Coal and rock mass conductive fracturing device based on liquid carbon dioxide

A liquid carbon dioxide, coal and rock mass technology, applied in the direction of discharge machinery, earthwork drilling and mining, etc., can solve the problems of inability to adjust the direction of the energy discharge port, the inability to change the exhaust direction, and inaccurate blasting, so as to avoid horizontal exhaust , Disassembly and installation are convenient, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

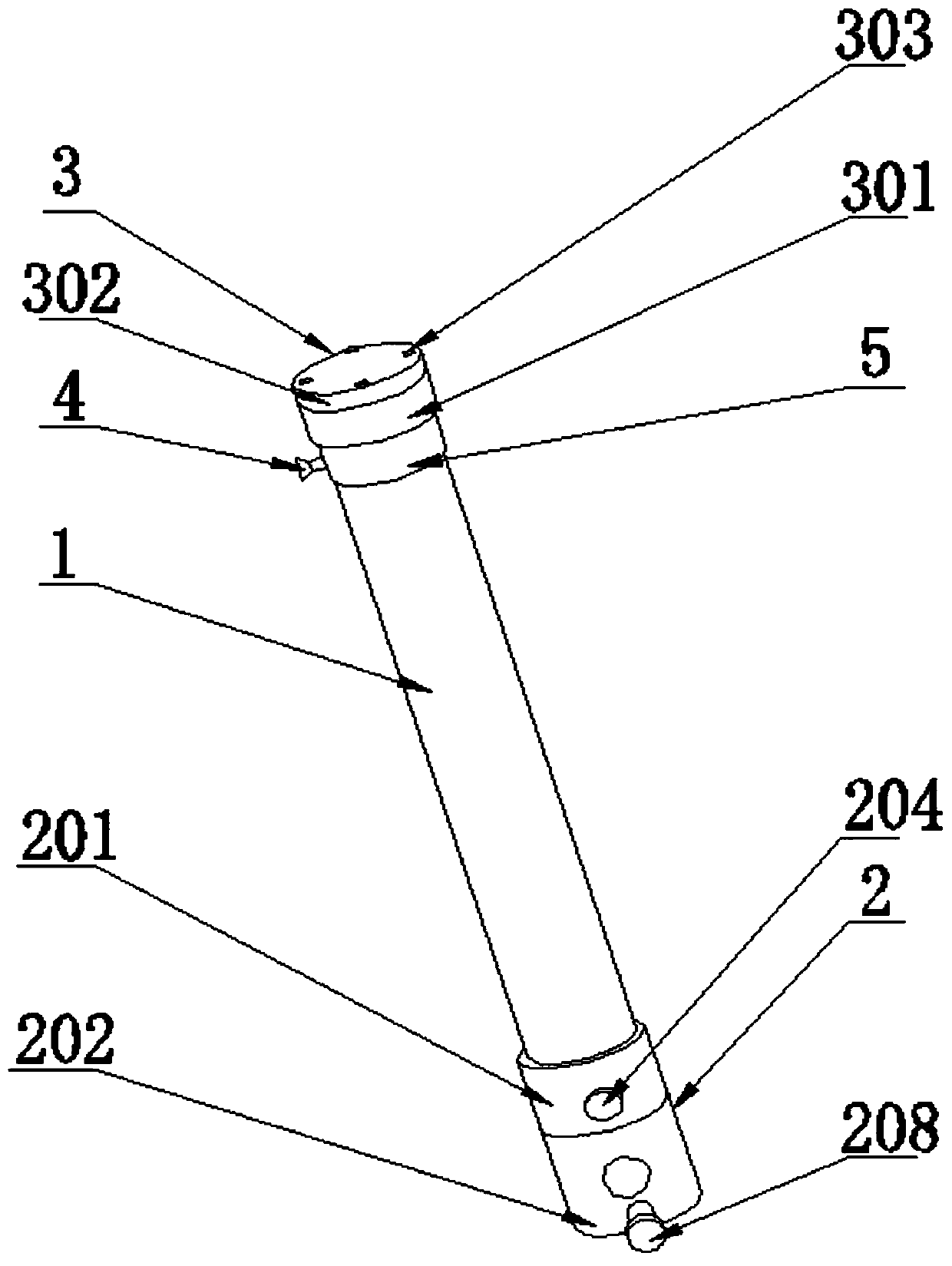

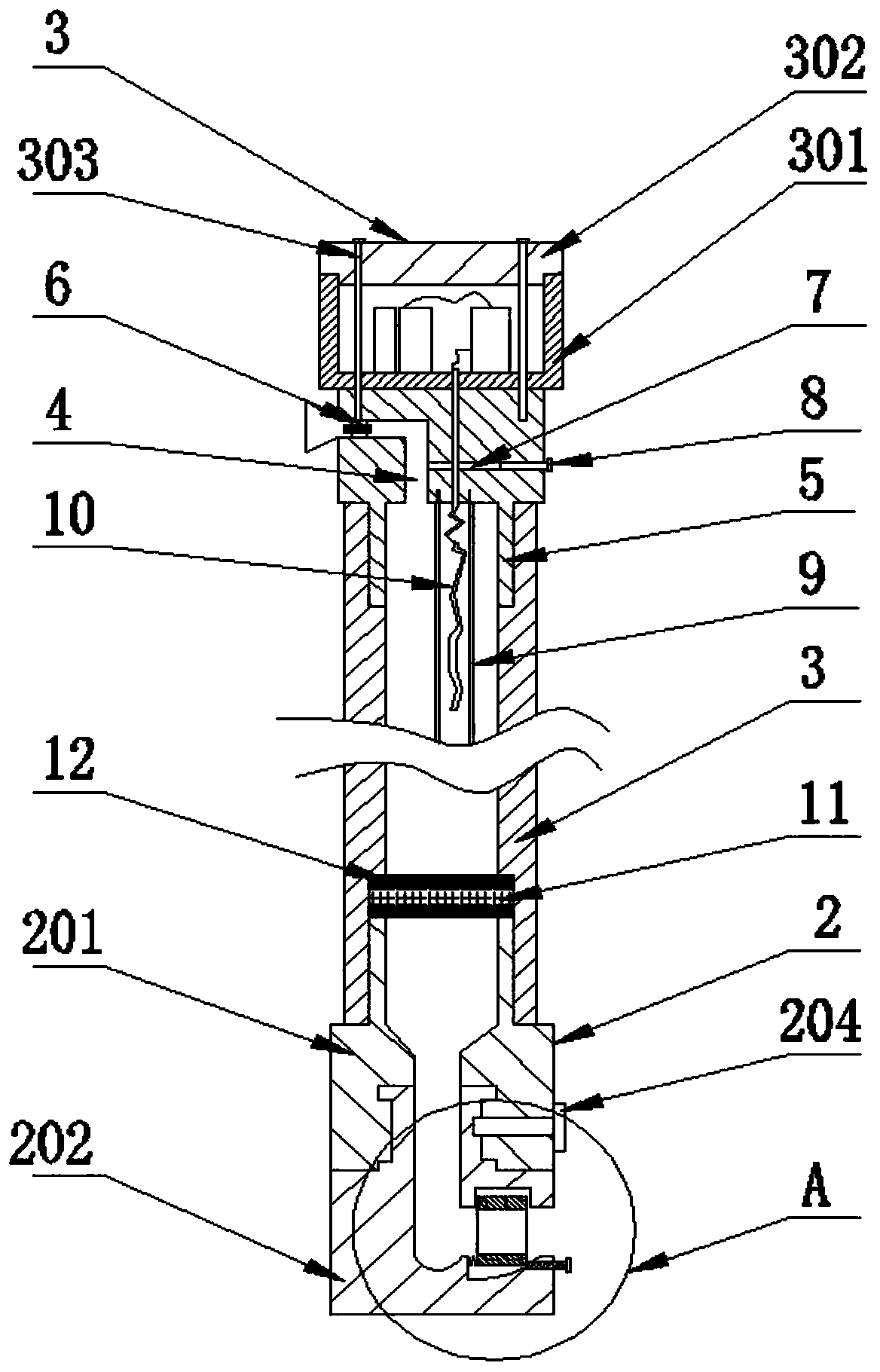

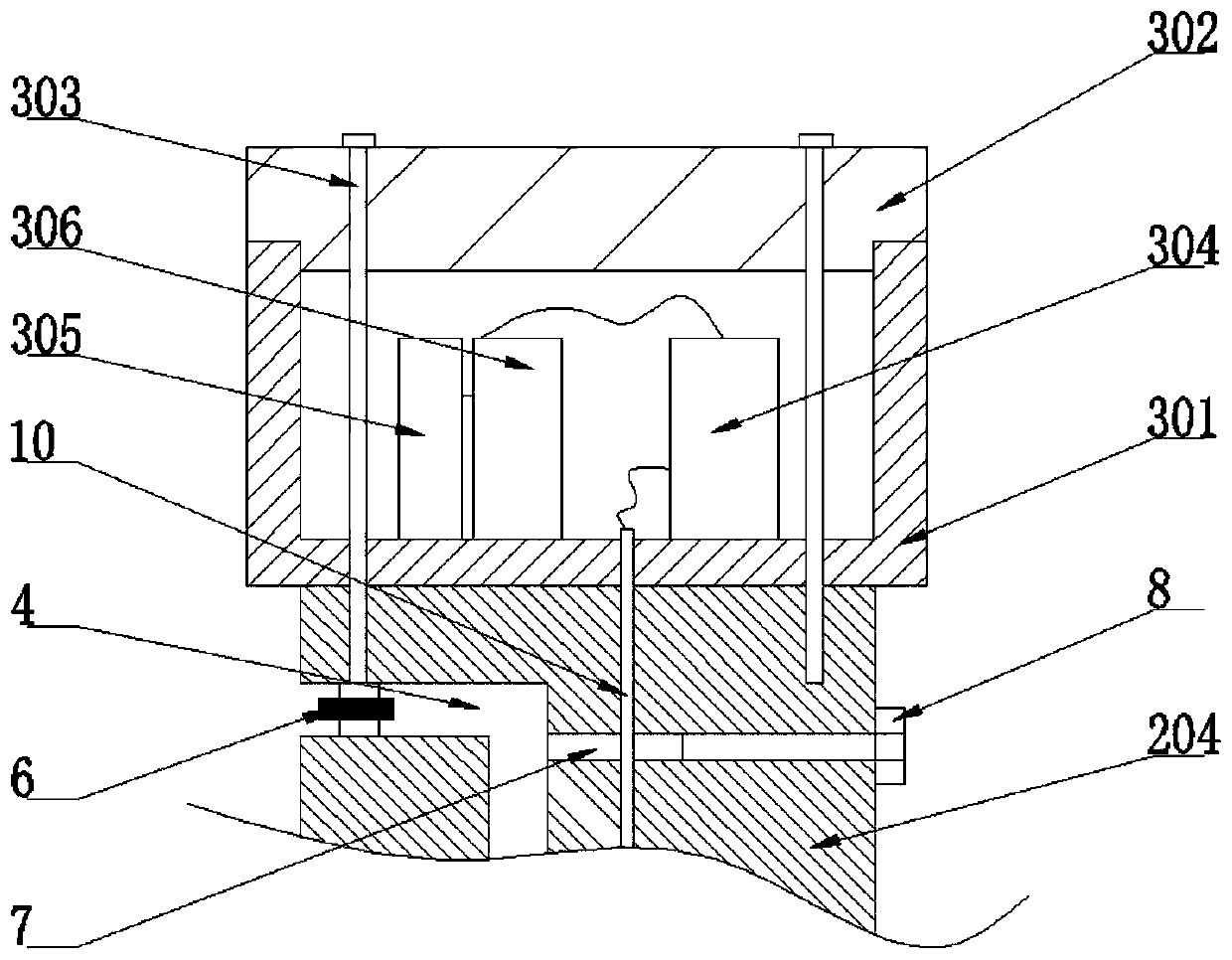

[0021] see Figure 1~4 , in an embodiment of the present invention, a coal-rock mass conduction fracturing device based on liquid carbon dioxide, comprising a storage tank 1, the upper end of the storage tank 1 is threadedly connected with a filling head 5, and the lower end of the storage tank 1 is threadedly connected with a drain The energy mechanism 2, the bottom end of the storage tank 1 is provided with a shear sheet 11, the upper and lower surfaces of the shear sheet 11 are provided with a sealing gasket 12, the filling head 5 is provided with an inflation hole 4, and the upper surface of the filling head 5 is fixed A remote control mechanism 3 is installed, a one-way valve 6 is installed in the inflation hole 4, an exhaust hole 7 is opened on one side of the filling head 5, the front end of the exhaust hole 7 is connected to the inflation hole 4, and a sealing device is arranged in the exhaust hole 7 The plug 8 and the lower surface of the filling head 5 are threadedly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap