Composite film and its preparation method and application

A composite film and solid-state film technology, which is applied in the field of composite films, can solve the problems of high preparation cost, low lighting voltage optimization effect of device efficiency, and single electrode optimization point, so as to reduce obstacles, improve electron mobility, and increase electronic The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

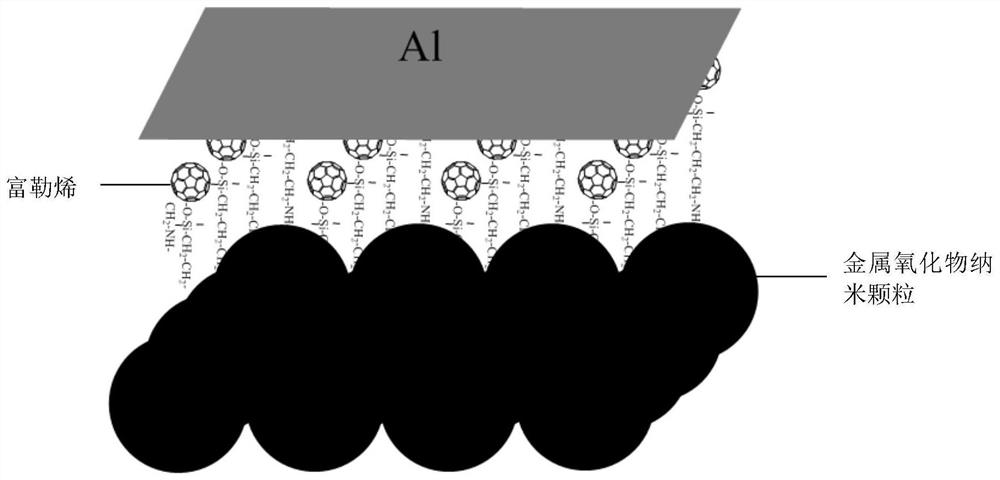

[0036] Correspondingly, a kind of preparation method of composite membrane comprises the following steps:

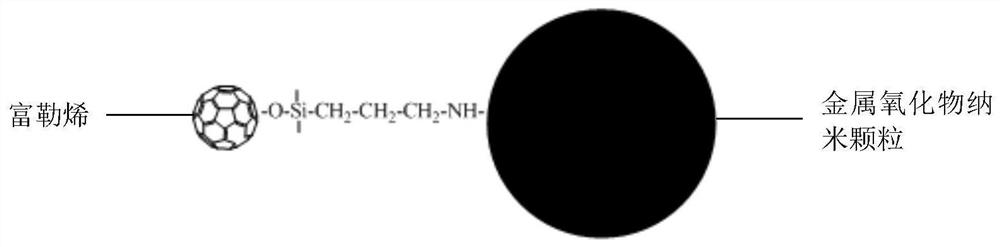

[0037] S01. Provide a metal oxide nanoparticle solution, a fullererol solution and a silane coupling agent solution, the metal oxide nanoparticle solution is alkaline, and the general formula of the silane coupling agent in the silane coupling agent solution is Y-R -Si(OX) 3 , wherein, OX is an alkoxyl group, R is selected from a hydrocarbon group or a hydrocarbon group derivative, and Y is selected from an amino group or a mercapto group;

[0038] S02. Depositing a metal oxide nanoparticle solution on the substrate, performing the first annealing treatment, and preparing a metal oxide nanoparticle solid film;

[0039] S03. After the silane coupling agent solution is deposited on the surface of the metal oxide nanoparticle solid film, the second annealing treatment is performed, and the silane coupling agent is oxidized by Y and the metal on the surface of the metal oxi...

Embodiment 1

[0075] A preparation method of composite nanoparticles, comprising the following steps:

[0076] S11.C 60 (OH) 36 was prepared as follows:

[0077] Add 10 mL (20 mmol / ml) of NaOH solution to the flask, and dropwise add 0.5 mL (10%) tetrabutylammonium hydroxide TBAH solution. With vigorous stirring, 12 mL containing 20 mg C 60 Toluene solution, then dropwise added 1ml (30%) of H 2 o 2 The solution was stirred for 2 hours. After standing still, the reaction mixture was divided into two layers, the upper layer was a colorless organic phase, and the lower layer was a brown-black aqueous phase. Liquid separation, filtration to remove insoluble matter in the water phase, to obtain a brown-black solution. Add methanol, precipitate (orange), and centrifuge to remove methanol; add water to dissolve the precipitate, then add methanol to precipitate, and repeat this 3-4 times until NaOH and TBAH are completely washed away. The resulting precipitate was vacuum-dried at room temper...

Embodiment 2

[0086] A QLED device, comprising a laminated and combined transparent anode, a quantum dot light-emitting layer, an electron transport layer and a cathode, the electron transport layer being the composite film prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com