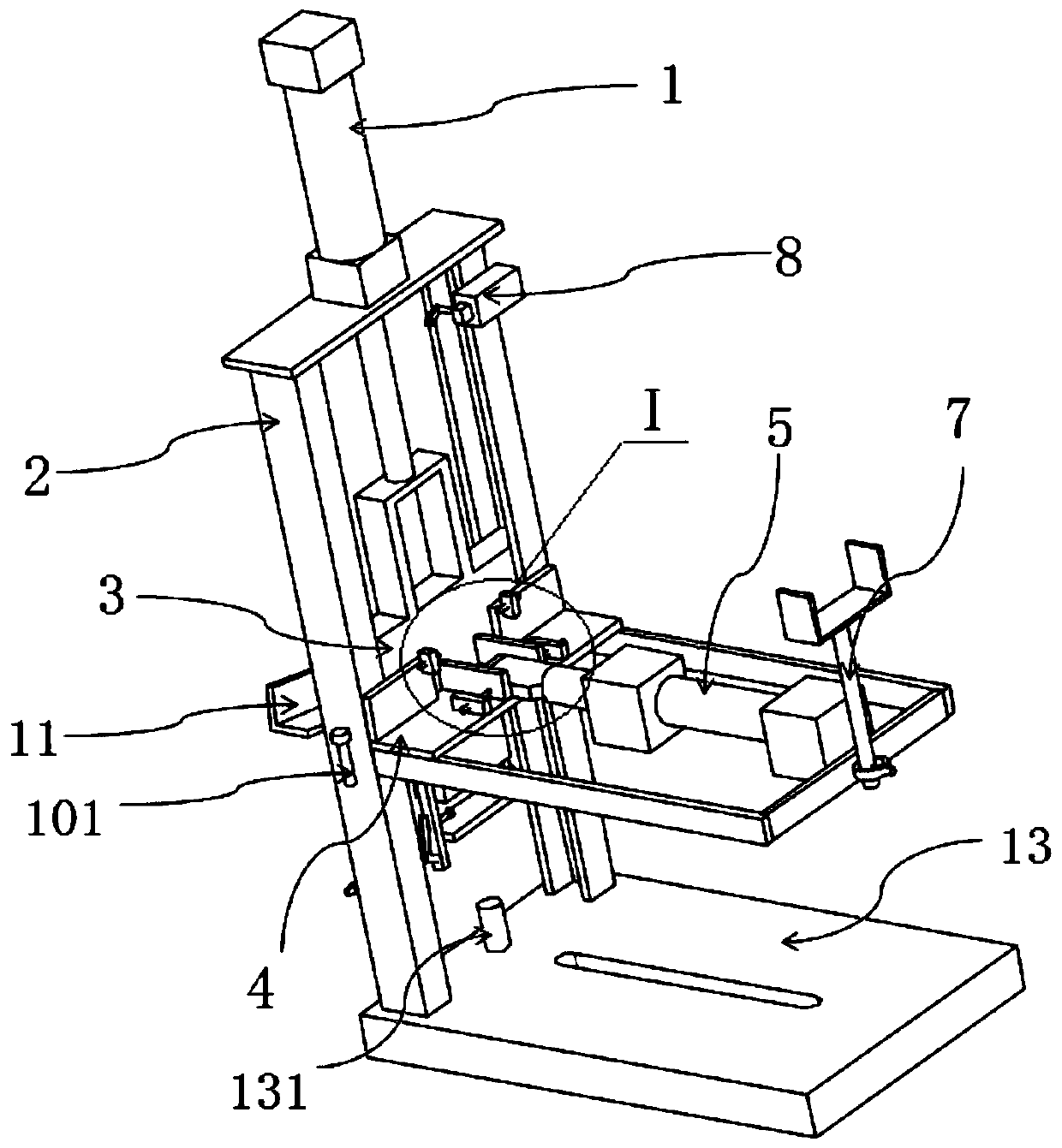

[0042] Such as figure 1 , figure 2 , Figure 4 and Figure 5As shown, an automatic centerless mill bracket includes a vertical drive mechanism 1, a guide module 2, a slide plate 3, a support plate 4, a horizontal drive mechanism 5, a first feed chute 6, a guide trough frame 7, a travel switch 8, The supporting module 9, the spring pressing mechanism 10, the receiving trough 11 and the base 13; the specific structure and relative position of each component are as follows:

[0043] The guide module 2 is made of two chute, which is welded on the base 13 along the vertical direction, so as to cooperate with the grinding machine etc.;

[0044] The slide plate 3 is clamped between the two chute; under the action of the vertical drive mechanism 1, it can move up and down in the vertical direction;

[0045] The support plate 4 is arranged on one side of the guide module 2, that is, the chute, along the horizontal direction, and the second feed chute 401 is arranged on the support...

Embodiment 2

[0055] The difference between the centerless mill automatic bracket of this embodiment and Embodiment 1 is that: the base 13 is also provided with a pallet support adjustment rod 131; the height of the top of the pallet support adjustment rod 131 relative to the base 13 is adjustable, The range is 3-8mm, preferably 5mm.

[0056] The supporting plate support adjustment rod 131 is set on the base 13, which can not only support the supporting plate 901 during the grinding process, but also share the force in the grinding process with the slide plate 3, and prevent the entire support, especially the slide plate, from Shaking is beneficial to ensure the processing accuracy; and after the supporting plate 901 is worn, the tangent point of the grinding wheel and the guide wheel on the composite sheet can be fine-tuned by adjusting the height of the supporting adjusting rod 131, so as to ensure the processing accuracy , improve the service life of the pallet 901.

Embodiment 3

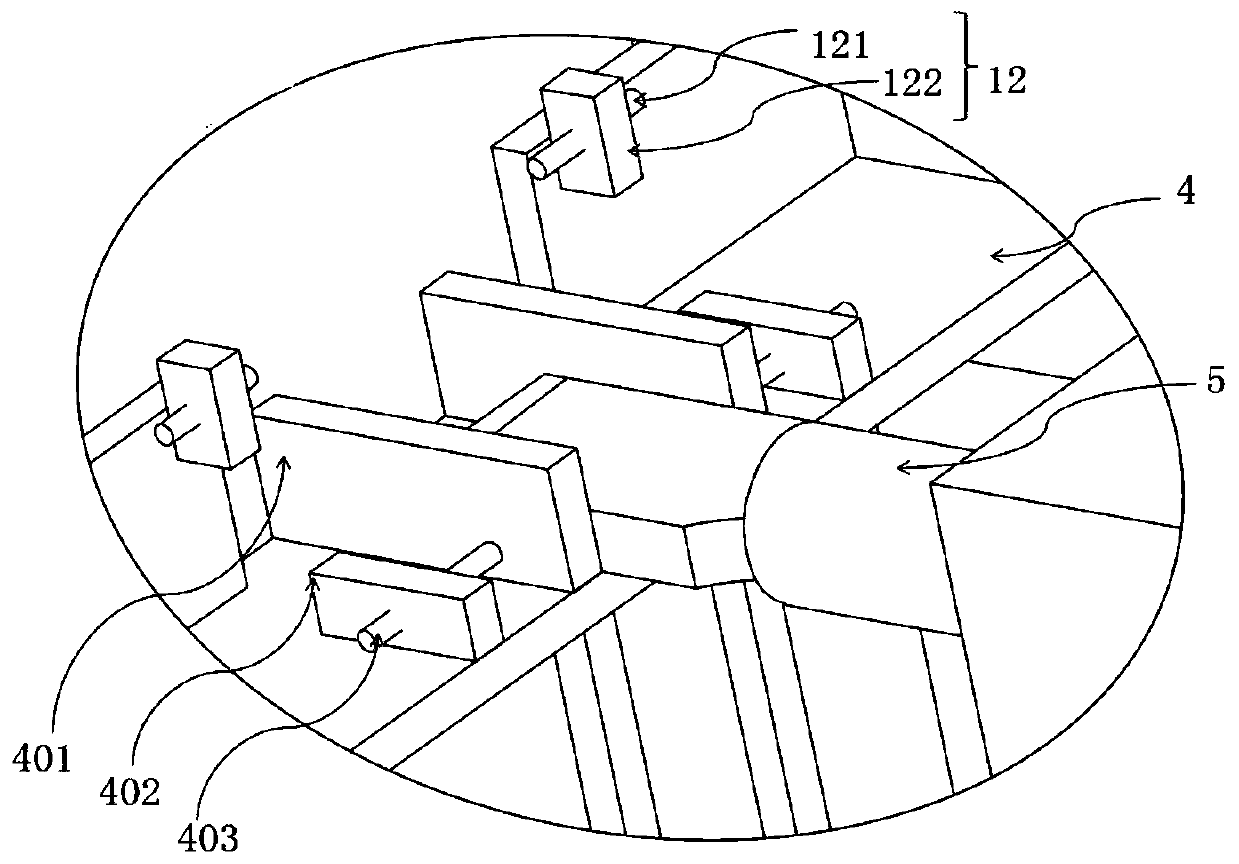

[0058] The difference between the centerless mill automatic bracket of the present embodiment and the embodiment 1 is that it also includes two sets of first feed chute fixing modules 12, such as image 3 As shown, the first feeding tank fixing module 12 includes a second fixing block 121 and a second adjusting bolt 122; the second fixing block 121 is arranged on the outside of the first feeding tank 6, and the second adjusting bolt 122 passes through the second fixing block 121.

[0059] In addition, the support plate 4 is also provided with 2 sets of second feeding chute fixing modules, such as image 3 As shown, the second feeding chute fixing module includes a first fixing block 402 and a first adjusting bolt 403; the first fixing block 402 is fixedly connected on the support plate 4 and is located outside the second feeding chute 401; the first adjusting bolt 403 Pass through the first fixing block 402 .

[0060] The first feeding chute fixing module 12 and the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com