An energy-saving and environment-friendly electroplating workpiece painting device

An energy-saving, environmentally friendly, and workpiece-friendly technology, applied in the direction of spraying devices, can solve problems such as injury, time-consuming and labor-intensive human skin, and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

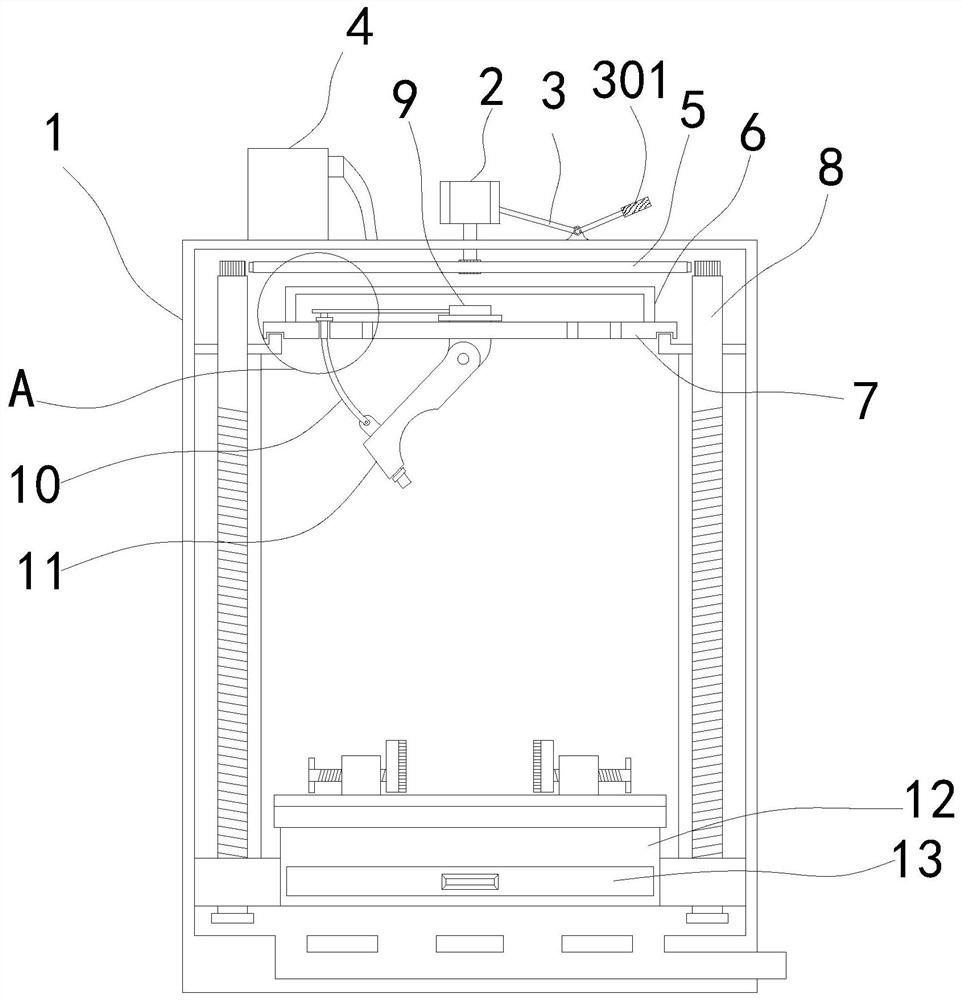

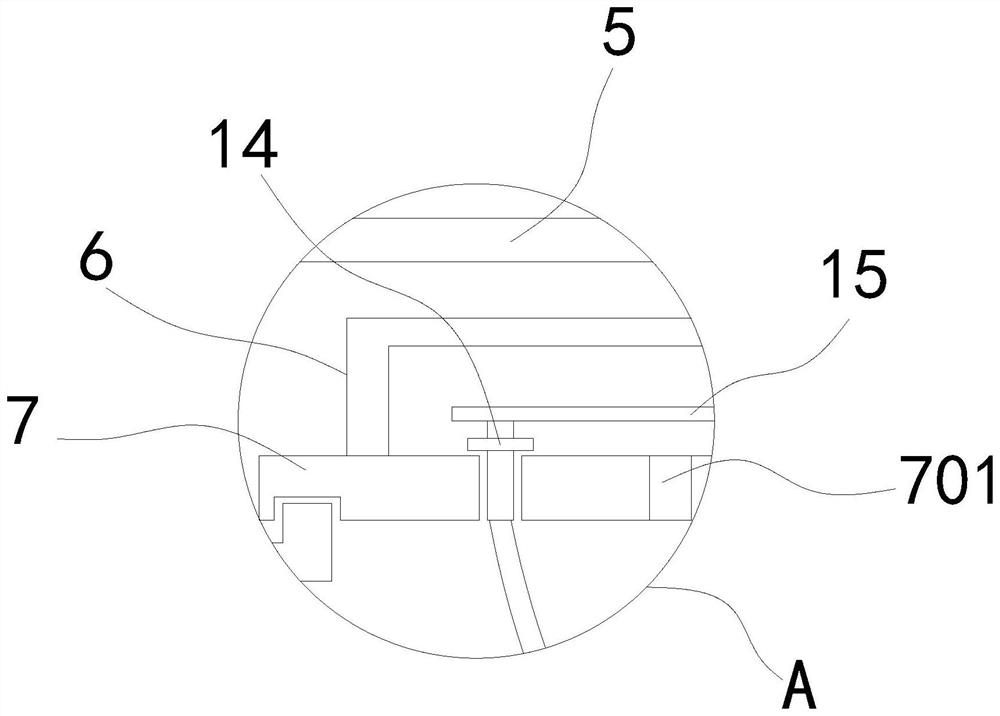

[0027] see Figures 1 to 9 , an energy-saving and environment-friendly electroplating workpiece painting device planar structure schematic diagram and three-dimensional structural schematic diagram.

[0028] An energy-saving and environment-friendly paint spraying device for electroplating workpieces, comprising a device main body 1 and a mold 2. The mold 2 is movably installed inside the device main body 1, and a first motor 5 is fixedly installed at the lower end of the device main body 1, and the upper end of the first motor 5 is connected with a negative Swash plate 4, second motor 6 is fixedly installed on the right side of first motor 5, the upper end of second motor 6 is fixedly connected with liquid oil swash plate 3, and the bottom of liquid oil swash plate swash plate is fixedly connected with heating wire 8.

[0029] In a specific implementation, the lower end of the motor 2 is movably connected to the control part 101, and the upper end of the control part 101 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com