Limited tube moving machine

A technology of displacement tube and frame, applied in the direction of crane, traveling mechanism, trolley crane, etc., can solve the problems of inversion, tube transfer machine hitting both ends of gantry frame, poor braking effect, etc., and achieve the effect of preventing hard collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

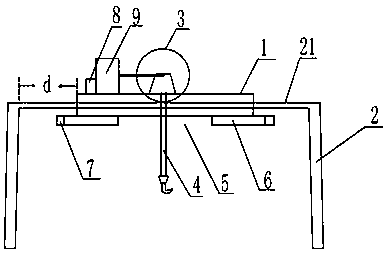

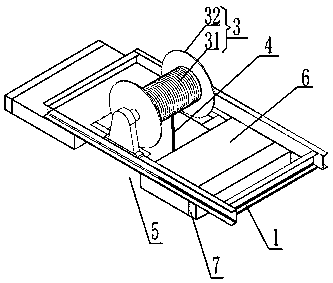

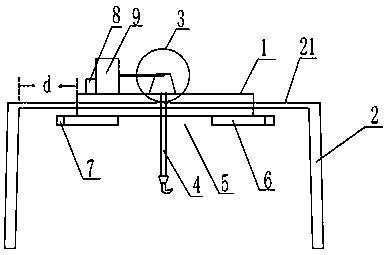

[0018] attached figure 1 And attached figure 2 It is a specific embodiment of the present invention. A displacement-limiting tube machine, comprising a frame (1), the frame (1) is slidably arranged on the beam (21) of the gantry (2), and the frame (1) is provided with a motor-driven A reel (3), the reel (3) is wound with a steel wire rope (4), and the position of the frame (1) corresponding to the reel (3) is provided with an avoidance area for avoiding the steel wire rope (4) (5), the bottom of the frame (1) is provided with a slide plate (6) for adjusting the size of the avoidance area (5), the slide plate (6) can slide horizontally along the frame (1), and the slide plate (6) Limiting elastic pads (7) are provided on the sides near the two ends of the beam of the gantry (2);

[0019] Both ends of the frame (1) along the extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com