A side pre-embedded installation method of C-type Hafen groove for concrete structure

A technology of concrete structure and installation method, which is applied to underwater structures, foundation structure engineering, building construction, etc., can solve the problems of weakening the mechanical performance of the Hafen trough, reducing the service life of the formwork, and affecting the installation quality of the bracket, etc., to achieve The effect of improved installation quality and appearance quality, no rework, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

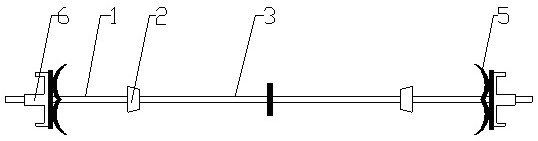

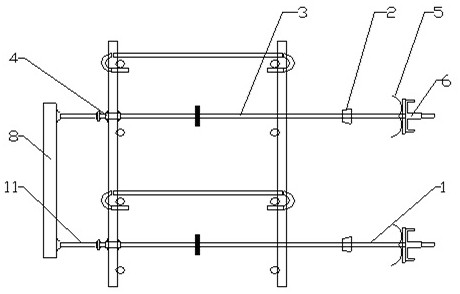

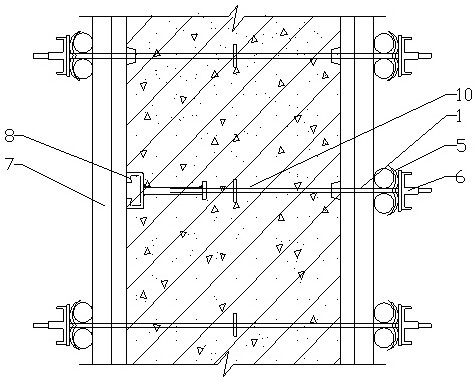

[0021] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 4 As shown, the lateral pre-embedded installation method of C-type Hafen groove for concrete structure includes the following steps:

[0022] The first stage: According to the thickness of the concrete wall, three-stage water-stop screws with different lengths and different diameters are ordered, and the turnover screw 1 and plastic plug 2 at one end of the three-stage water-stop screw are removed to form a half-stage water-stop Screw rod 9 is for subsequent use; Three-section type water-stop screw rod is prior art, can all be bought on the market, just needs to make different lengths and diameters, as figure 1 As shown, it consists of revolving screw 1+plastic plug 2+waterproof inner support 3+plastic plug 2+revolving screw 1. Revolving screw 1 is matched with butterfly buckle 5 and fastening bolt 6. The middle waterproof pair The inner support 3 is used to control t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap