Robot welding visual sensor for weld joint and molten bath monocular two-position image synchronous acquisition

A visual sensor and robot welding technology, applied in manipulators, program control manipulators, manufacturing tools, etc., can solve the problem of not being able to realize robot seam tracking and molten pool monitoring at the same time, clearly obtain laser stripe images and molten pool images, and flexibility Large and other problems, to achieve the effect of saving processing time and labor costs, good stability and imaging quality, and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

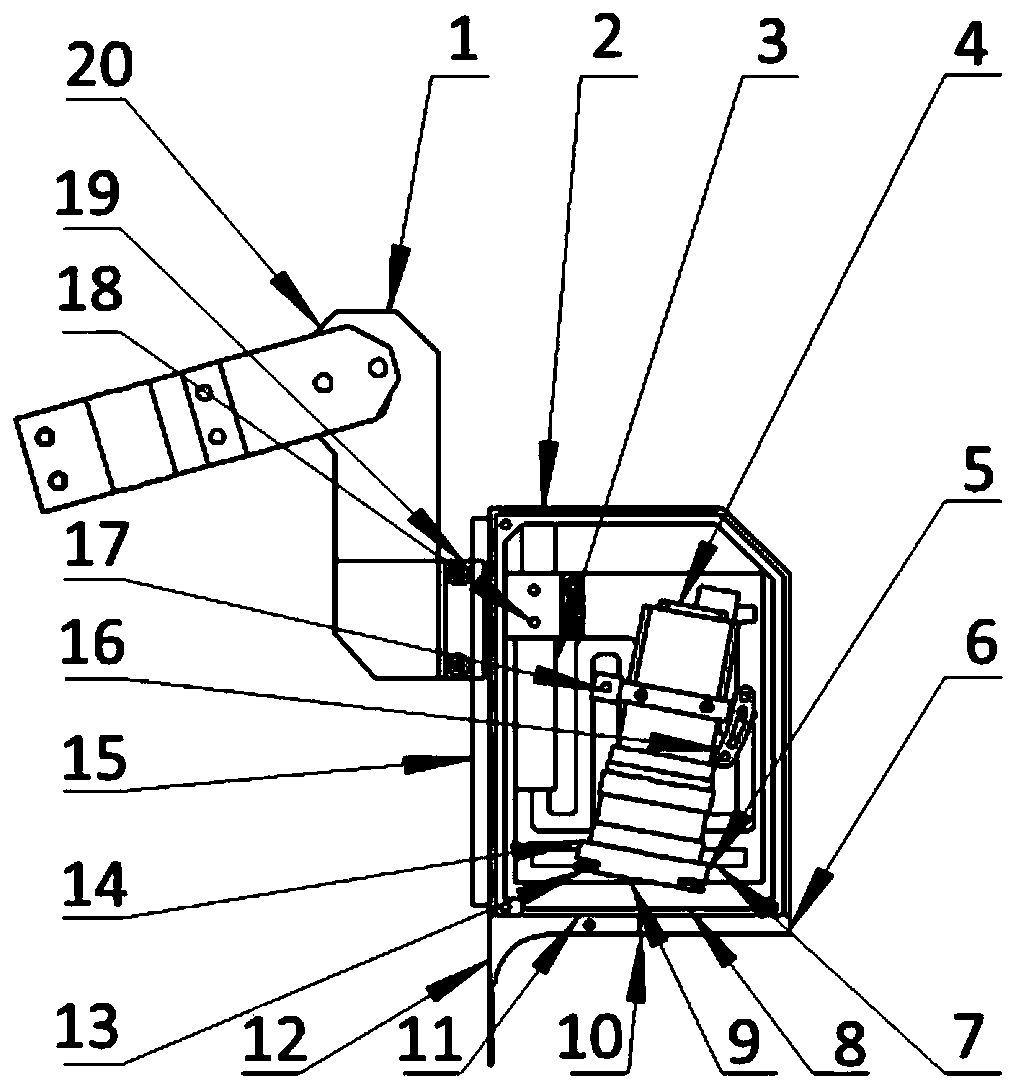

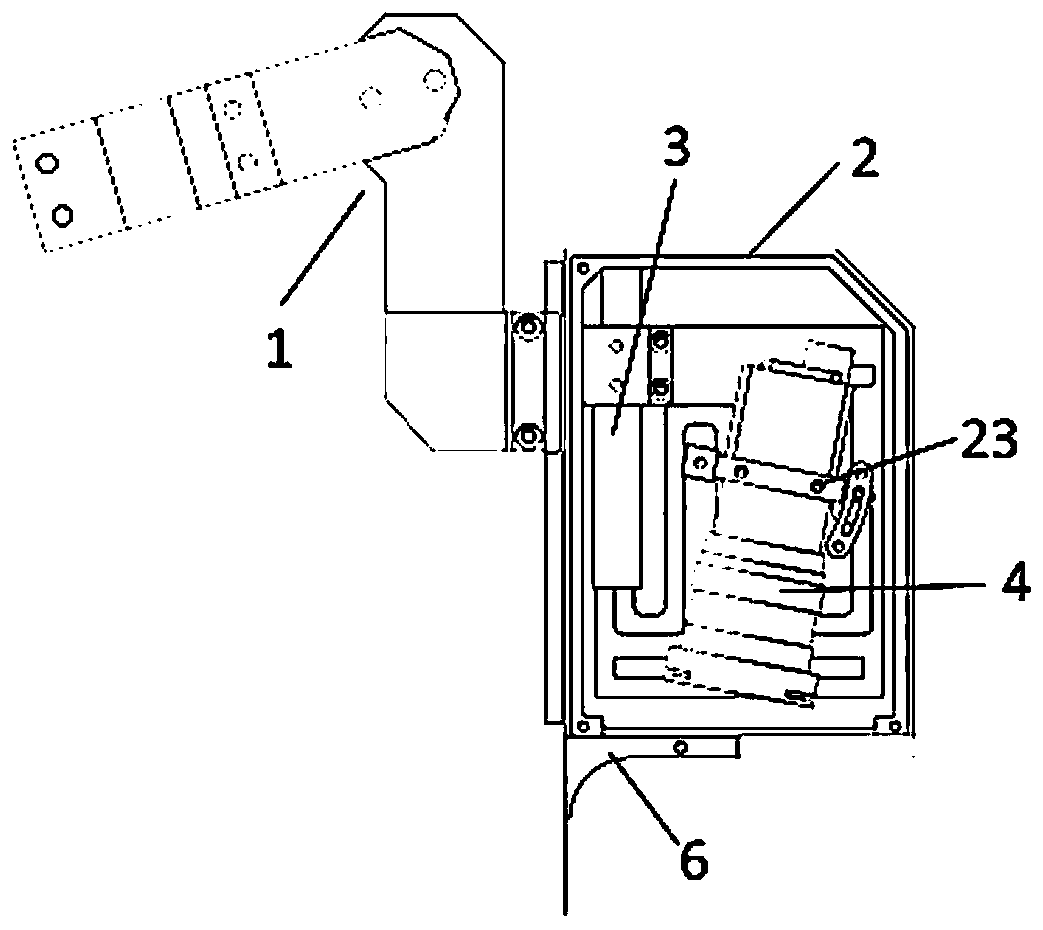

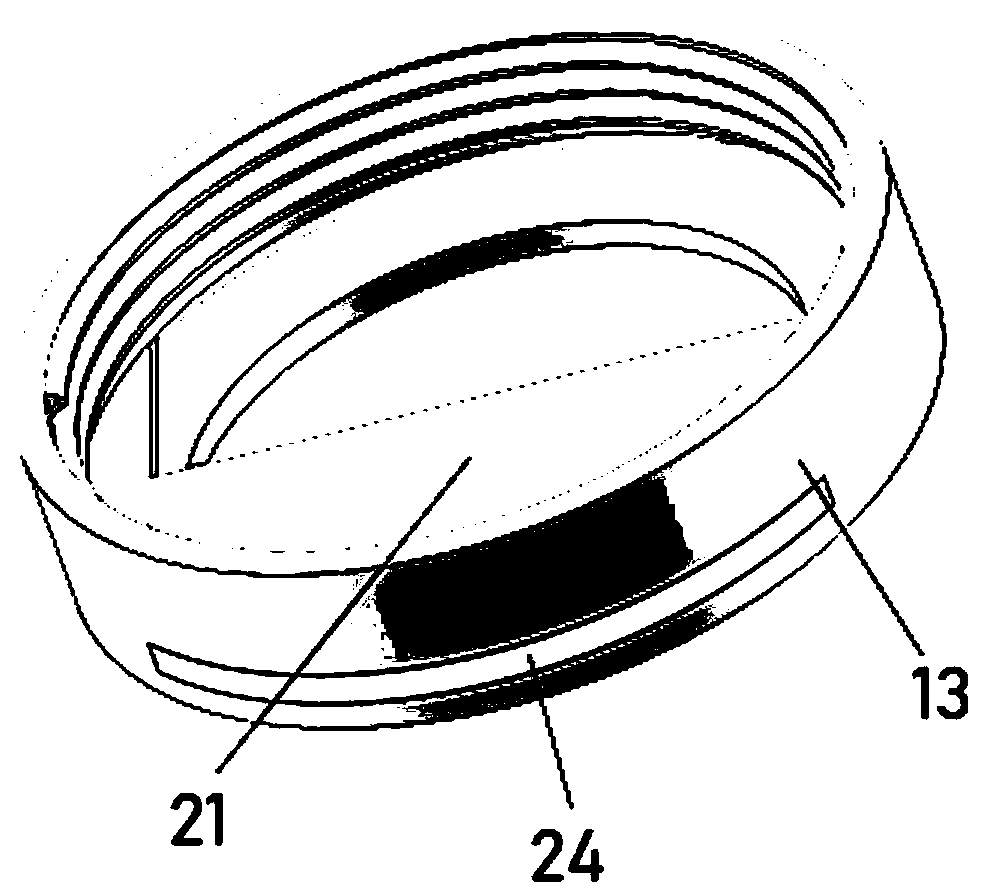

[0024] Such as figure 1 with figure 2 As shown, it is a robot welding vision sensor involved in this embodiment, which includes: a mounting bracket 1, a system housing 2, a laser 3, a camera 4, a light reduction filter system 5, a protection mechanism 6 and a heat dissipation mechanism 7, wherein: The mounting bracket 1, the system shell 2, and the brackets in the light reduction filter system 5 are all made by nylon 3D printing method. The system shell 2 is fixed on the sixth axis of the robot through the mounting bracket 1, and the laser 3 is fixed through the mounting bracket 1. On the inner wall of the system shell 2, the camera 4 is rotated and installed on the inner wall of the system shell 2 at an inclination angle of 10-25°, the welding image captured by the camera 4 is transmitted to the industrial computer through the interface, and the light reduction filter system 5 is set on the side of the camera 4 The front end is fixed on the surface of the lens to change the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com