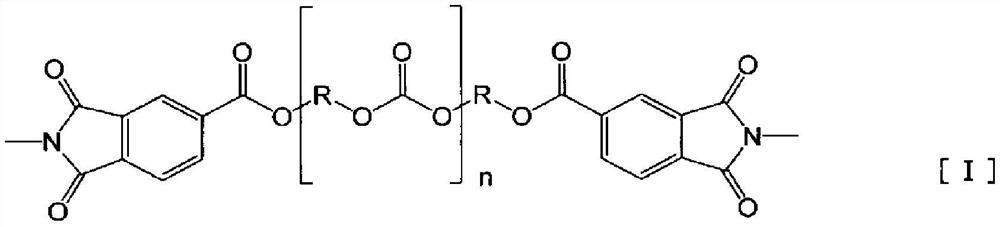

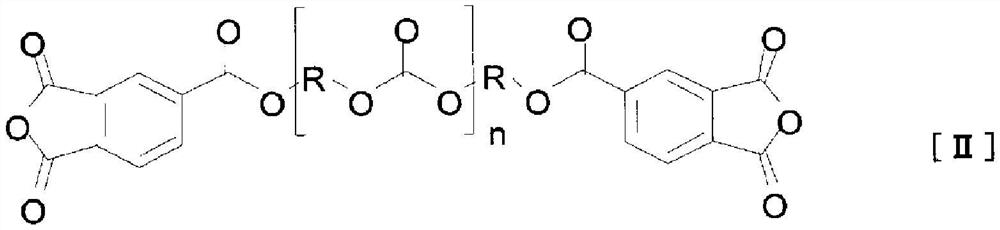

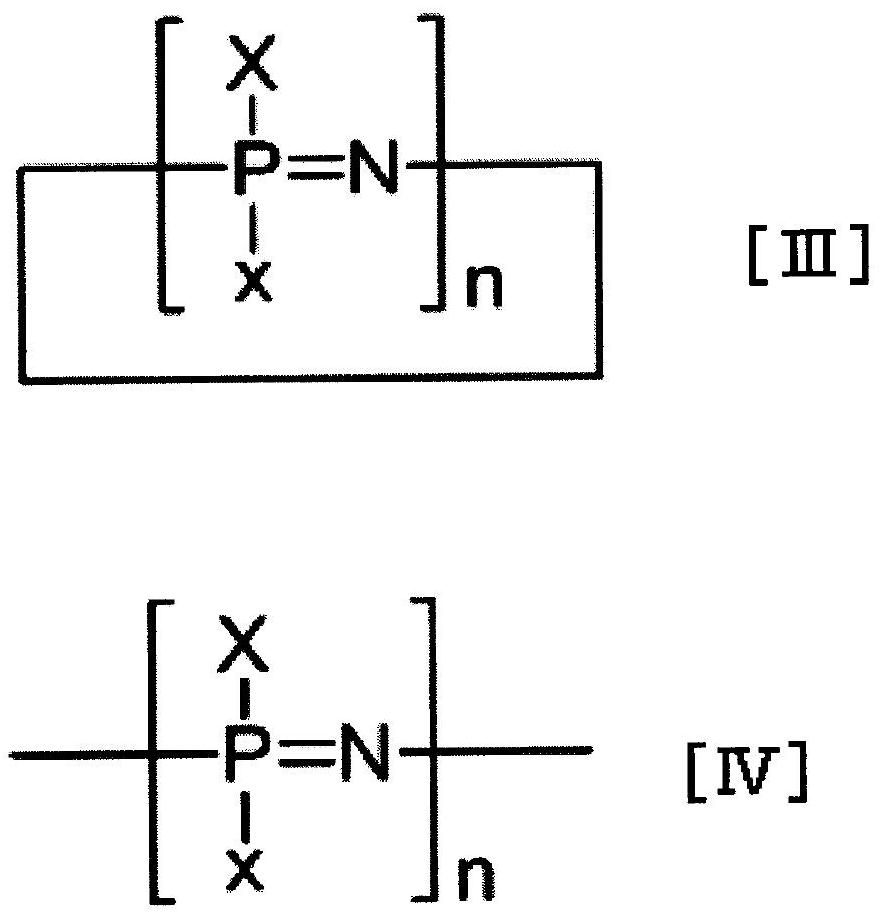

Polycarbonate imide resin and resin composition containing same

A technology of polycarbonate-imide resin and resin composition, applied in the field of polycarbonate-imide resin and adhesives using the resin, can solve the problem of high glass transition temperature, thermal deterioration of electronic parts, buried Poor ingress and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0141] The quantification of the urea structure was calculated as follows.

[0142] X={(B×F / E)×100} / (A / 2+B+B×D / C+B×F / E)

[0145] Y=G×H×K / J

[0149] ×: become hazy

[0161] The laminate after heating and curing was prepared in the same manner as in the evaluation of adhesiveness, cut into a 20 mm square, and heated at a temperature of 40° C.,

[0164]

[0165] A B-stage adhesive film was prepared in the same manner as in the evaluation of adhesiveness, and a vacuum pressure laminator was used at 160° C., 3 MPa, 30

[0169] The adhesive solution was applied to a PET film (E5101 from Toyobo Co., Ltd. with a thickness of 50 μm), so that the thickness after drying was 20 μm,

manufacture example 1

manufacture example 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com