Flanging mechanism

A technology of flanging and flanging inserts, which is applied in the field of stamping equipment, can solve problems such as scratches and burrs, and scratches and burrs on the surface of components, so as to reduce the phenomenon of flanging and improve the quality of flanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples.

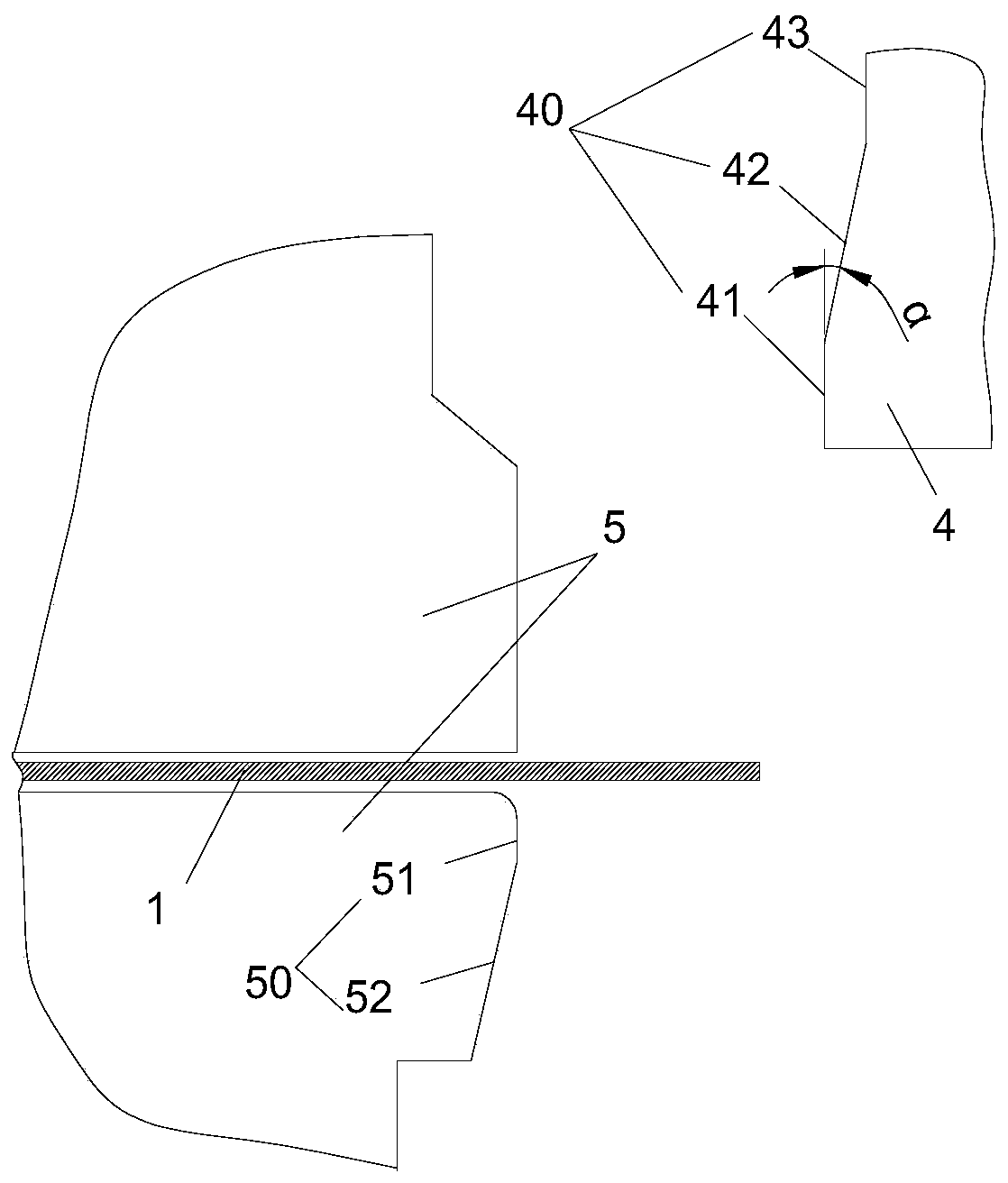

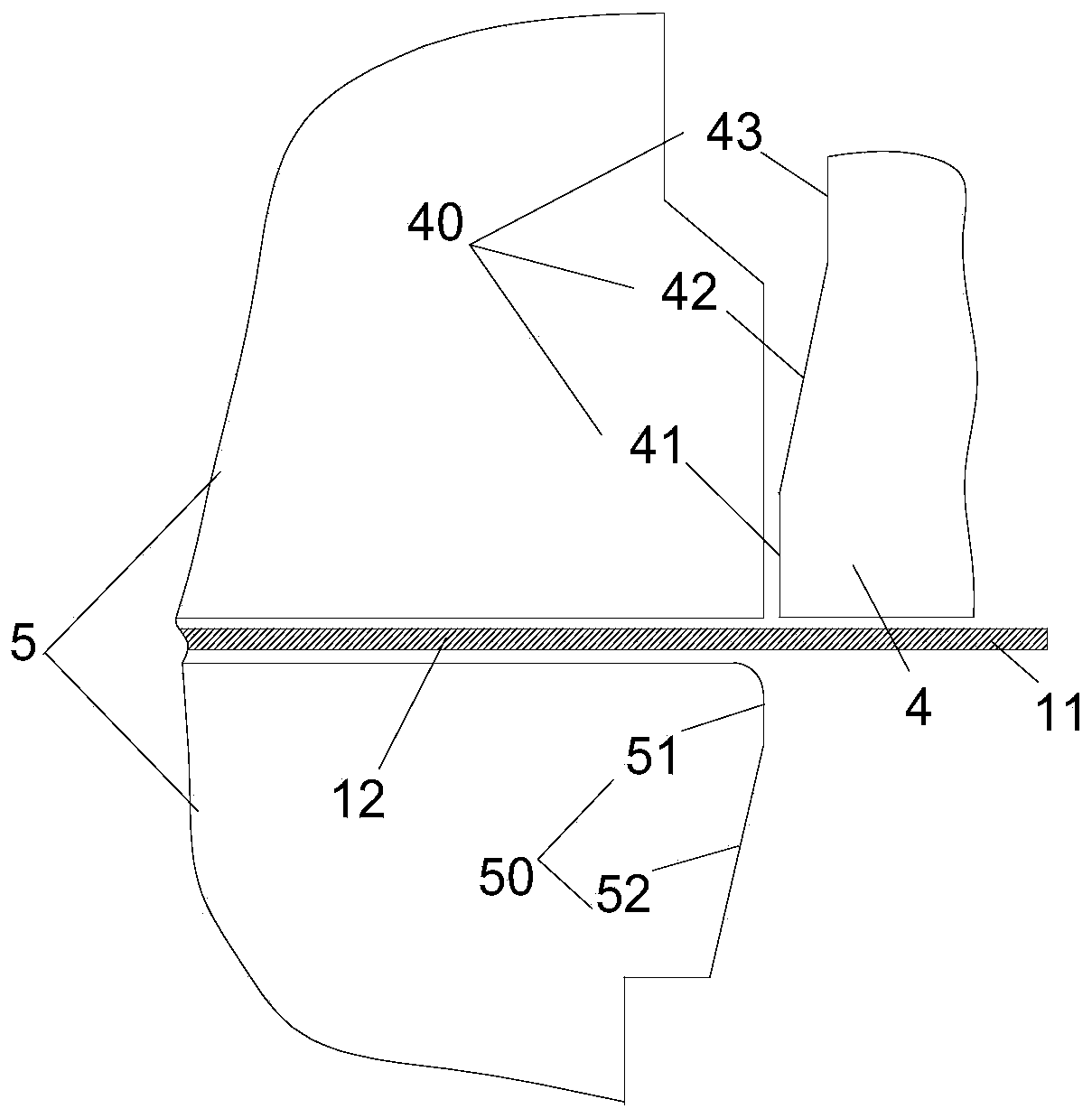

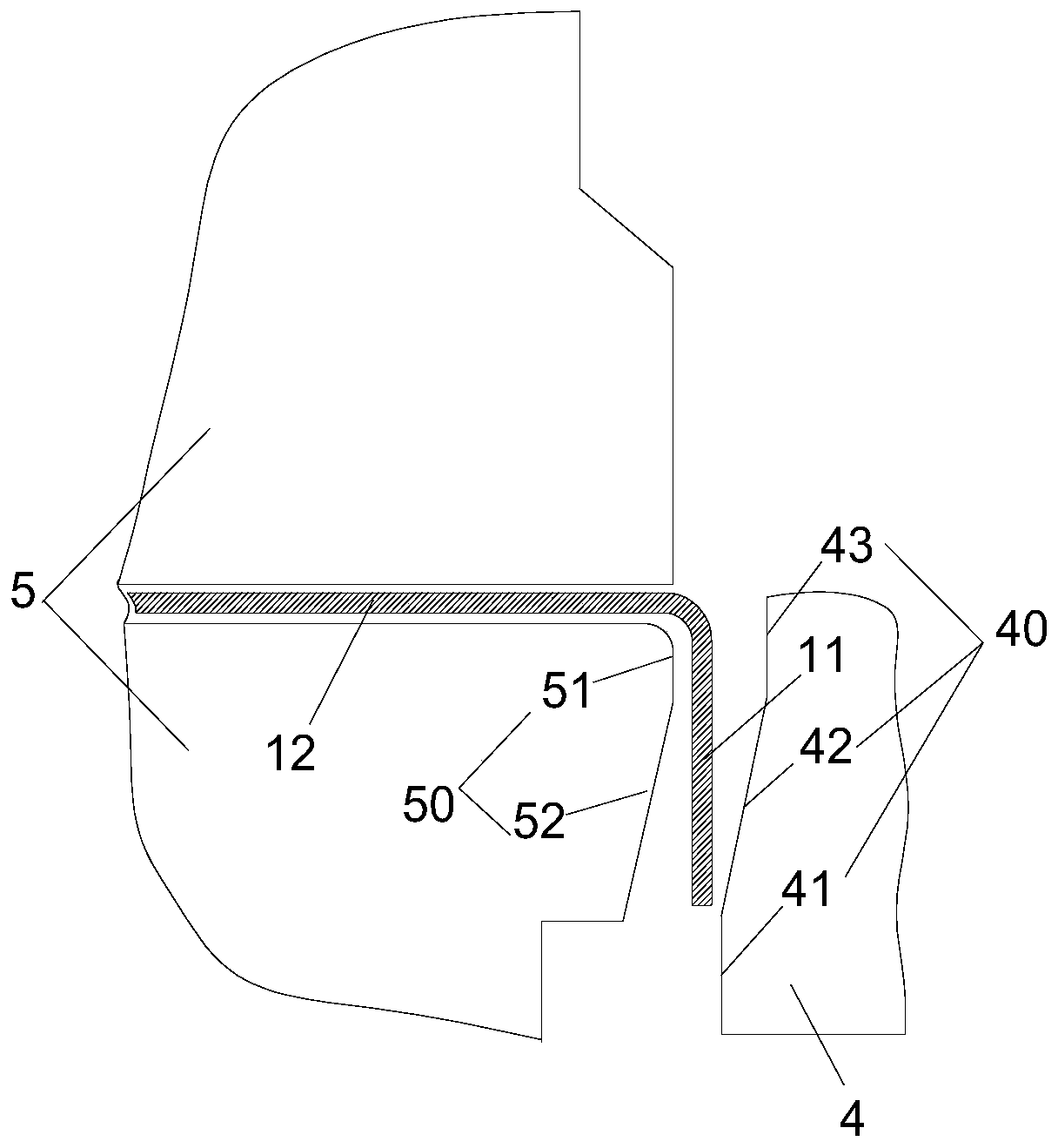

[0034] This embodiment relates to a flanging mechanism, which can constitute the vertical folding of the component edge 11 of the component 1 relative to the component body 12 of the component 1. In this embodiment, the flanging mechanism includes a fixing assembly 5 for fixing the component body 12 , also includes a base body 2, and a mounting base 3 provided on the base body 2 via a guide mechanism, the mounting base 3 can receive an external force and have a guide sliding relative to the base body 2. The flanging mechanism also includes a flanging insert 4 fixed on the mounting seat 3, and a matching component forming surface 50 and an insert forming surface 40 are respectively provided on the fixed assembly 5 and the flanging insert 4, so that The flange insert 4 can sequentially form the vertical folding of the component edge 11 relative to the compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com