An optical component assembly having a keyed structure for ensuring proper insertion orientation within an optical subassembly

A technology of optical subcomponents and optical components, applied in the direction of optical components, optics, electrical components, etc., can solve problems such as increased complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

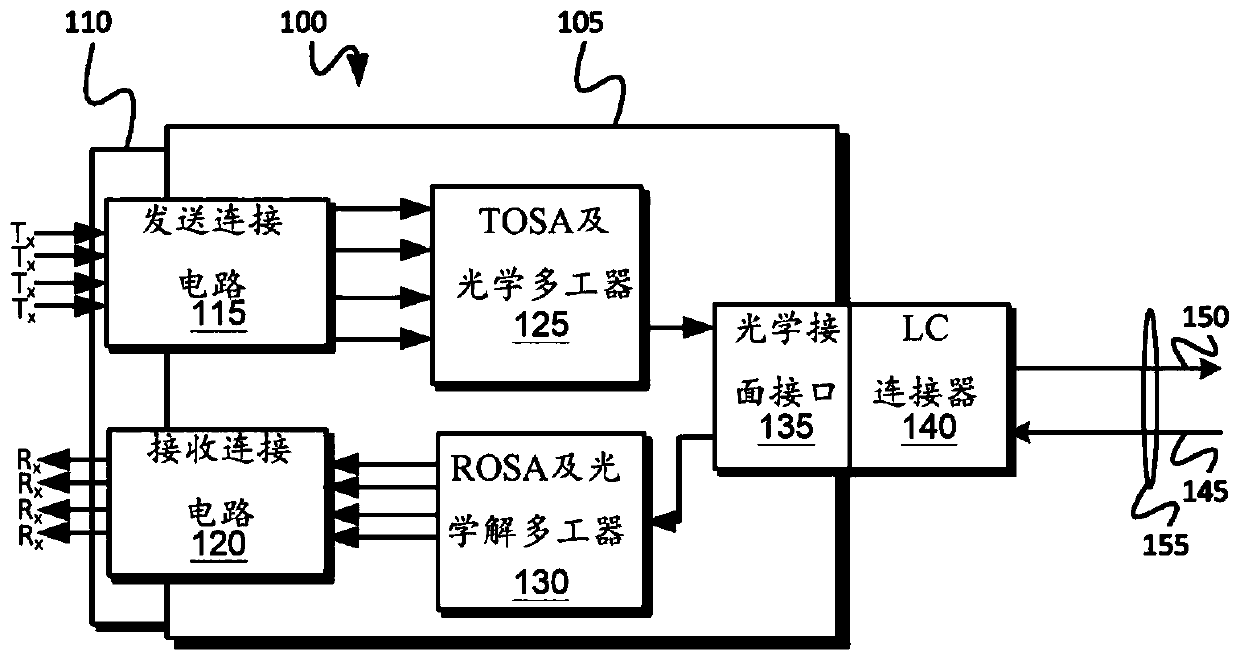

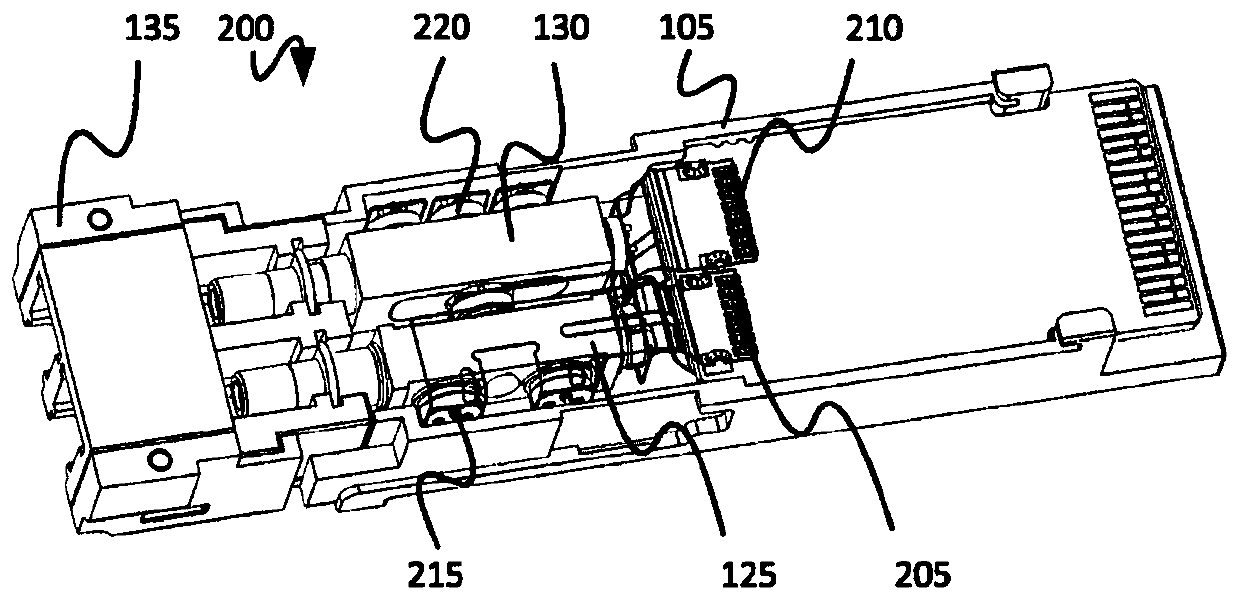

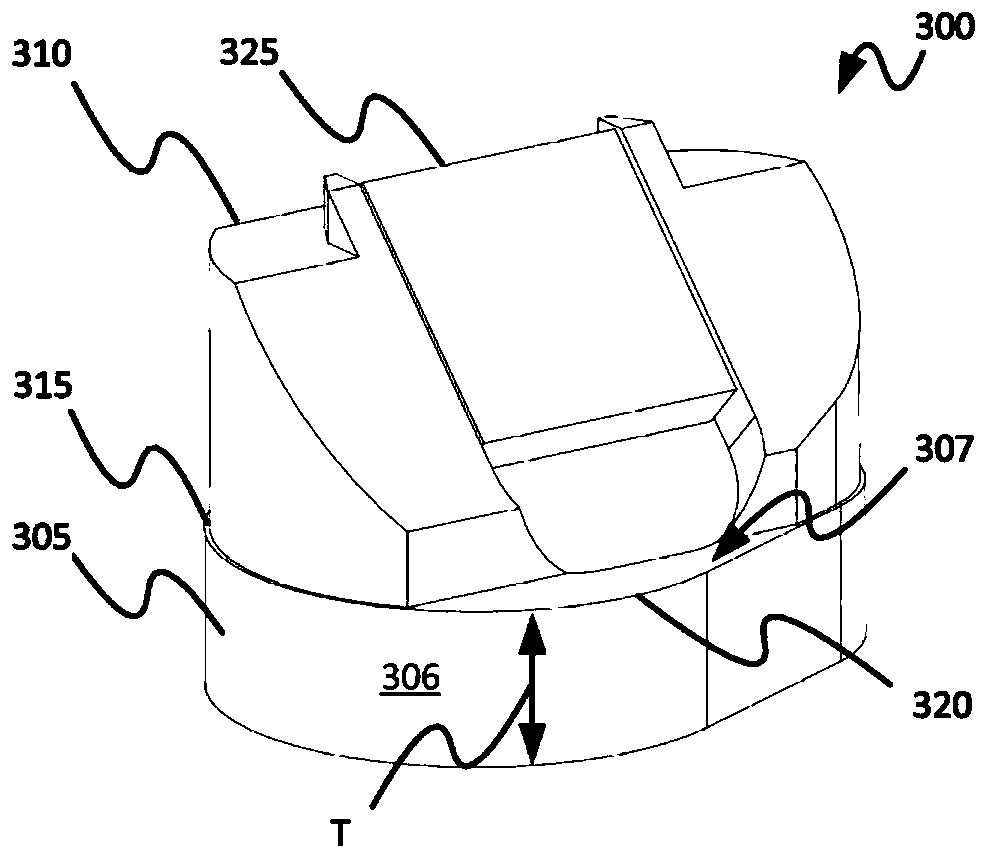

[0017] As mentioned above, the continued scaling of optical transceivers and related components presents a number of challenges that cannot be underestimated. For example, the optical component assembly can be press-fitted into an optical subassembly during manufacture, such as a transmitter optical subassembly (TOSA) and a receiver optical subassembly (TOSA) , ROSA). The optical component assembly may include a base designed to be combined with the optical subassembly housing by a press-fit, which may also be considered a friction-fit or interference-fit. fit), and this optical component assembly can further provide a mounting surface for combining with optical components, such as filters, mirrors or photodiodes. Optical components can be mounted directly to the mounting surface, or indirectly through mounts designed to hold the optical component in a specific orientation. In any case, when the optics assembly is press fit into the optics subassembly housing, the optics ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com