Self-sealing layered CNT paper/SiC gradient nanocomposite material and preparation method thereof

A technology of nano-composite materials and multi-layer composite materials, which is applied in the field of nano-composite materials, can solve problems such as the reduction of electrical and thermal conductivity, and achieve the effect of improving flexibility and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

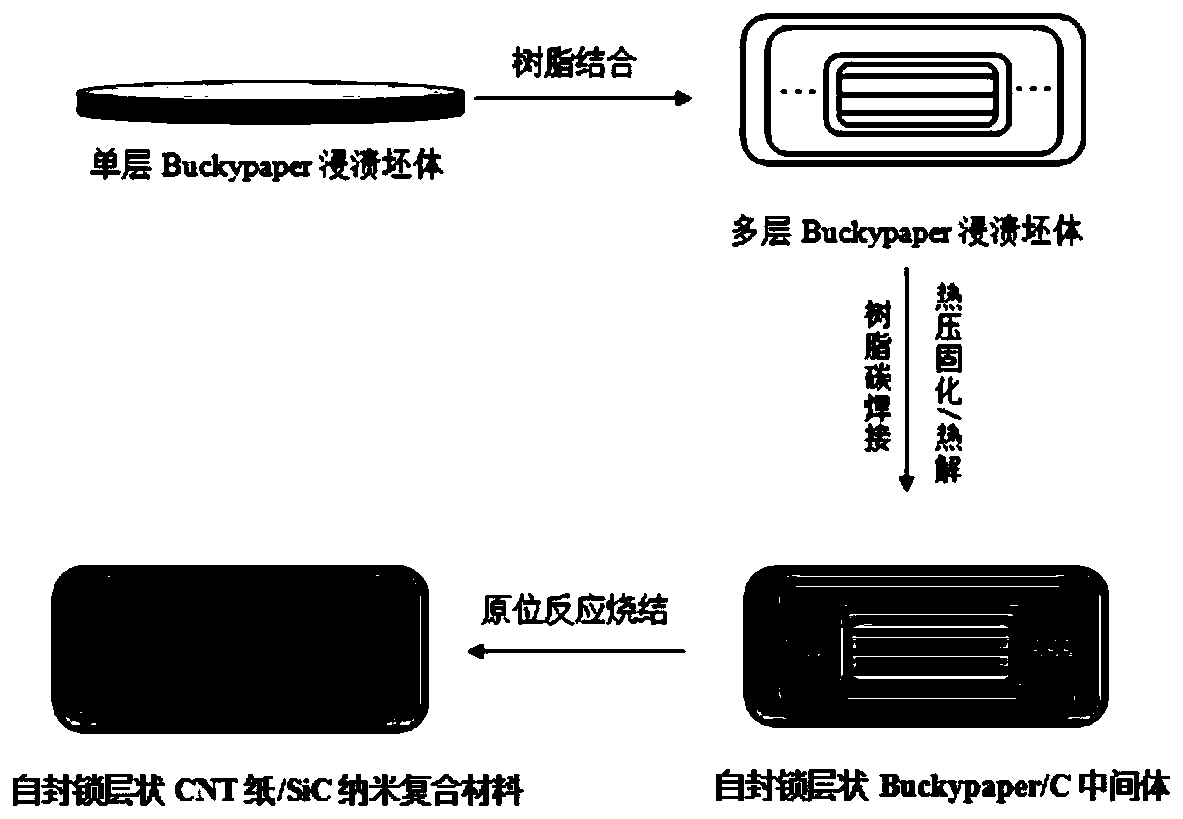

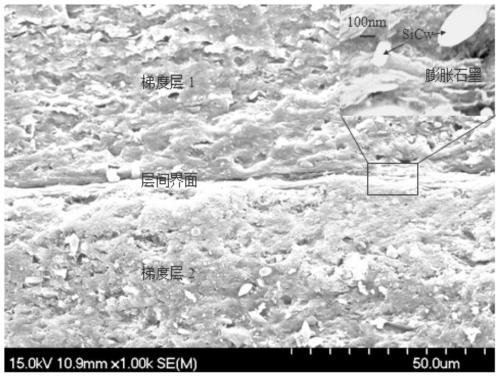

[0065] The preparation method of the CNT paper reinforced SiC-based gradient nanocomposite of the present invention specifically comprises the following steps:

[0066] 1. Preparation of CNT Buckypaper preforms with different layers

[0067] CNTs, B 4 The mass ratio of C micropowder and Si powder is (1~2):(0.5~1.5):(0~1.6). For different layers of Buckypaper preforms, CNTs and B 4 The content of C gradually increases the content of Si powder. The preparation method of single-layer CNT Buckypaper preform is the same as that of patent ZL201410475361.1.

[0068] 2. Impregnated with phenolic resin

[0069] Mix expanded graphite and Si powder at a ratio of (3-5):(1-2), and introduce a very small amount of nano-iron powder, and disperse through ultrasonic waves. The dispersion medium is absolute ethanol, and a uniformly dispersed suspension is obtained. After drying, the expanded graphite mixed powder is obtained.

[0070] Thermoplastic phenolic resin, expanded graphite mixed po...

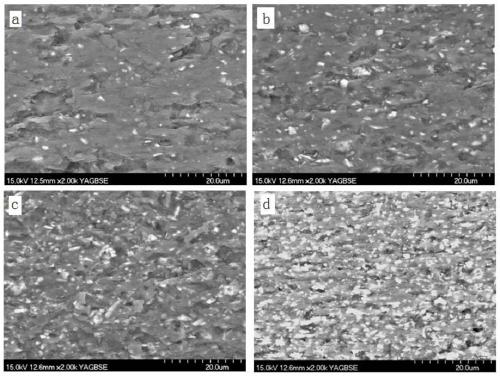

Embodiment 1

[0095] 1) 1g CNTs and 0.8g B 4 C micropowder is dispersed in 1000ml distilled water, drop into 0.9ml surfactant Triton TM X-100, disperse by pulse ultrasonic for 60min to obtain a dispersed, uniform and stable suspension; among them, the diameter of CNTs is about 10-20nm, the length is >30μm, and the density is 2.10g / cm 3 ;B 4 The particle size of C micropowder is 0.05~5 μm, and the density is 2.52g / cm 3 ; The particle size of Si powder is 0.1-1.5μm, and the density is 2.34g / cm 3 . In addition, the period of pulsed ultrasound is 1min, and the interval of every 30s of ultrasound is 30s, the frequency of ultrasonic vibration is 20kHz, and the power is 1300W.

[0096] 2) Prepared by the pressurized filtration method in the patent ZL201410475361.1 contains B 4 CNT Buckypaper preforms of C powder and Si powder.

[0097] 3) Using 1) and 2) steps to prepare CNTs 1g, B 4 C 0.8g, two CNT Buckypaper preforms of 8 formulations with elemental Si respectively 0.1g, 0.2g, 0.3g, 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com