Mechatronic assembly controlled by a pulse-width modulation signal

A technology for electromechanical components and modulation circuits, applied in pulse generation, electrical components, control systems, etc., to solve problems that cannot be generated by the controller, cannot be used to encode direction and torque/speed information, and misinterpreted by the controller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

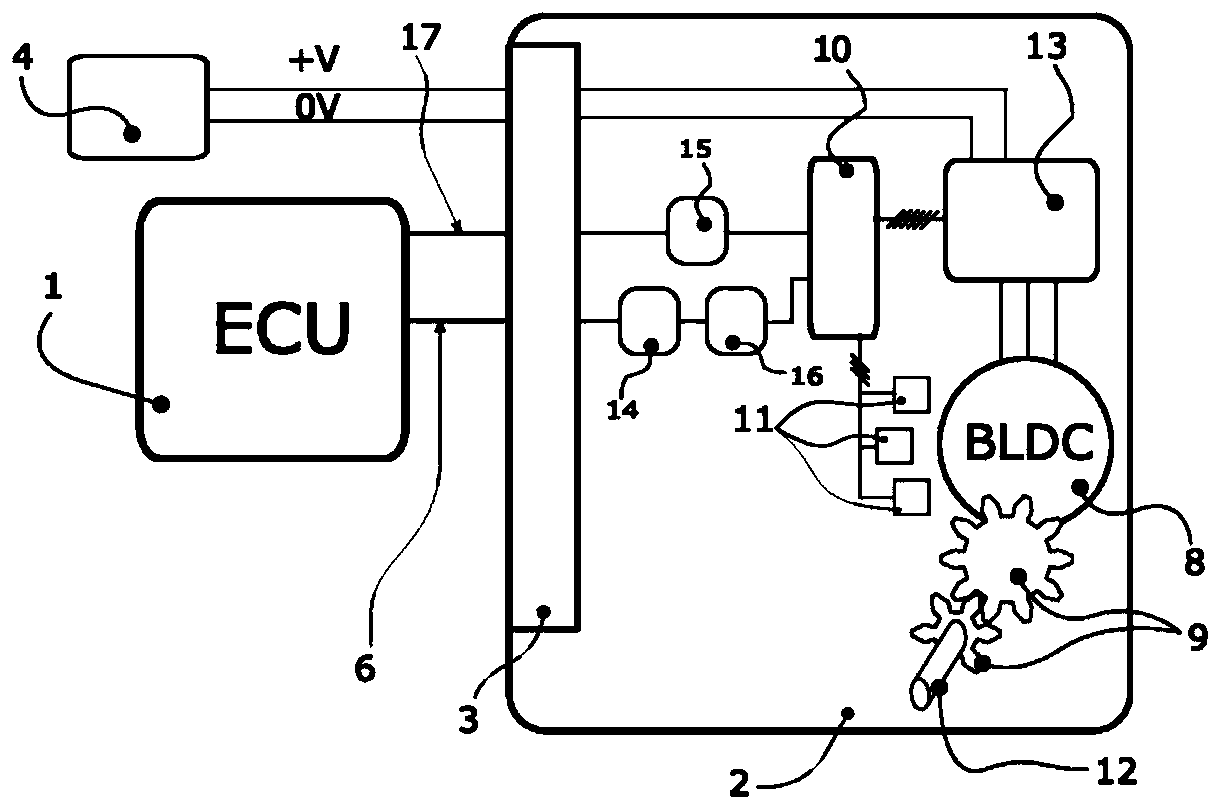

[0044] figure 1 Schematically depicts the electromechanical unit according to the invention and the elements required for its control and supply. It comprises: an electronic control unit - ECU - (1), such as a car controller; an electromechanical unit (2) according to the invention; at least one connector (3); a continuous power supply (4), such as a car battery; a Hall probe ( 11), which are usually three in number when associated with a three-phase motor, detecting the rotation of a brushless motor - or BLDC - (8) and intended to enable self-switching of the phases of the motor, the electronic control unit (1) will Steering and torque / speed information (6) is communicated to the onboard electronic drive circuit (10). The power signal from the power supply (4) is applied directly to a power bridge (13) typically comprising 6 transistors to feed the 3 phases of the BLDC motor (8). Onboard electronic drive circuit (10) whose output provides feedback to the motor (8) by combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com