Method for producing and separating lipids

A lipid and separator technology, applied in the production of sophorolipids, the field of equipment for the production, can solve the problems of increasing the viscosity of the medium, reducing the oxygen mass transfer coefficient, and the inhomogeneity of the fermenter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0270] For Example 1, the productivity of the maximum volume is 0.69g L -1 h -1 , for Comparative Example 1C, it was 0.62g L -1 h -1 , showed an 11% increase in effective productivity when separation was used. This is due to the fact that the maximum volume achieved when separation is used is 1540 mL, which is reduced from the maximum volume of 1720 mL without separation. Due to the difference in the feed rate of the fermentation, the corresponding productivity of Example 2 was 0.57 g L -1 h -1 Not directly comparable.

[0271] The use of separation in continuous mode from early in the fermentation made it possible to control the fermentation volume to about 1.3 times the initial volume (whereas without control the fermentation volume would rise to about 1.7 times the initial volume after 280 h). This can equate to an effective productivity increase of over 30%.

[0272] In Example 2, the sophorolipid was extracted for the first time at 71.5 hours, at this time, it was ...

Embodiment 3

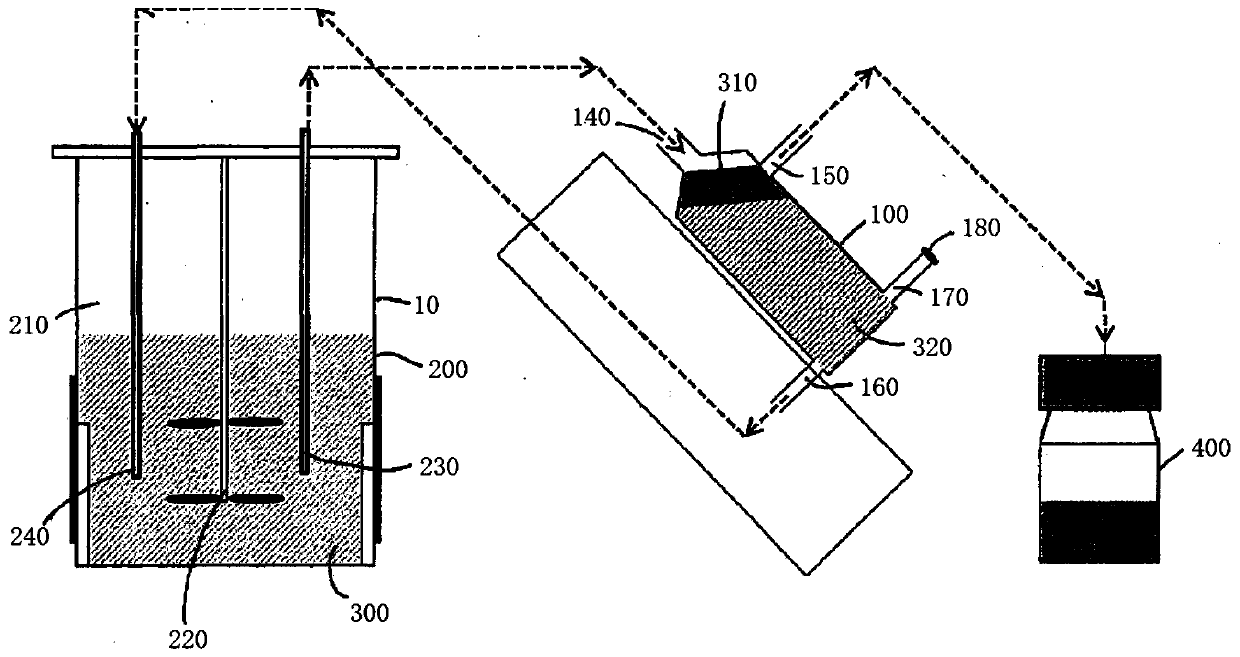

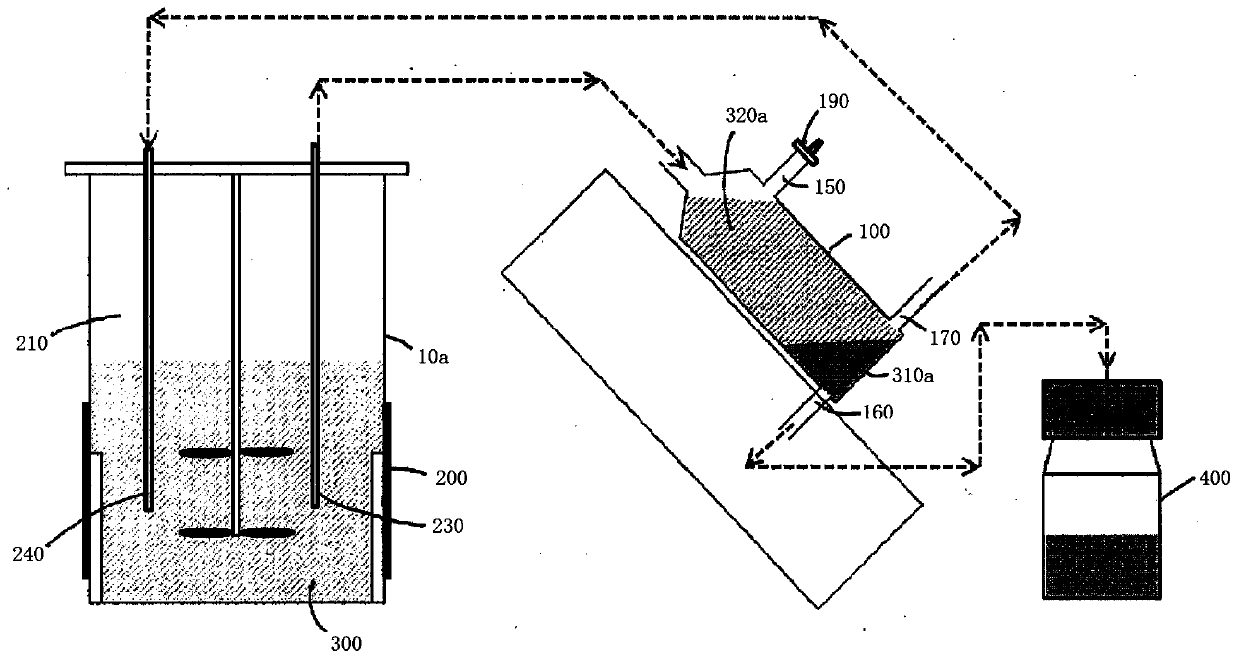

[0277] Example 3 uses an alternative separator and fermentation conditions. The separator used is Figure 7 Built-in settling column shown in .

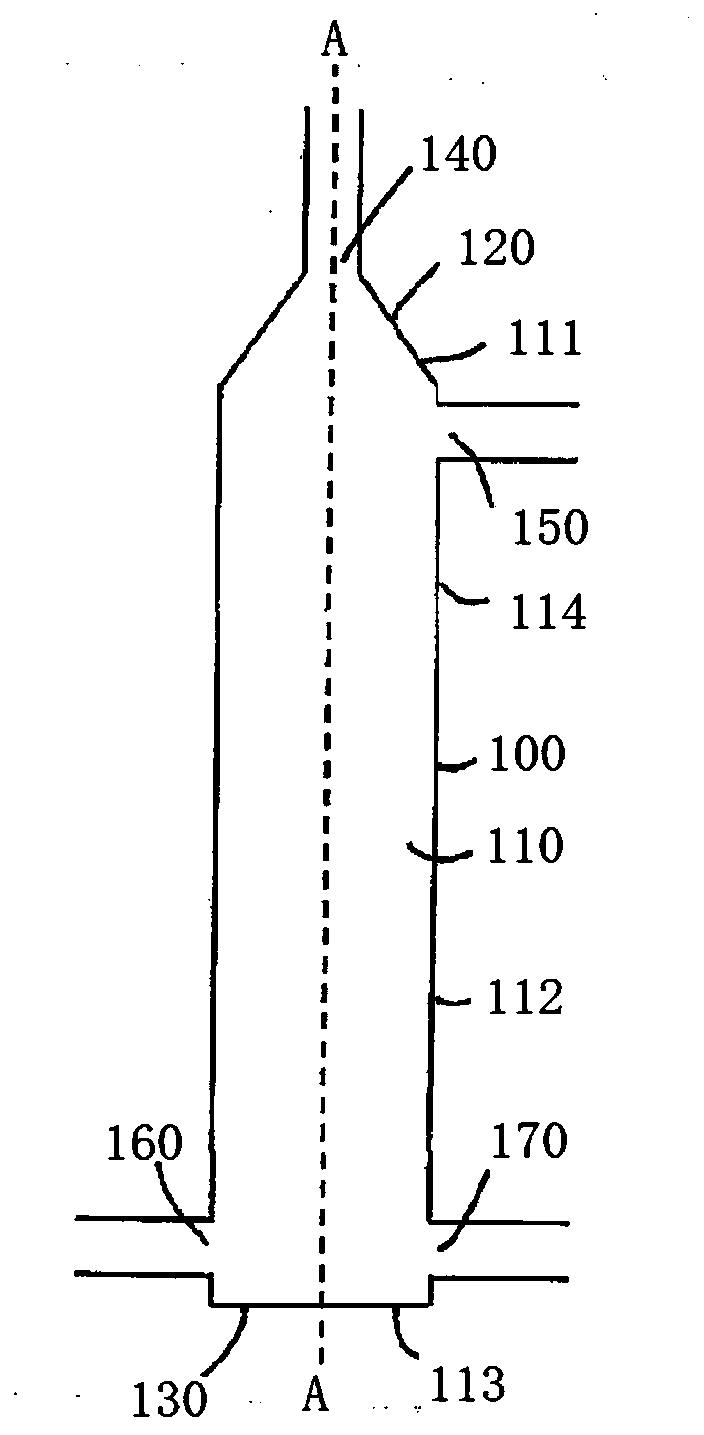

[0278] Separator 1100 includes a separation chamber 1110 . In use, at the first lower end 1120 of the separator 1100, the separation chamber 1110 has a frustoconical portion 1111. The separation chamber 1110 also includes a cylindrical portion 1112 having a diameter of 50 mm and a length of 150 mm. In use, the bottom 1113 of the cylindrical portion forms the in-use upper end 1130 of the separator.

[0279] The separator 1100 includes a culture fluid inlet 1140 and has an opening to the separation chamber 1110 at the first end 1120 of the separation chamber 1110 and on the longitudinal axis A-A of the separation chamber 1110 . The inlet receives the broth 300 containing the lipid product from the fermenter 200 .

[0280] Separators include as Figure 7 The first exit (IIIA) shown in 1160 and Figure 7 The second exit (IIIB) sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com