Method for modifying toughness of epoxy resin through toughening agent

A technology of epoxy resin and toughening agent, which is applied in the field of toughening agent modified epoxy resin toughness, can solve the problems of brittleness of cured material, poor impact resistance, and restricted application, so as to increase bonding performance, meet process requirements, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

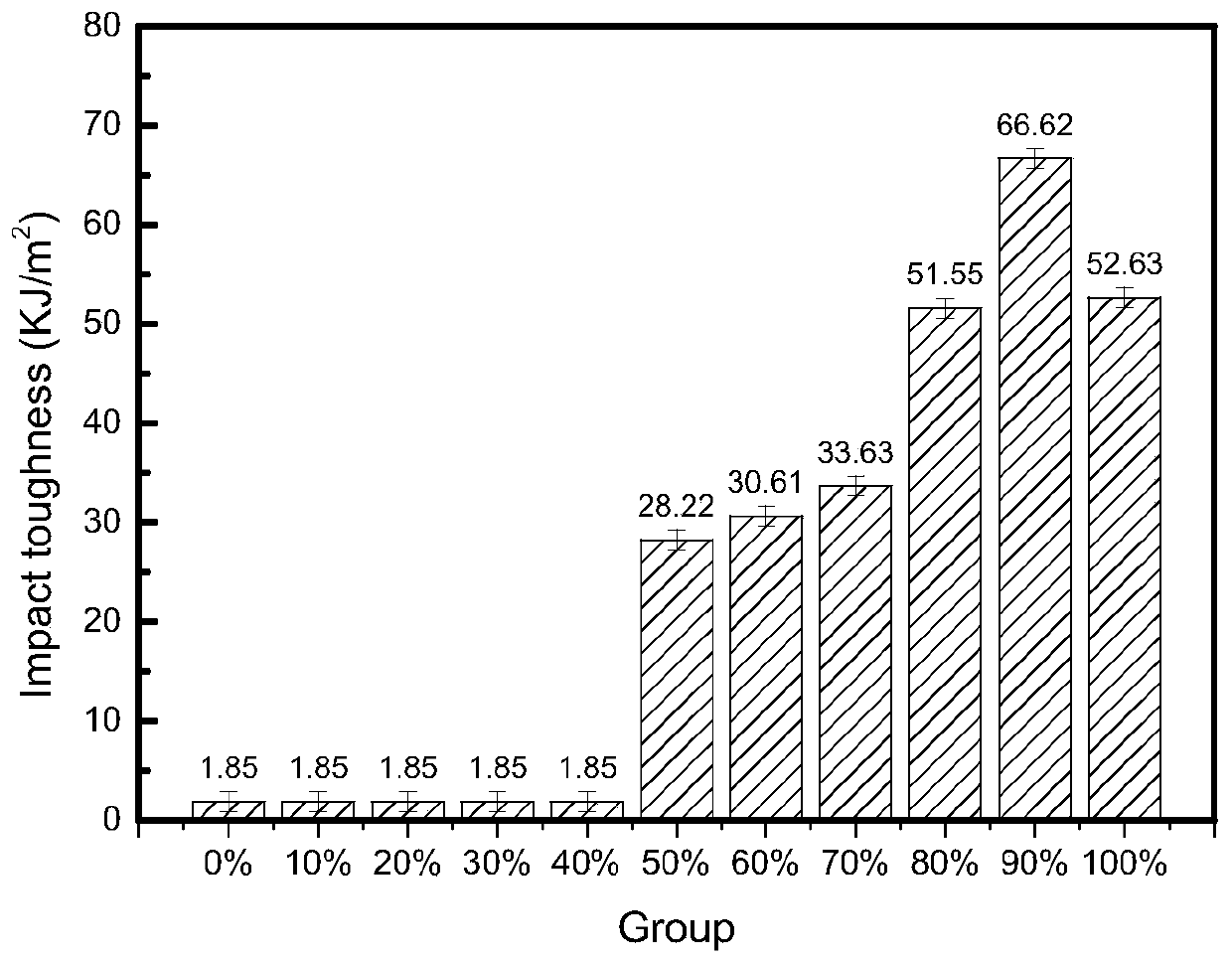

[0079] Polycaprolactone diol modified high temperature curing system:

[0080] Put epoxy resin E51, polycaprolactone diol, modified methyltetrahydrophthalic anhydride and other raw materials with 2-methylimidazole additives in proportion in an oven at 50°C for 60 minutes, and according to the toughening agent polycaprolactone di The mass ratio of alcohol / epoxy resin E51 is 0 / 100, 10 / 100, 20 / 100, 30 / 100, 40 / 100, 50 / 100, 60 / 100, 70 / 100, 80 / 100, 90 / 100, Mix them in a ratio of 100 / 100, mark them as groups 2 to 11, stir well and place them in an oven at 50°C for 10 minutes to keep warm. Then 88 parts of modified methyltetrahydrophthalic anhydride were added to each component and mixed. At the same time, a group of control groups without toughening agent was set according to the original ratio as the first group. They were fully stirred evenly and placed in a defoamer Foaming, pour the mixed resin into the mold that meets the requirements of the GB / T2567-2008 resin casting body tes...

Embodiment 2

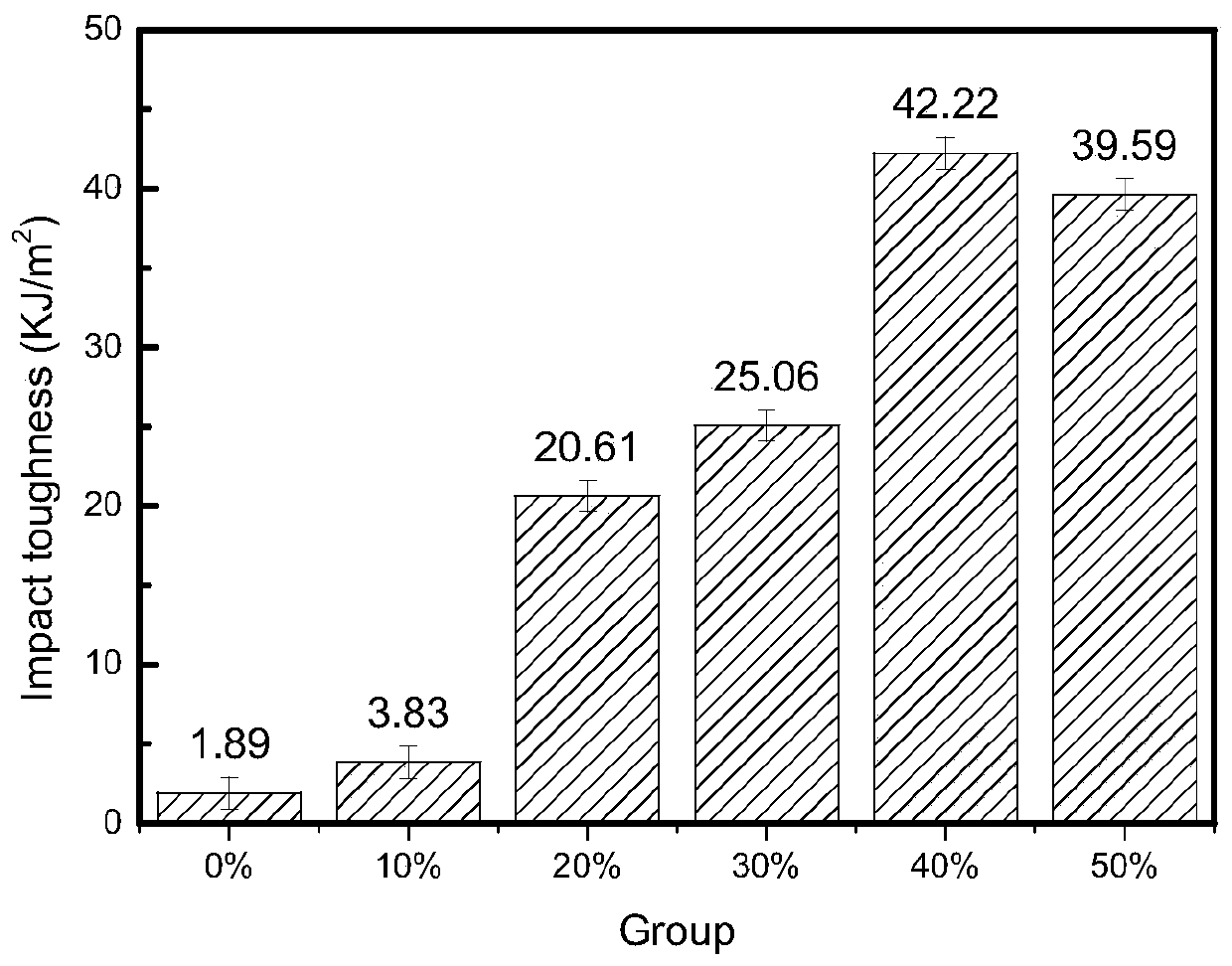

[0082] Polycaprolactone diol modified low temperature curing system:

[0083] Put epoxy resin E51, polycaprolactone diol and other raw materials in an oven at 50°C for 60 minutes, according to polycaprolactone diol / epoxy resin E51=10 / 100, 20 / 100, 30 / 100, 40 / 100 , mixed in a 50 / 100 ratio, marked as 2-6 groups, stirred well, placed in a 50°C oven for 10 minutes, then took out the mixed samples of each group, measured the temperature with a thermometer and added 30 parts to each group Modified polyamine curing agent. At the same time, set a group of control group without adding toughening agent according to the original ratio as the first group. After fully stirring, put it into the defoaming machine for defoaming treatment. Then pour the mixed resin into a mold that meets the requirements of the GB / T 2567-2008 resin casting body test standard, and cure completely according to the curing system at 40°C for 600min—80°C for 120min. The impact toughness of each cured resin cast bod...

Embodiment 3

[0085] Determination of curing system and curing degree of polycaprolactone diol modified high temperature curing system:

[0086] Put epoxy resin E51, polycaprolactone diol, modified high-temperature curing agent methyltetrahydrophthalic anhydride and other raw materials added in proportion to 2-methylimidazole additives in an oven at 50°C for 60 minutes, and take 90 parts of toughening agent Add polycaprolactone diol to 100 parts of epoxy resin E51, stir well and put it in an oven for 10 minutes, then take two parts of 88 parts of modified methyltetrahydrophthalic anhydride and add them to the mixed resin solution and 100 parts of epoxy resin respectively Stir evenly in E51, put it into a defoaming machine for defoaming treatment, place it at room temperature for a period of time, mark the formula without adding toughening agent as group B, and the formula with adding toughening agent as group A, wait until the temperature After reaching room temperature, DSC analysis was ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com