Continuous propulsion mining method for converting fully mechanized caving into fully-mechanized mining for large-inclination-angle split coal seam

A mining method and a technology with a large dip angle, which are applied in the directions of surface mining, earthwork drilling, underground mining, etc., to achieve the effects of low cost, solving the increase in the gangue content of top coal caving, and improving the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the embodiments in the drawings:

[0018] The method for continuously advancing the fully mechanized caving to fully mechanized mining in the present invention for a large inclination bifurcated coal seam has the following specific steps:

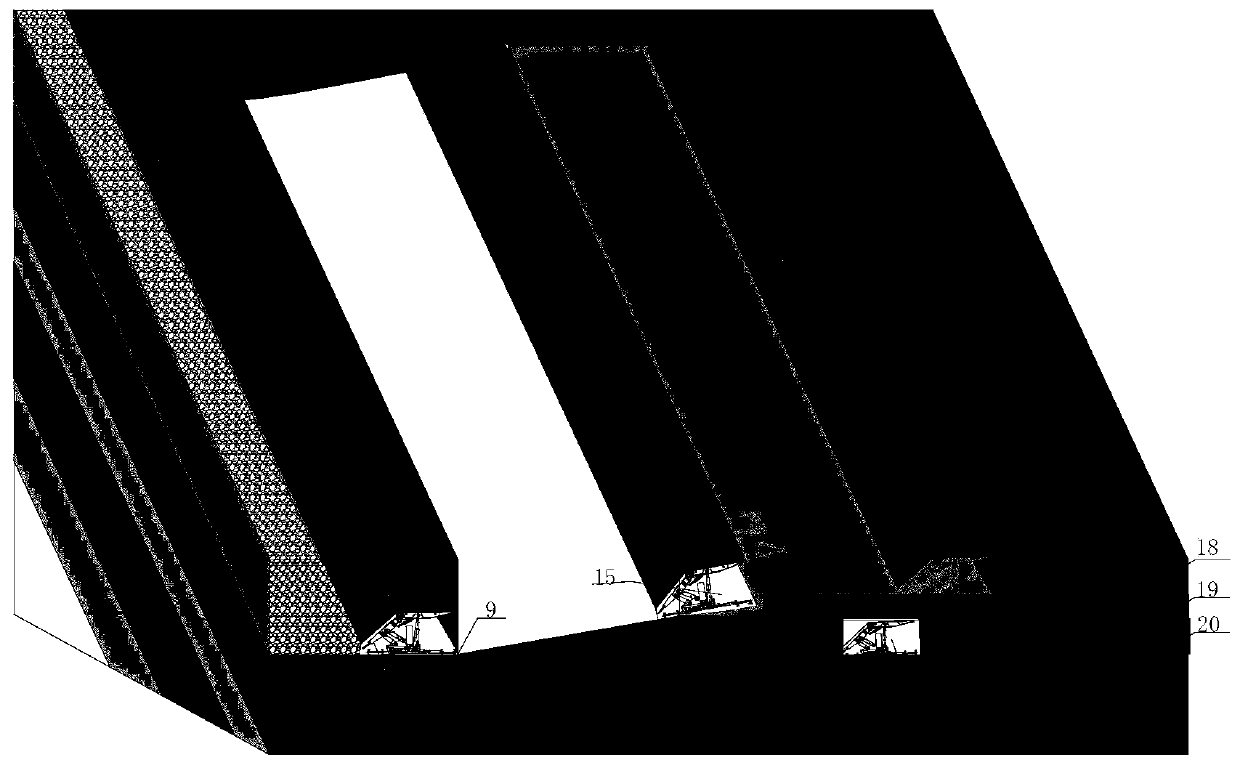

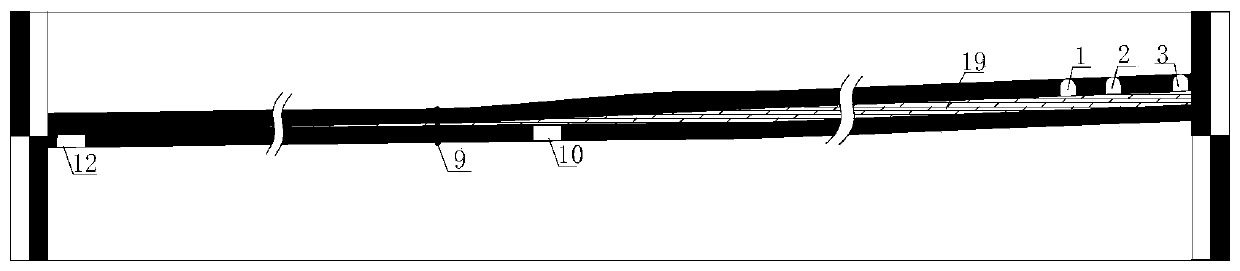

[0019] a. Cut incisions from the transportation uphill 1 and the return air uphill 3 respectively, and excavate the transportation roadway 5 and the return air roadway 4 along the roof of the coal body in the coal body, and open the cut hole of the fully mechanized caving face at the section boundary and arrange the fully mechanized caving face equipment , To form a ventilation system, and determine the location of the climbing line 9 according to the law of the influence of the gangue characteristics on the top coal caving and the principle of "the shortest two lengths and the largest angle". Advance; the "two lengths are the shortest and the other angle is the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com