Beam-after-cable self-anchored suspension bridge design and construction method

A technology of self-anchored suspension bridge and construction method, which is applied in the direction of suspension bridge, bridge form, bridge construction, etc., can solve the problems of self-anchored suspension bridge span increase, etc., and achieve the effects of improving competitiveness, facilitating monitoring, and clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] In order to describe the present invention in more detail, the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

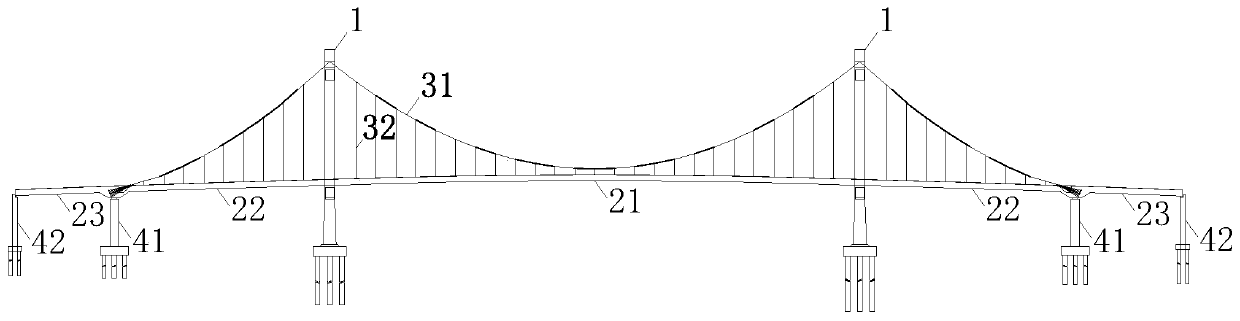

[0035] Such as figure 1 Shown here is a typical double-tower five-span self-anchored suspension bridge. The structure includes: pylon 1, pier (including auxiliary pier 41 and transition pier 42), main beam (including main span main beam 21, side span main beam 22 and anchor span main beam 23), main cable 31 and sling 32, etc.

[0036] From figure 1 The self-anchored suspension bridge is in a reasonable state. It can be seen that since the main cable 31 of the self-anchored suspension bridge is anchored to the main girder, when the main girder acts on the vertical load, the main cable 31 has a relatively large horizontal force. The component force will be borne by the main beam. The state of the structure during the construction process is not exactly the same as ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap