Reduction device and method for producing and reducing iron powder from iron concentrate powder

A technology for reducing iron powder and iron ore concentrate, applied in the field of metallurgy, can solve the problems of ineffective utilization of waste heat, high impurity content in products, complex production process, etc., and achieve good environmental and economic benefits, high energy utilization, and improved The effect of product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

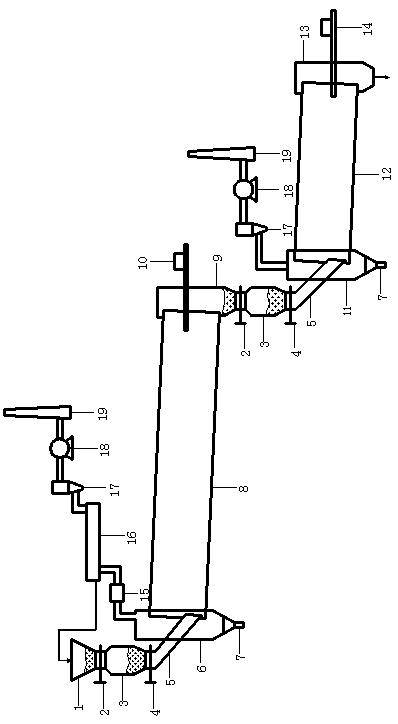

[0032] The iron concentrate with TFe=71%, particle size -150 mesh and 11% water content is evenly distributed on the steel belt of the steel belt drying furnace. The material is dried by the high-temperature tail gas from the rotary kiln and then enters the raw material bin. It is countercurrent to the direction of airflow. After the dried flue gas passes through the bag filter, it is introduced into the chimney by the intake fan to meet the standard discharge, and the bag dust is returned to the raw material warehouse for recycling.

[0033] Adjust the upper flap valve so that the material enters the intermediate silo, at the same time close the upper flap valve and open the lower flap valve so that the material enters the rotary kiln along the chute.

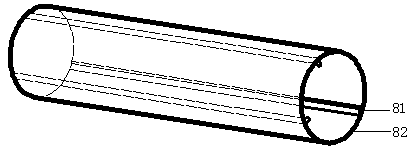

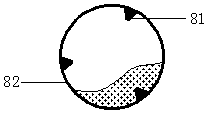

[0034] The material turns over and moves forward in the rotary kiln. The rotating speed of the rotary kiln is 0.5r / min. There are 2 turning plates in the rotary kiln. The rotary kiln adopts electric heating, and the temperature...

Embodiment 2

[0041] The iron ore concentrate with TFe=71.5%, particle size -200 mesh, and 8% water content is evenly distributed on the steel belt of the steel belt drying furnace. The material is dried by the high-temperature tail gas from the rotary kiln and then enters the raw material bin. It is countercurrent to the direction of airflow. After the dried flue gas passes through the bag filter, it is introduced into the chimney by the intake fan to meet the standard discharge, and the bag dust is returned to the raw material warehouse for recycling.

[0042]Adjust the upper flap valve so that the material enters the intermediate silo, at the same time close the upper flap valve and open the lower flap valve so that the material enters the rotary kiln along the chute.

[0043] The material turns over and moves forward in the rotary kiln. The rotating speed of the rotary kiln is 1.5r / min. There are 3 turning plates in the rotary kiln. The rotary kiln adopts electric heating, and the temper...

Embodiment 3

[0050] The iron concentrate with TFe=71.5%, particle size -250 mesh, and 8% water content is evenly distributed on the steel belt of the steel belt drying furnace. The material is dried by the high-temperature tail gas from the rotary kiln and then enters the raw material bin. It is countercurrent to the direction of the airflow. After the dried flue gas passes through the bag filter, it is introduced into the chimney by the intake fan to meet the standard discharge, and the bag dust is returned to the raw material warehouse for recycling.

[0051] Adjust the upper flap valve so that the material enters the intermediate silo, at the same time close the upper flap valve and open the lower flap valve so that the material enters the rotary kiln along the chute.

[0052] The material turns over and moves forward in the rotary kiln. The rotating speed of the rotary kiln is 3r / min. There are 4 turning plates in the rotary kiln. The rotary kiln adopts electric heating, and the tempera...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap