Communication optical cable and manufacturing equipment

A communication optical cable and manufacturing equipment technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of communication, power, broadcasting interruption, communication optical cable tearing, severe ground drop, etc., to speed up the bonding speed, reduce the impact, and improve the strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

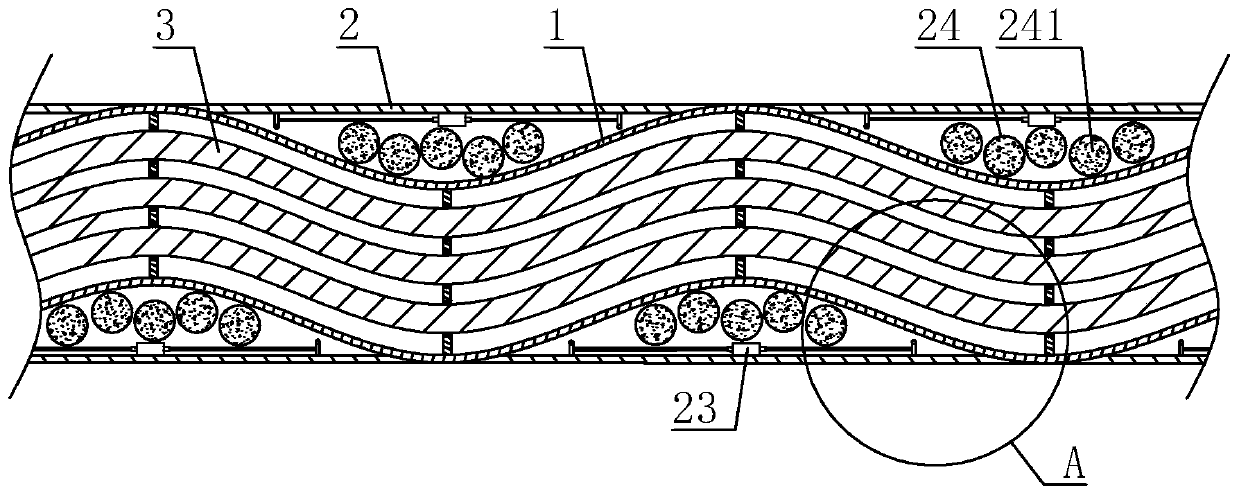

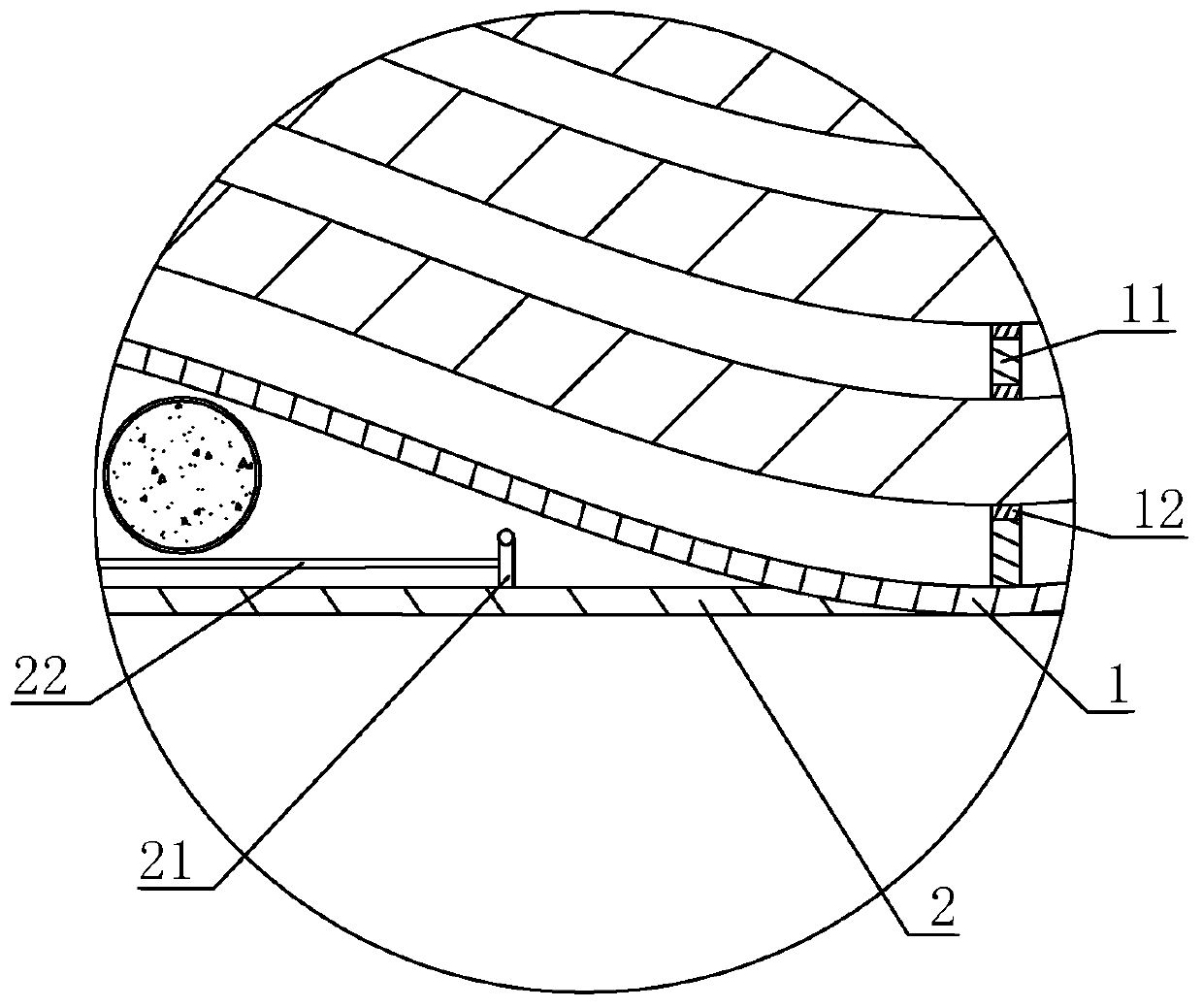

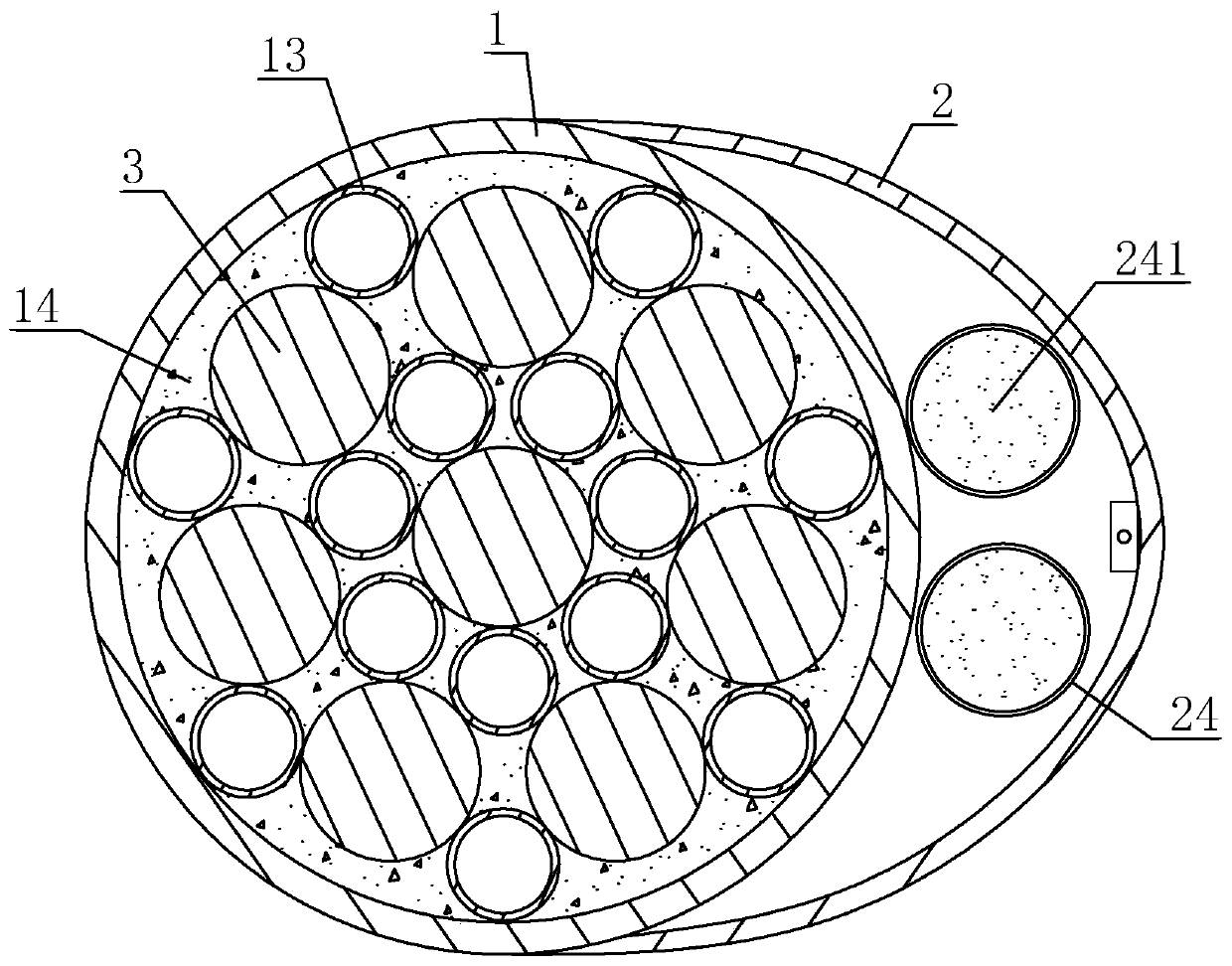

[0044] A communication optical cable, refer to figure 1 , including a protective sheath 1, the protective sheath 1 is arranged in a zigzag manner, and the optical cable body 3 is passed through the protective sheath 1. On the protective cover 1 and between the adjacent peaks, a connecting band 2 is bonded, the connecting band 2 and the protective cover 1 are made of rubber, and a closed cavity is formed between the connecting band 2 and the outer wall of the protective cover 1, And the straightened length of the protective sheath 1 connected with the connecting belt 2 is greater than the limit length of the connecting belt 2, that is, when the protective sheath 1 is straightened, the connecting belt 2 will be broken.

[0045] refer to figure 1 and figure 2 , on the side wall of the connecting belt 2 facing the airtight cavity, two pull rings 21 are fixedly arranged at intervals, and the two pull rings 21 are arranged along the extending direction of the protective cover 1, ...

Embodiment 2

[0052] A kind of manufacturing equipment, is used for manufacturing the communication optical cable in embodiment one, with reference to Figure 4 and Figure 5 , comprising a frame 4, on which two rows of hydraulic cylinders 41 are fixed along the length direction, and the two rows of hydraulic cylinders 41 are arranged in a staggered manner, and the piston rod of each hydraulic cylinder 41 is perpendicular to the length direction of the frame 4. The piston rod of the hydraulic cylinder 41 is connected with an L-shaped bending frame 42, and the short side of the bending frame 42 is fixedly connected with the piston rod of the hydraulic cylinder 41. The long side of the bending frame 42 is horizontal and used to place the first embodiment. The optical cable body 3 in the middle, and the length of the short side of the bending frame 42 is greater than the radius of the optical cable body 3 and smaller than the diameter of the optical cable body 3 .

[0053] During processing, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap