General preparation method of metal oxide nanosheets

An oxide and nanosheet technology, applied in the field of materials, can solve problems such as poor controllability, and achieve the effects of low cost, less product impurities and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

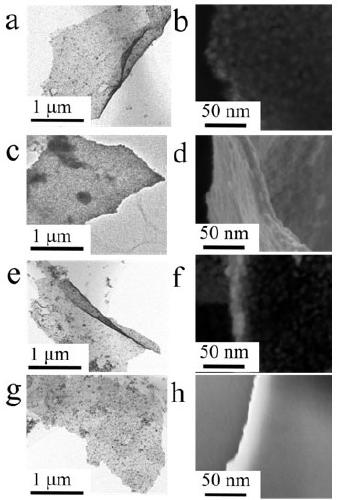

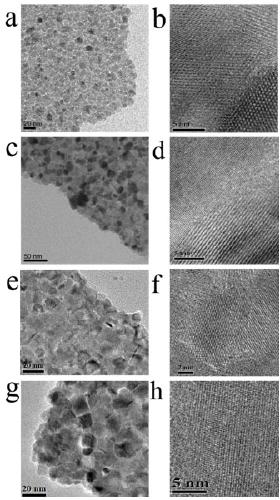

[0015] (1) Add 4 grams of glucose and 200 mg of manganese acetate to 10 ml of deionized water, stir well to form a uniform solution;

[0016] (2) Heat the solution obtained in (1) in a tube furnace at 350°C for 20 minutes, then raise the temperature to 400°C at a heating rate of 10°C / min, and keep it at this temperature for 2 hours to obtain manganese oxide nanoparticles piece. Before heating, the tube furnace has been heated to 350°C, and there is no heating step in the solution heating process; the heating is carried out in air. After heating, the samples were cooled naturally in air.

Embodiment 2

[0018] (1) Add 3 grams of glucose and 200 mg of iron acetate to 10 ml of deionized water, and stir thoroughly to form a uniform solution;

[0019] (2) Heat the solution obtained in (1) in a tube furnace at 350°C for 20 minutes, then raise the temperature to 500°C at a heating rate of 10°C / min, and keep it at this temperature for 2 hours to obtain iron oxide nanoparticles piece. Before heating, the tube furnace has been heated up to 350 o C, There is no heating step in the solution heating process; the heating is carried out in air. After heating, the samples were cooled naturally in air.

Embodiment 3

[0021] (1) Add 3.5 grams of glucose and 200 mg of cobalt acetate to 10 ml of deionized water and stir thoroughly to form a uniform solution;

[0022] (2) Heat the solution obtained in (1) in a tube furnace at 350°C for 20 minutes, and then heat it with 10 o The temperature was raised to 400° C. at a heating rate of C / min, and kept at this temperature for 2 hours to obtain cobalt oxide nanosheets. Before heating, the tube furnace has been heated to 350°C, and there is no heating step in the solution heating process; the heating is carried out in air. After heating, the samples were cooled naturally in air.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap