A device and method for fabricating fiber gratings with arbitrary patterns

A technology for fiber grating and preparation device, which is applied in the directions of cladding fiber, optical waveguide light guide, etc., can solve the problem of limited fiber grating, achieve easy realization, realize fiber grating writing of any pattern, light source coherence and mechanical stability of the device low bottom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

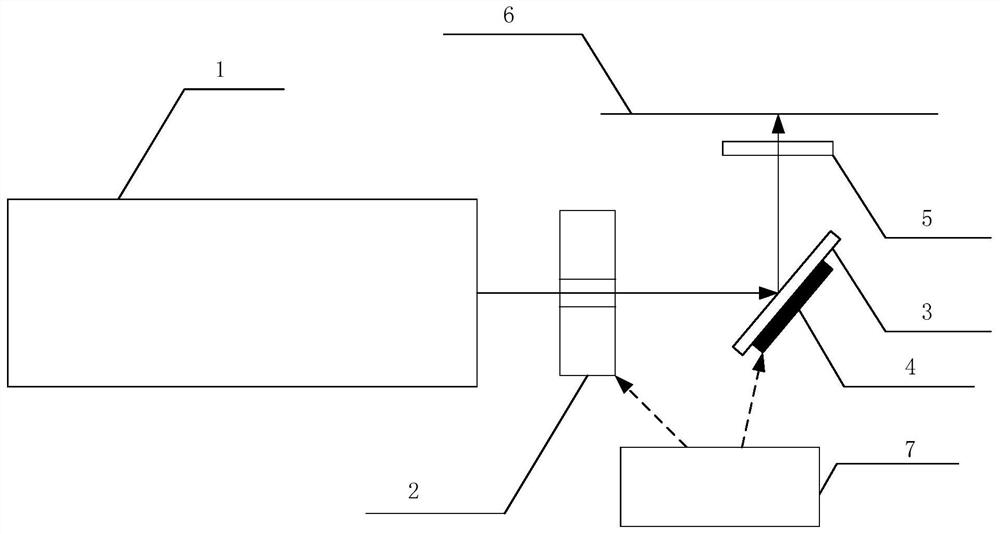

[0025] Embodiment: A fiber grating preparation device with any pattern, including a writing light source 1, a controllable aperture 2, a mirror 3, a phase mask 5, and a grating to be written 6; the writing light source 1 is an ultraviolet continuous writing laser, and the writing light source 1 is used to provide fiber grating writing light, the writing light source 1 can be a 244nm frequency doubled argon ion laser, the fiber grating writing light passes through the controllable diaphragm 2 controls the passage and closing of the fiber grating writing light, the fiber grating writing light passes through the controllable light The optical fiber grating writing light that passes through the controllable aperture 2 is emitted by the diaphragm 2, and is incident on the phase mask 5 by the reflection of the mirror 3. The phase mask 5 is a uniform phase mask used for writing Bragg gratings. The plate 5 and the reflector 3 are placed on the movable support 4, and the movable support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com