Pressing type throttling ball valve

A throttling ball and pressing technology, applied in the field of control valves, can solve the problems of wear of the sealing ring, water saving, and the ball valve cannot achieve throttling, etc., and achieve the effect of prolonging the use time, reducing damage and loss, and reducing friction and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

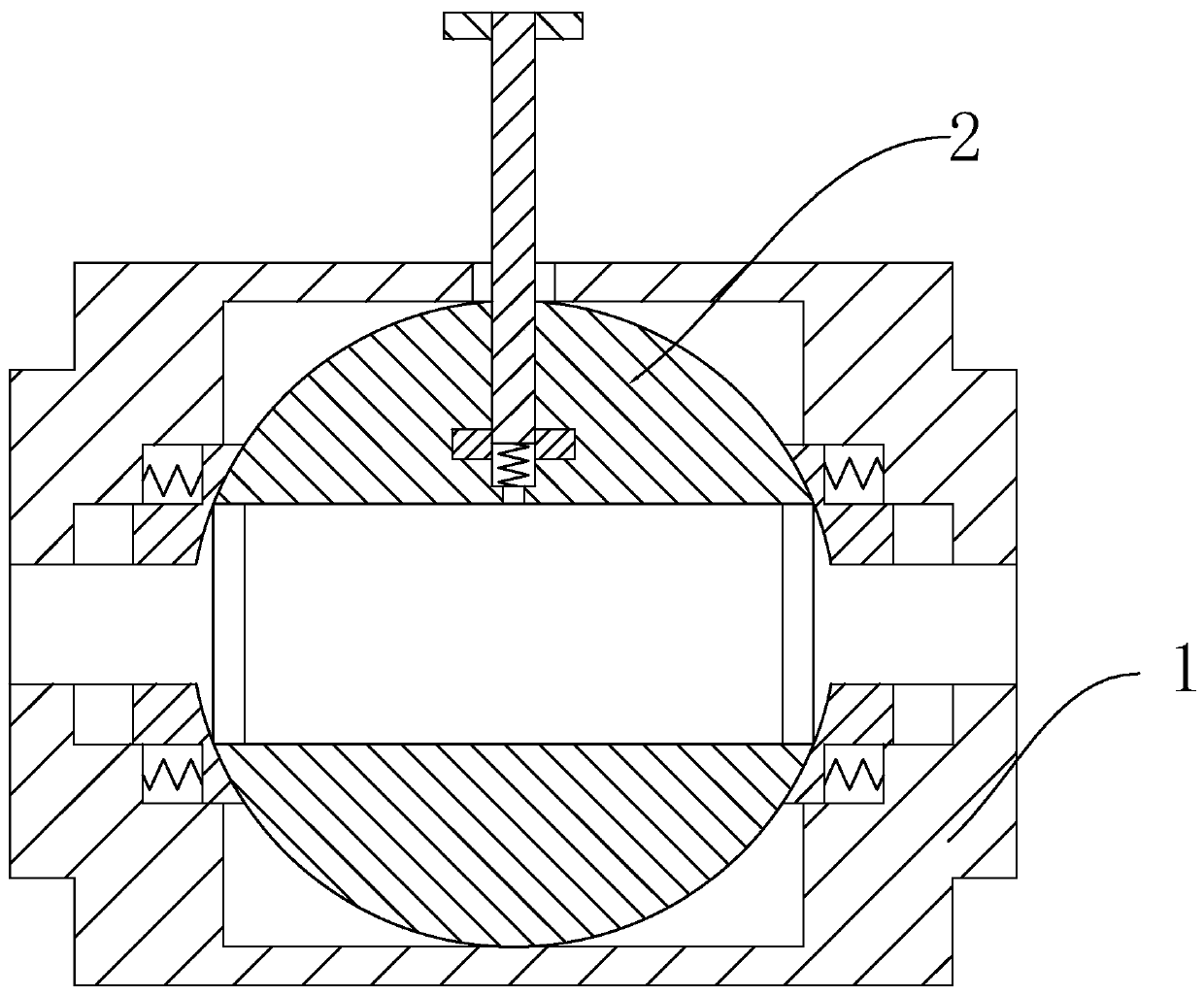

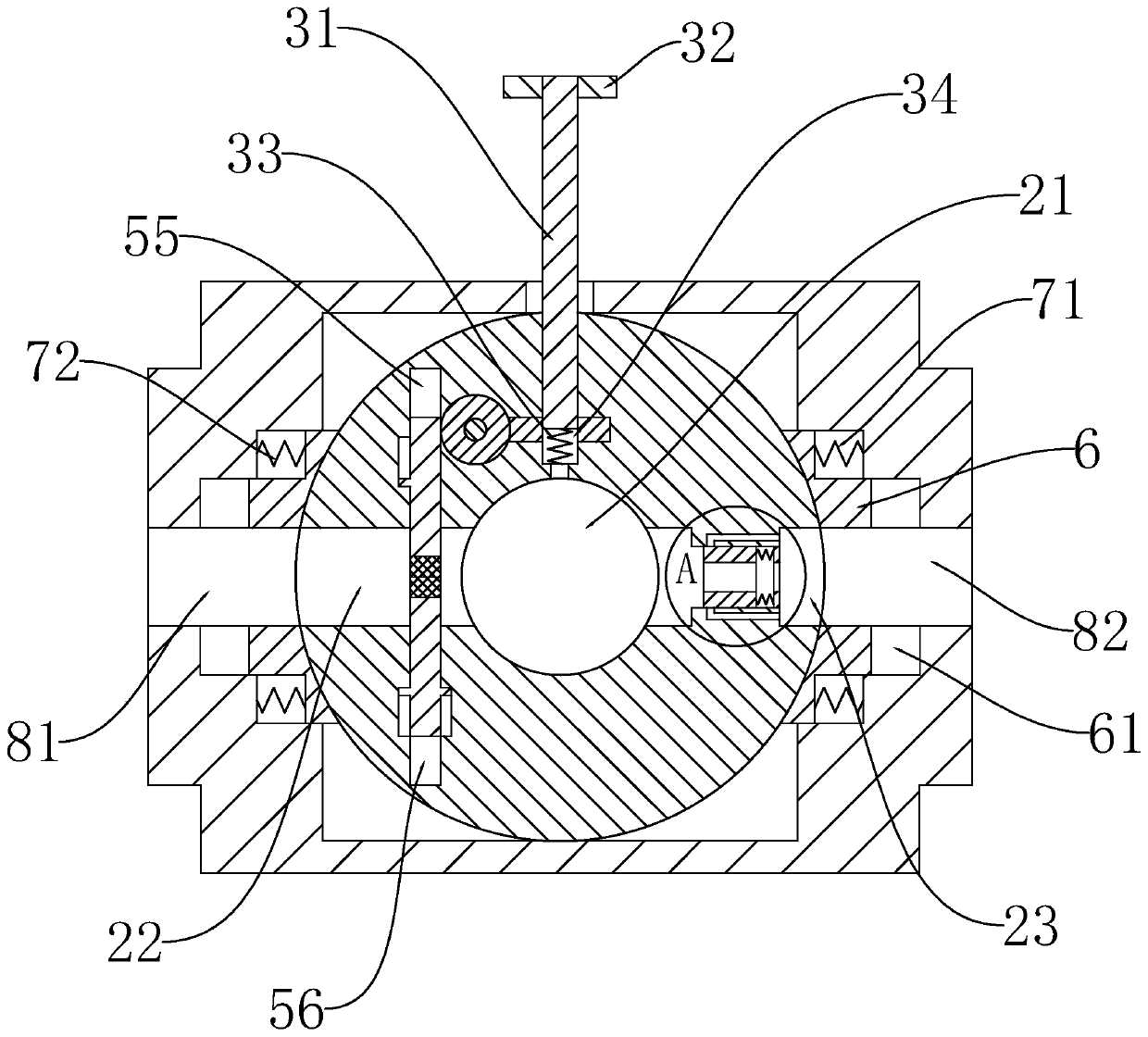

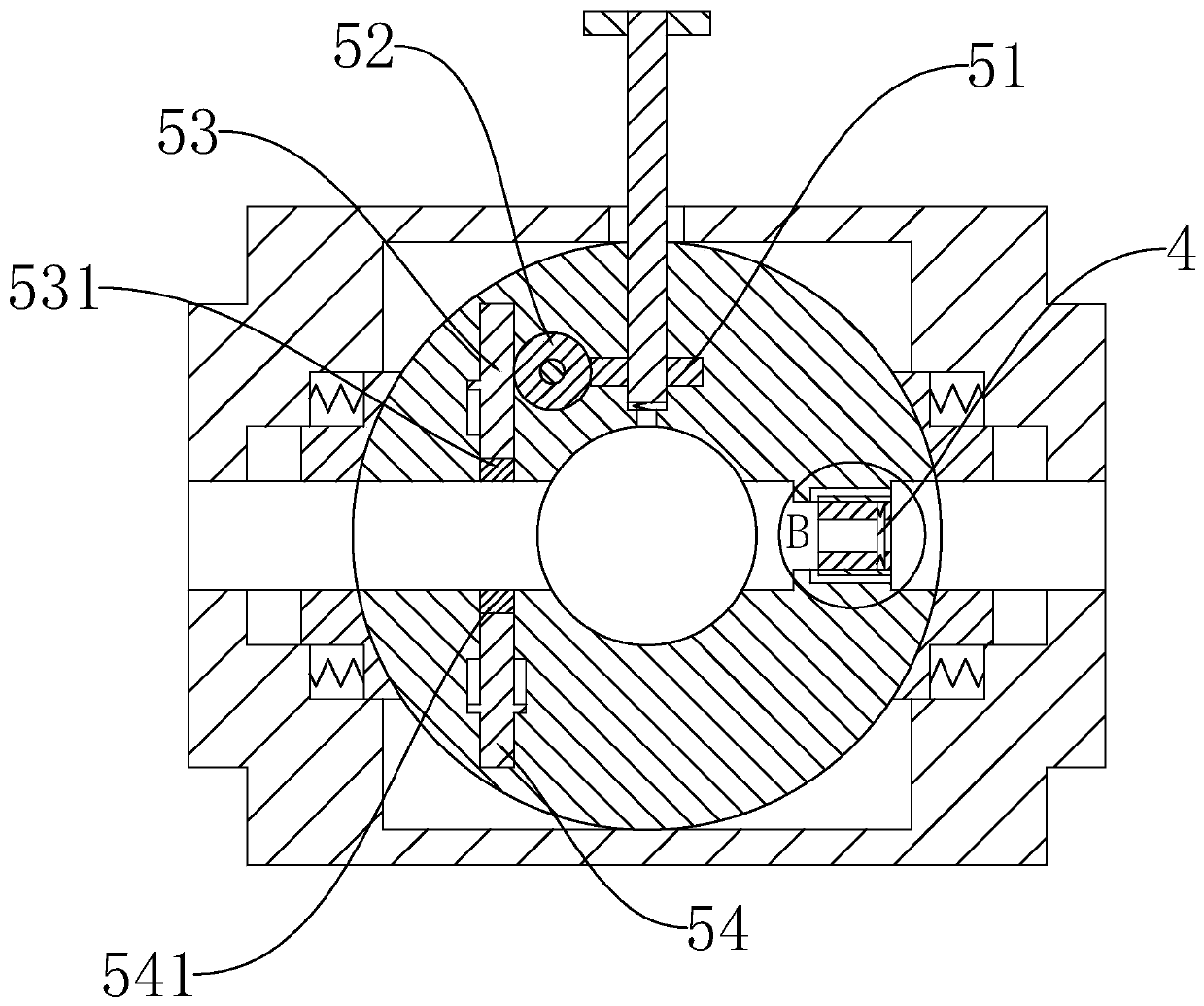

[0030] The present invention includes a valve body 1. A valve cavity is arranged inside the valve body 1. The valve cavity runs through the center of the valve core 2 horizontally. The valve cavity is provided with a water inlet 81 and a water outlet 82. The inside of the valve body 1 A ball valve 2 is provided, the valve core 2 is spherical, and a control device is provided on the ball valve 2, and a main flow channel 21 and a throttling channel communicating with each other are arranged in the valve core 2, and the control device controls the The main channel 21 or the throttling channel communicates with the water inlet 81 and the water outlet 82, and the time-limiting throttling device is provided in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com