A kind of ESD testing tool and testing method of camera module

A technology of camera module and test tool, applied in the direction of measuring electricity, measuring device, image communication, etc., can solve the problems of inaccurate results and erroneous discharge, so as to ensure product quality, increase electric contact area, and reduce erroneous discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

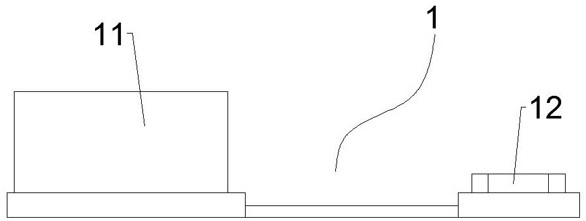

[0028] Such as figure 1 As shown, the camera module 1 includes a camera 11 and a connector 12, the camera 11 is mounted on the first PCB, the connector 12 is mounted on the second PCB, and the first PCB and the second PCB pass through An FPC is electrically connected; the connector 12 has multiple connection pins.

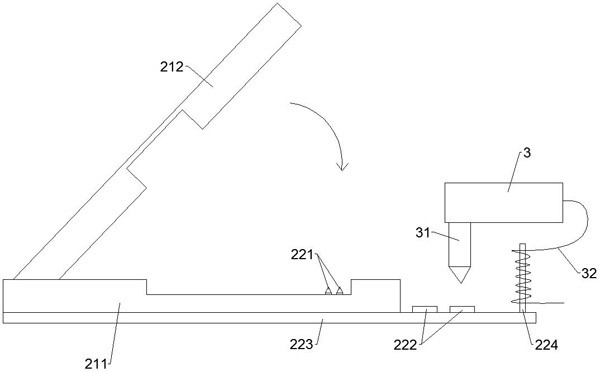

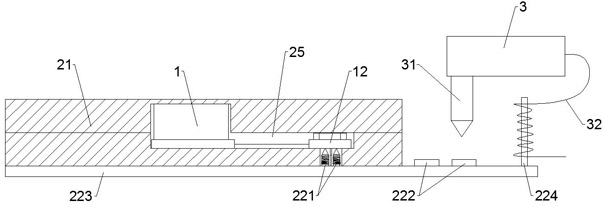

[0029] Such as figure 2 and 3 As shown, a kind of ESD testing tool of camera module 1, comprises:

[0030] The fixing part 21 is used to fix the camera module 1 to be tested;

[0031] The electrical connection discharge part includes a plurality of electrical connectors 221 for electrically contacting correspondingly with each connection pin on the camera module 1 to be tested, and a device for electrically contacting the tip 31 of the electrostatic gun 3 for ESD testing. A plurality of discharge parts 222, the discharge parts 222 and the electrical connection parts 221 are electrically connected in one-to-one correspondence;

[0032] Wherein, the distance be...

Embodiment 2

[0040] An ESD testing method for camera module 1, comprising:

[0041] Step 1: provide the ESD testing tool described in embodiment one;

[0042] Step 2: Fix the camera module 1 to be tested on the fixing part 21, so that each connecting pin on the camera module 1 to be tested is in electrical contact with the corresponding electrical connector 221;

[0043] Step 3: ESD testing is performed by using the electrostatic gun 3 to make electrical contact with each discharge device 222 in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com