Gear adjusting tool of dry type transformer and using method of tool

A technology of dry-type transformers and tools, which is applied in the direction of manufacturing tools, wrenches, screwdrivers, etc., which can solve the problems of potential safety hazards, small space in the transformer room, and difficulty in picking up bolts, gaskets, and shifting connecting pieces, so as to avoid accidental slipping , Eliminate potential safety hazards, convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] The present invention will be further explained below in conjunction with the drawings and embodiments:

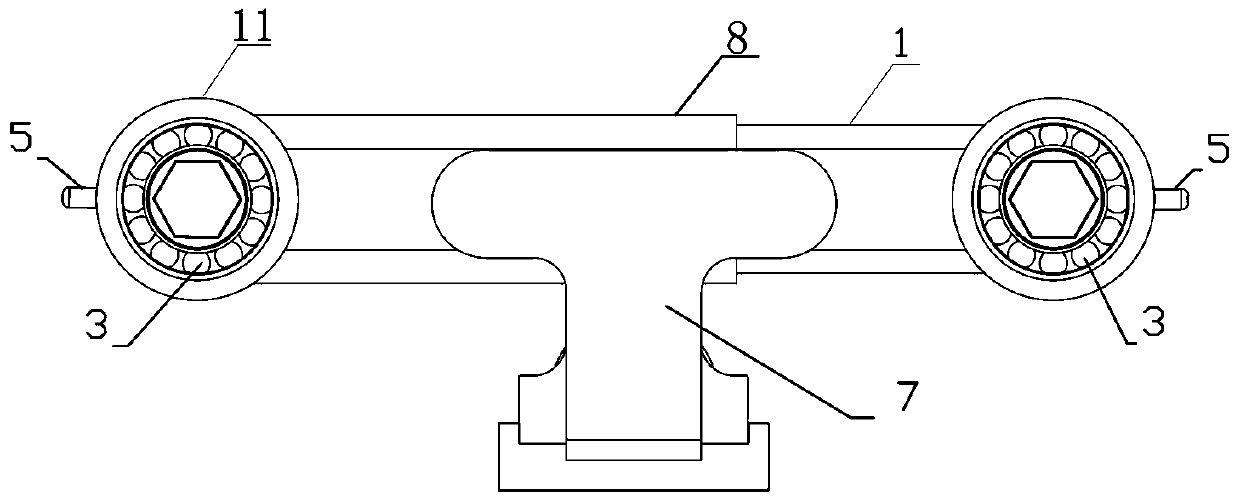

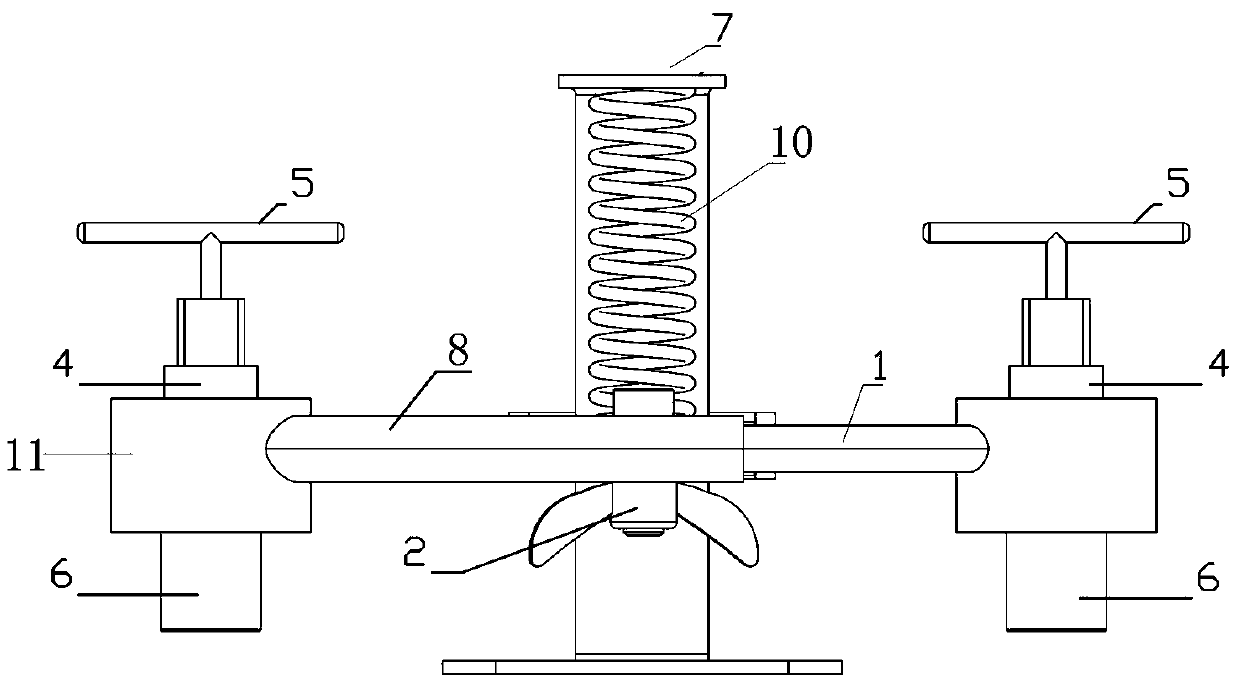

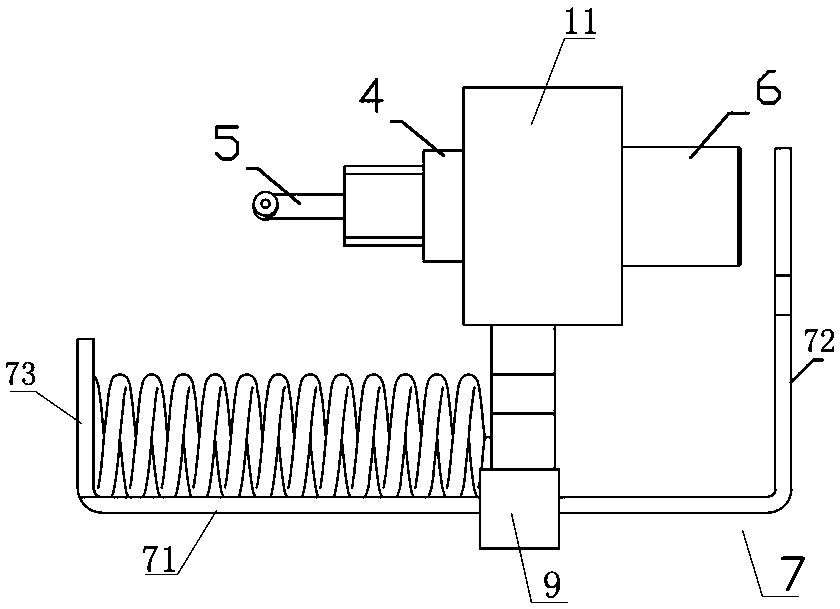

[0043] A gear adjustment tool for a dry-type transformer, including a connecting plate, a bearing 3, a sleeve adapter 4, a T-handle 5, a universal sleeve 6, a spring baffle 7, a baffle slide frame 9, a spring 10, and a ring The right and left sides of the connecting plate are fixedly provided with a ring cylinder 11, the ring cylinder is provided with a bearing 3, the sleeve adapter 4 is fixed in the bearing 3, and the rear end of the sleeve adapter 4 is provided with T-shaped handle 5, the front end of the sleeve adapter 4 is provided with a universal sleeve 6; the lower end of the connecting plate is vertically provided with a baffle slide rack 9, the spring baffle 7 is composed of a sliding bottom plate 71, a clamping plate 72 and a spring fixing plate 73. The clamping plate 72 and the spring fixing plate 73 are respectively vertically arranged at the front and rear...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap