Water-repellent coating composition and water-repellent coating substrate coated with same

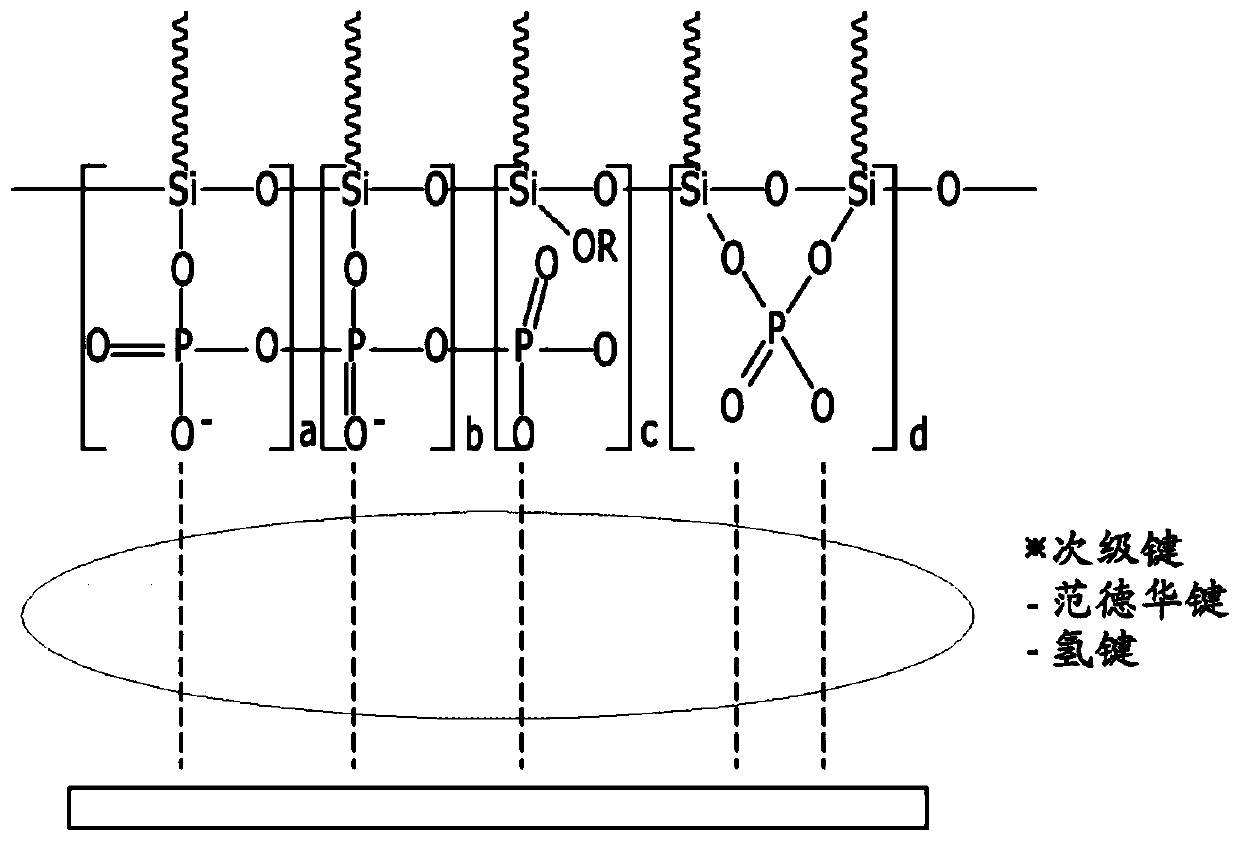

A waterproof coating and waterproof coating technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as low adhesion of substrates, and achieve low processing costs and excellent durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0062] 0.2 g of fluorinated silane (DAIKIN, OPTOOL UD509), 50 g of fluorinated solvent (3M, Novec-7200), 2 g of ethanol (Burdick & Jackson) and 0.05 g of phosphoric acid (Shinetsu, D-220) were mixed and stirred for 10 minutes , to prepare a waterproof coating composition.

Embodiment 1

[0066] The waterproof coating composition of the preparation example was flow-coated on a PET (SKC, 250 μm) substrate, and then thermally cured in an oven at 85° C. for 30 minutes to form a waterproof coating.

Embodiment 2

[0068] A waterproof coating was formed in the same manner as in Example 1 except that LCD glass (100 mm×100 mm, thickness 0.5T (500 μm)) was used as a base material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com