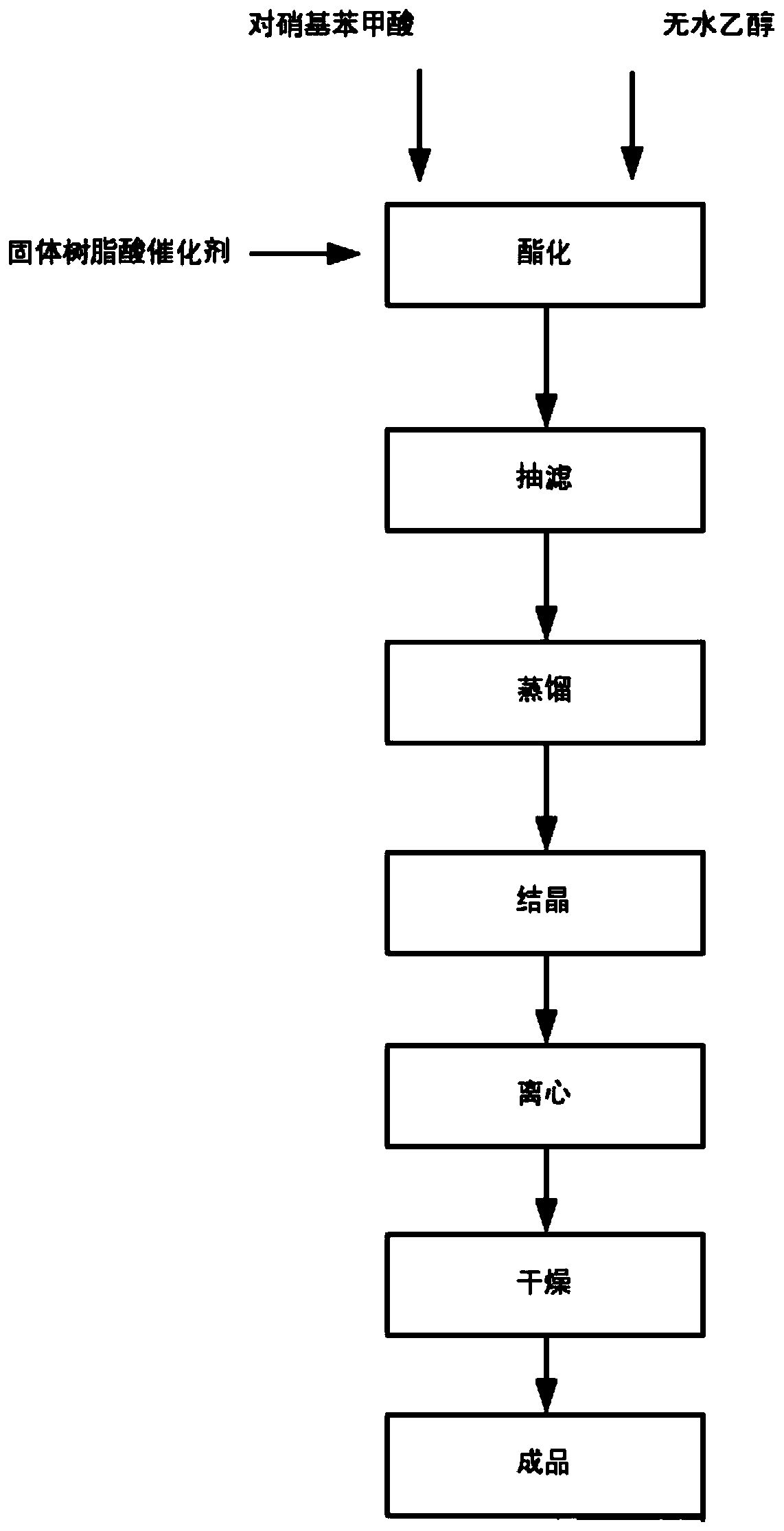

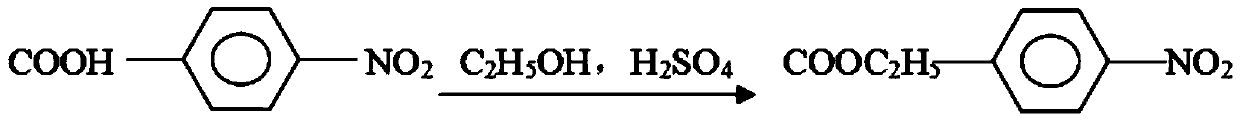

Preparation process of ethyl p-nitrobenzoate

A technology of ethyl nitrobenzoate and p-nitrobenzoic acid, applied in the field of preparation of ethyl p-nitrobenzoate, achieving good application prospects, improving production efficiency, and avoiding complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Get 22.4g p-nitrobenzoic acid and be dissolved in ethanol solution (mass percentage composition of ethanol is 99.9%), be configured into the p-nitrobenzoic acid solution that percentage composition is 4%, put into feed tank circulation, in The sulfonic acid resin catalyst is filled in the fixed-bed catalytic micro-reaction tank, the temperature of the feed tank is set to 70°C, the temperature of the fixed-bed catalytic micro-reaction tank is 80°C, the reaction pressure is 0.4MPa, and the flow rate is 5ml / min. Turn on the liquid phase pump, inject the solution in the feed tank into the fixed bed catalytic micro-reaction tank, and then receive the liquid out. In the continuous reaction, three product samples and one mixed sample were taken and detected by high performance liquid chromatography, and the conversion rate of the reaction was 89.92%.

Embodiment 2

[0043] Get 22.4g p-nitrobenzoic acid and dissolve in ethanol solution (mass percentage composition of ethanol is 99.9%), configure the p-nitrobenzoic acid solution that percentage composition is 4%, put into feed tank and circulate. Fill the sulfonic acid resin catalyst in the fixed-bed catalytic micro-reaction tank, set the temperature of the feed tank to 70°C, the temperature of the fixed-bed catalytic micro-reaction tank to 80°C, the reaction pressure to 0.4MPa, and the flow rate to 10ml / min. Turn on the liquid phase pump, inject the solution into the fixed-bed catalytic micro-reaction tank, and receive the effluent. In the continuous reaction, three product samples and one mixed sample were taken and detected by high-performance liquid chromatography, and the conversion rate of the reaction was 86.55%.

Embodiment 3

[0045] Get 22.4g p-nitrobenzoic acid and dissolve in ethanol solution (mass percentage composition of ethanol is 99.9%), configure the p-nitrobenzoic acid solution that percentage composition is 4%, put into feed tank and circulate. Fill the sulfonic acid resin catalyst in the fixed-bed catalytic micro-reaction tank, set the temperature of the feed tank to 70°C, the temperature of the fixed-bed catalytic micro-reaction tank to 80°C, the reaction pressure to 0.4MPa, and the flow rate to 20ml / min. Turn on the liquid phase pump, inject the solution into the fixed-bed catalytic micro-reaction tank, and receive the effluent. In the continuous reaction, three product samples and one mixed sample were taken and detected by high performance liquid chromatography, and the conversion rate of the reaction was 81.41%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com