Performing mechanism for smoke exhausting and fireproofing valve and smoke exhausting and fireproofing valve

A technology for actuators and fire dampers, applied in lift valves, valve details, safety valves, etc., to solve problems such as insufficient tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

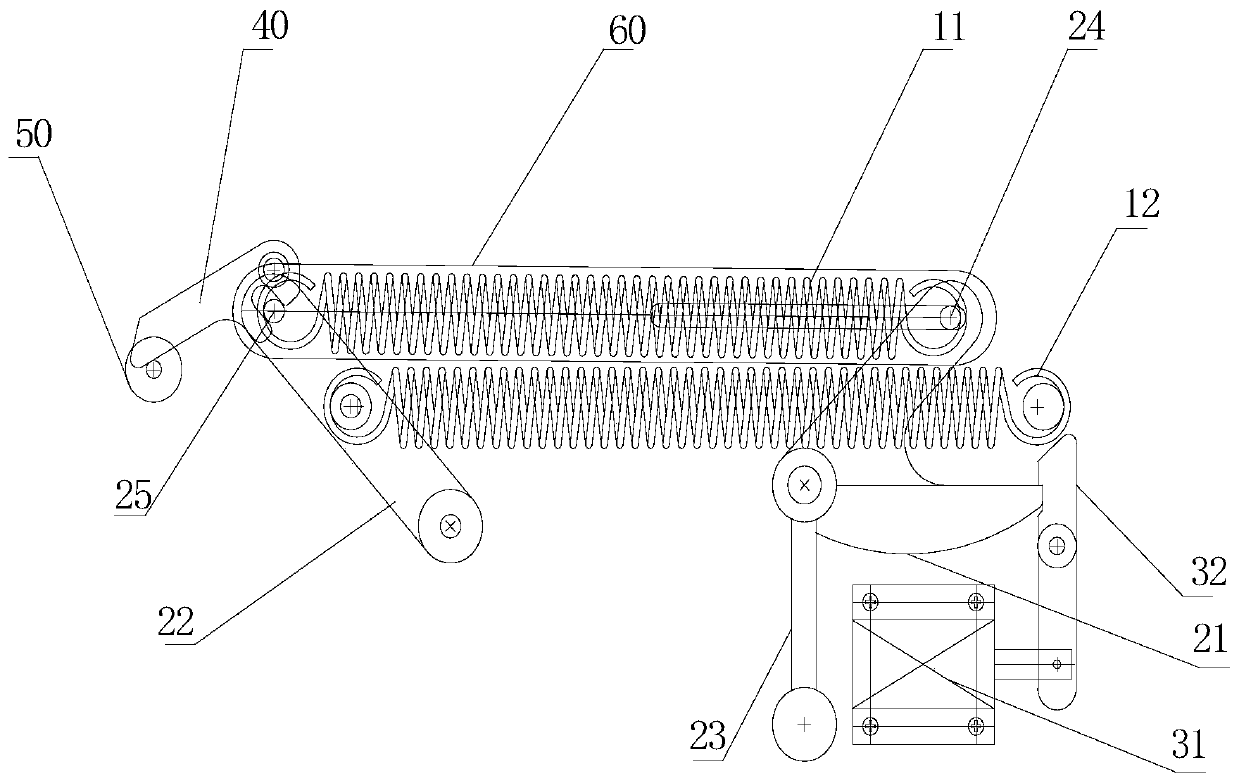

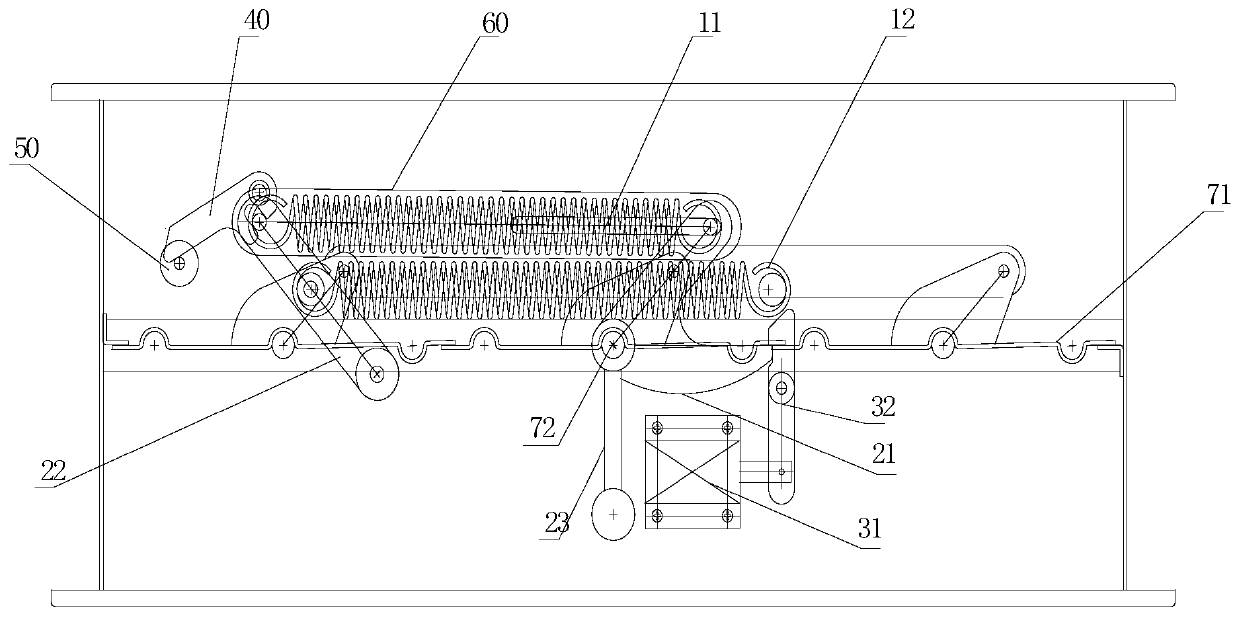

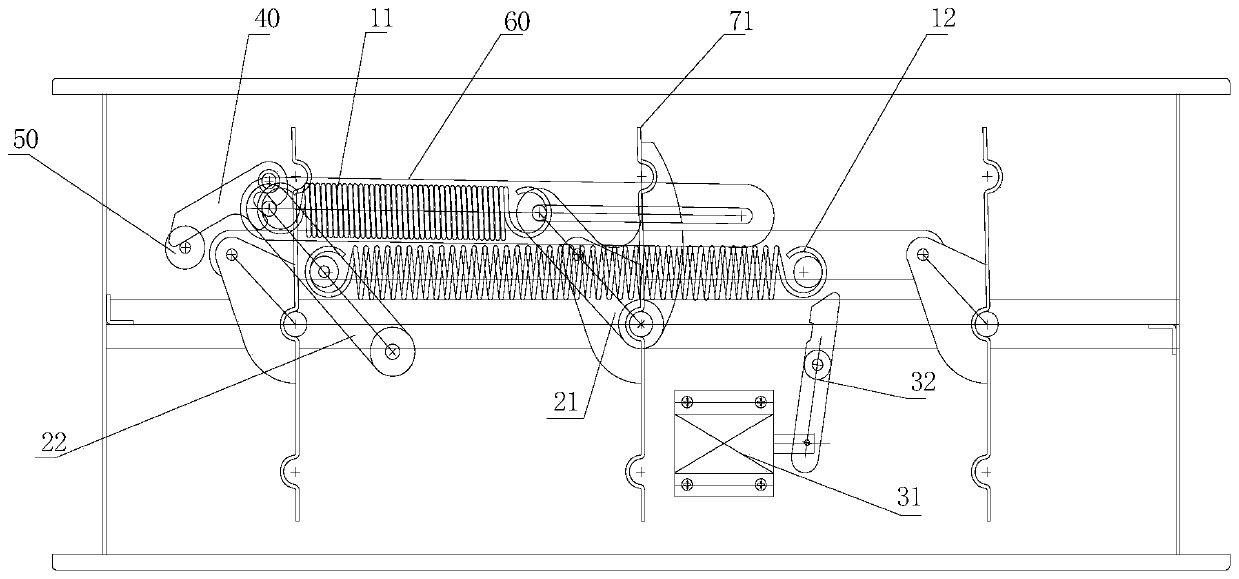

[0047] Such as Figure 1-Figure 4 As shown, the smoke and fire damper actuator provided by the embodiment of the present invention includes: a first elastic member 11, a second elastic member 12, a main shaft rotating rod 21, a secondary rotating rod 22, a limit assembly 30 and a locking arm 40; the main shaft The rotary rod 21 is used to connect with the main shaft 72 of the vane 71 of the valve; the limit assembly 30 can be engaged with or separated from the main shaft rotary rod 21 .

[0048] The auxiliary rotary rod 22 has a first hinge point for hinged with the valve. The first elastic member 11 and the second elastic member 12 have one end hinged with the auxiliary rotary rod 22 respectively. The first elastic member 11 and the second elastic member 12 are located at the second On the same side of a hinge point, and the first elastic member 11 and the second elastic member 12 extend in the same direction; for example, in a specific embodiment, the first elastic member 11...

Embodiment 2

[0072] Embodiment 2 of the present invention provides a smoke fire damper, which includes blades and the smoke fire damper actuator provided in Embodiment 1 above. The main shaft rotary rod in the smoke fire damper actuator is connected to the main shaft of the blade.

[0073] Specifically, as Figure 2-Figure 4As shown, the smoke fire damper includes a housing 73 and a blade 71 installed in the housing 73. The blade 71 is hinged to the housing 73 through a main shaft 72. The main shaft rotary rod 21 in the smoke fire damper actuator and the main shaft of the blade 71 72 to drive the blade 71 to rotate, thereby controlling the opening or closing of the smoke fire damper.

[0074] In the smoke fire damper actuator, the locking arm is hinged to the housing of the valve, one end of the second elastic member is hinged to the auxiliary rotary rod, and the other end is fixed to the housing.

[0075] A plurality of vanes can be installed in the casing, and the plurality of vanes can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap