Material transportation overturning device

A technology of turning devices and materials, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of low production efficiency and high labor intensity, achieve the effect of simple structure, reduce labor intensity, and avoid manual turning of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

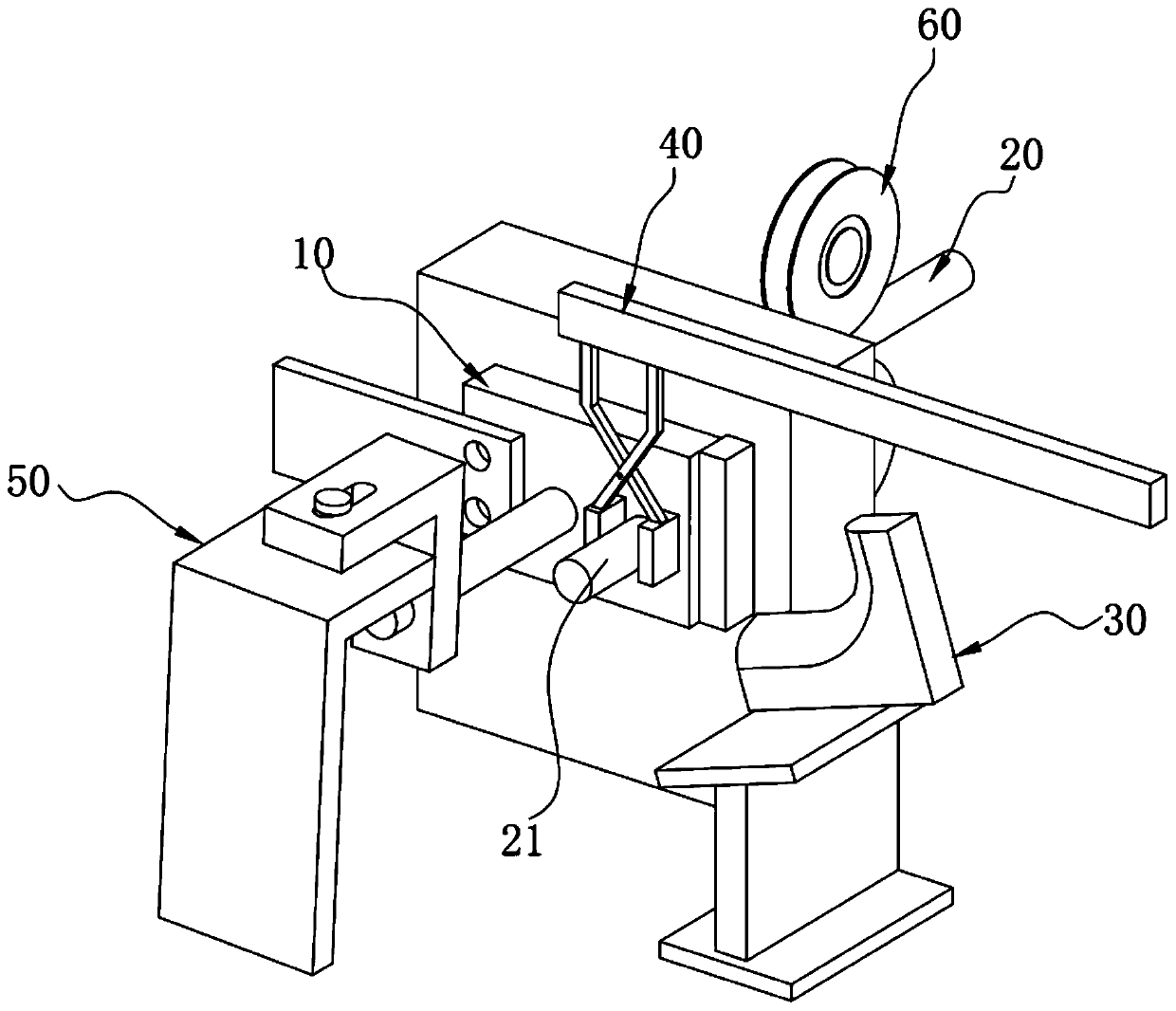

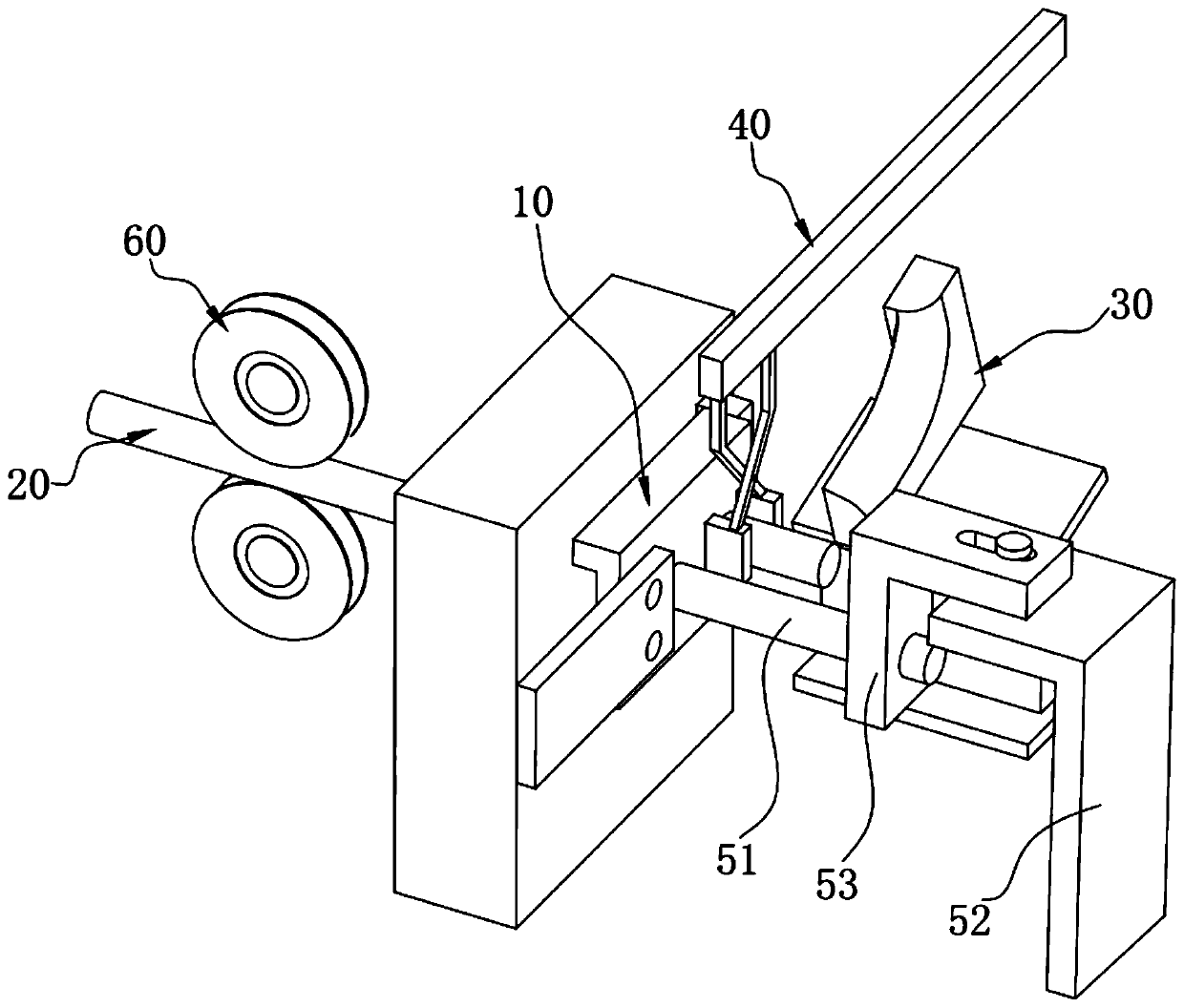

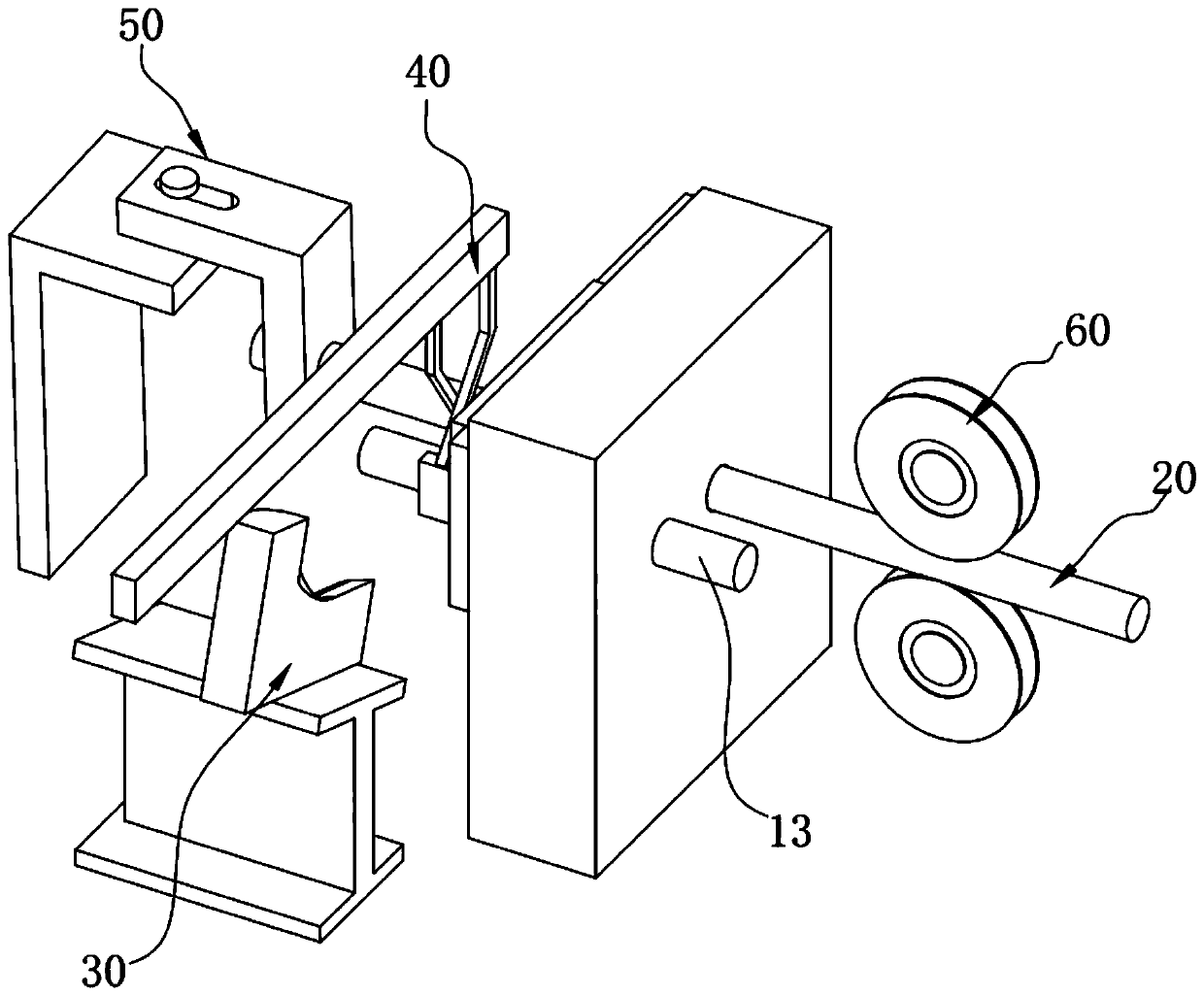

[0023] Such as Figure 1 to Figure 6 As shown, the present invention provides a material transportation overturning device, comprising: a shear die 10 arranged on a frame for cutting raw material 20, and the raw material 20 is sheared by the shear die 10 so that the central axis is in the shape of The material section 21 to be processed in a horizontal state; the gripper 40 for grasping and horizontally moving the material section 21 to be processed; arranged on the frame and positioned at one side of the shear die 10 for making the material to be processed The central axis of the section 21 changes from a horizontal state to a vertical material turning unit 30; wherein, the material turning unit 30 includes a turning block 31, and a groove is formed on the turning block 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com