Diesel engine sequential supercharging system and control method with slow start function

A technology of successive supercharging and control methods, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problems of zero flow of supercharger compressor, compressor mechanical damage, deep surge, etc., and achieve intake pressure. Small fluctuations, improved operating conditions, improved effect of transient processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

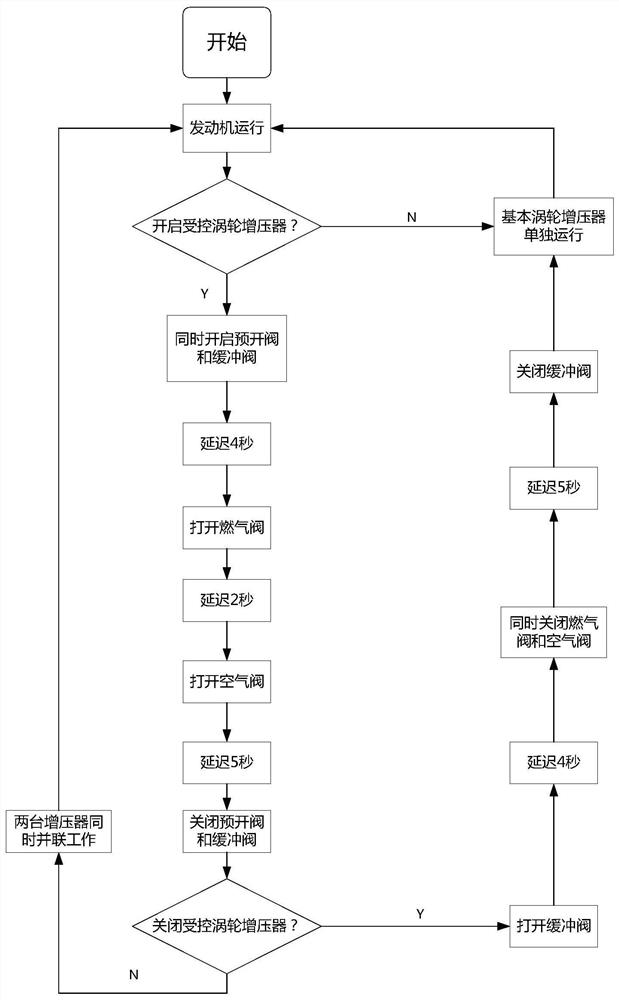

[0014] The present invention will be described in more detail below in conjunction with the accompanying drawings:

[0015] combine Figure 1-2 , the present invention includes diesel engine 7, diesel engine intake pipe 6, diesel engine exhaust pipe 8, intercooler 5, exhaust manifold 11, air filter 1, basic supercharger 9, air valve 4, gas valve 12, buffer valve 10. Pre-open valve 2, etc. The outlet of the basic supercharger turbine, the outlet of the controlled supercharger turbine 13 and the end leading to the atmosphere are connected in the form of a tee. One end of the air valve 4 is connected to the intercooler 5 , and the other end is connected to the outlet of the compressor of the controlled supercharger and one end of the buffer valve 2 in a three-way manner. One end of the pre-opening valve 10 is connected to the exhaust manifold 11 , the other end is connected to the inlet of the controlled supercharger turbine 13 and one end of the gas valve 12 in the form of a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com