A kind of camera module resolution inspection method

A camera module and inspection method technology, applied in the field of camera module quality control, can solve the problems of low resolution batch testing accuracy of camera modules, and achieve the effects of reducing the influence of horizontal and vertical differences and improving inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

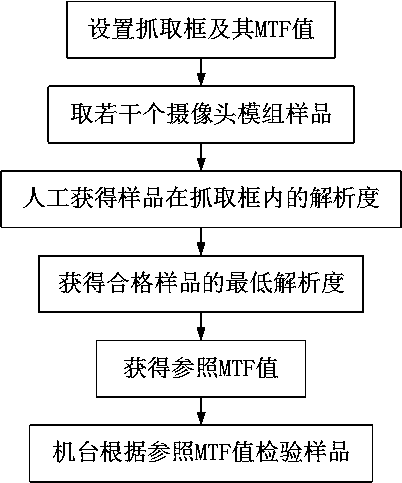

[0017] A camera module resolution inspection method, such as figure 1 As shown, the present embodiment comprises the following steps: A) setting several machine grabbing frames, and obtaining the MTF value of each grabbing frame; B) taking several camera module samples, and obtaining the Take the resolution in the frame; C) Obtain the minimum resolution of the qualified sample, and use the corresponding MTF value as the reference MTF value of each grabbing frame; D) Make each grabbing frame exceed the corresponding reference MTF value by the machine The camera module is regarded as a qualified product.

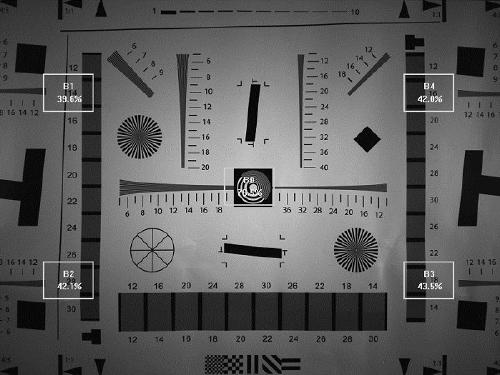

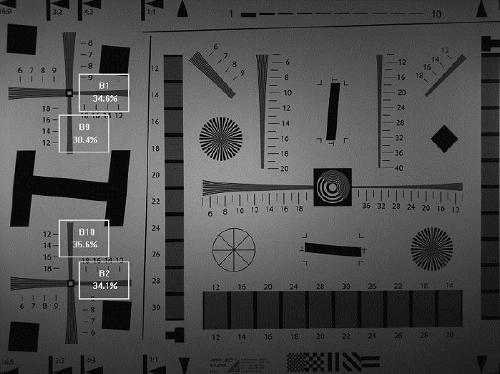

[0018] Such as figure 2 As shown, the current capture frame covers test lines in multiple directions, resulting in MTF being a combination of camera module resolutions in all directions, that is, the average value, which reduces the accuracy of the test. In this embodiment, the method for setting several grabbing frames of the machine is: set the grabbing frame of the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com