Underground drill rig supporting frame

A technology of tunnel drilling rig and support frame, which is applied in the direction of drilling equipment, earthwork drilling and production, support devices, etc., which can solve the problems of inconvenient adjustment of drilling angle, time-consuming and laborious, etc., and achieve the effect of ingenious structure, convenient use and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example 1:

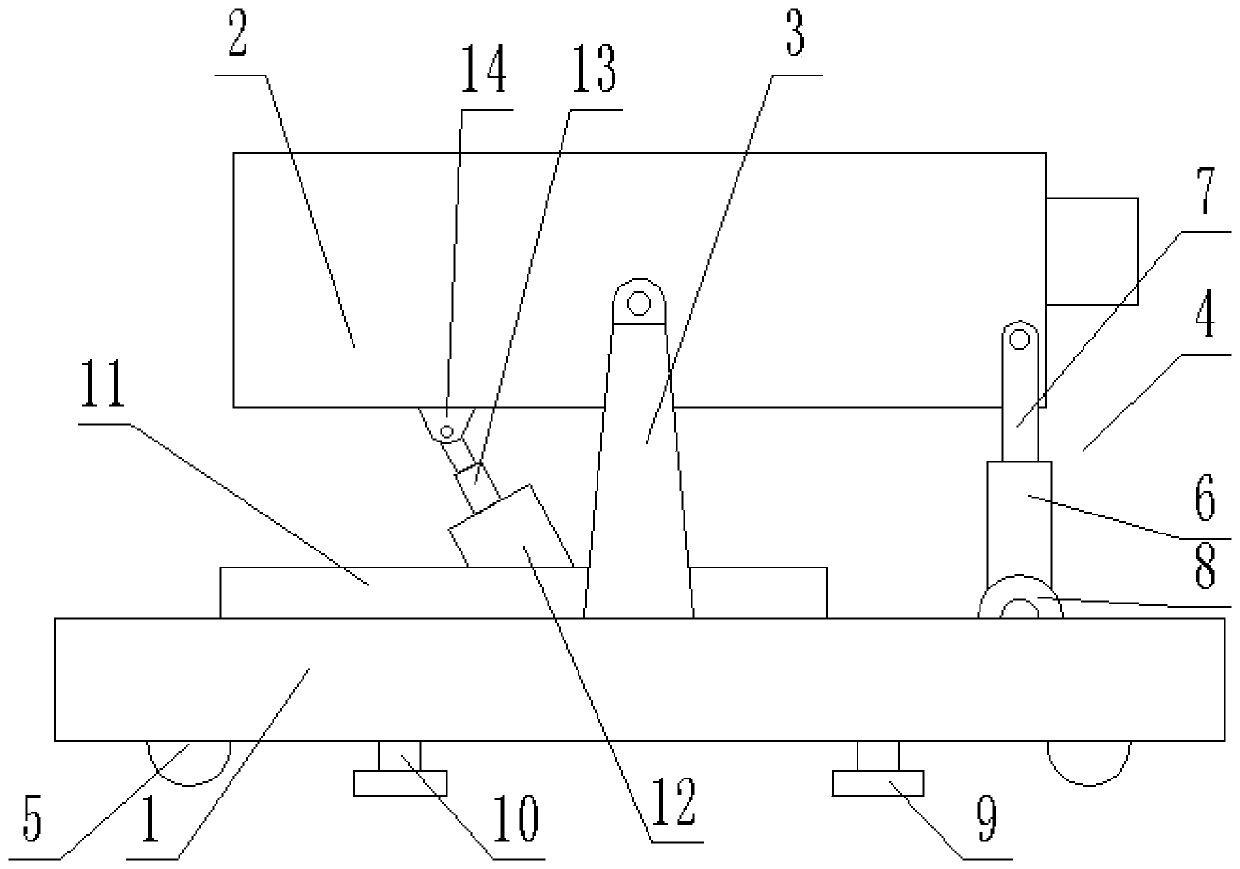

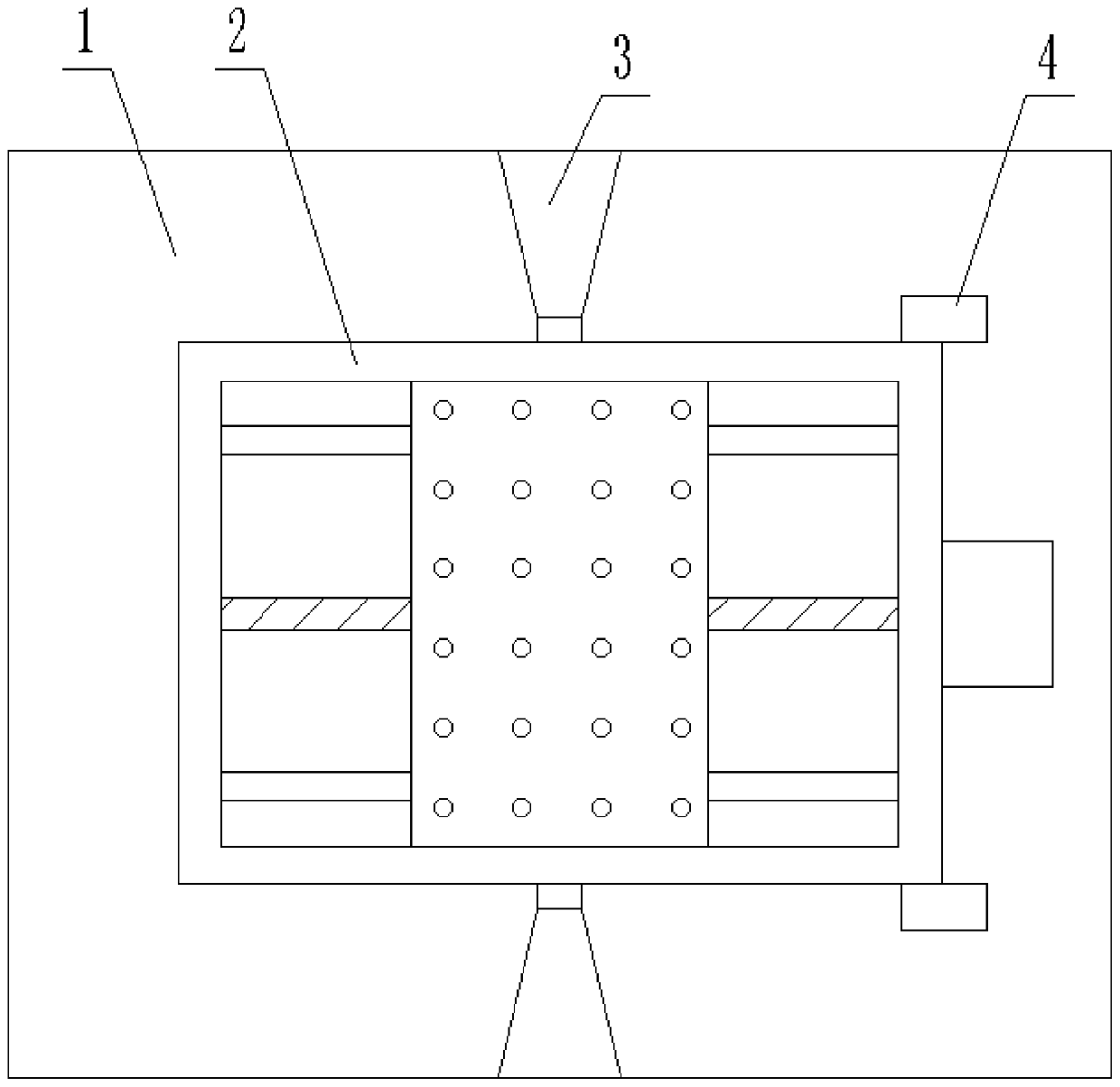

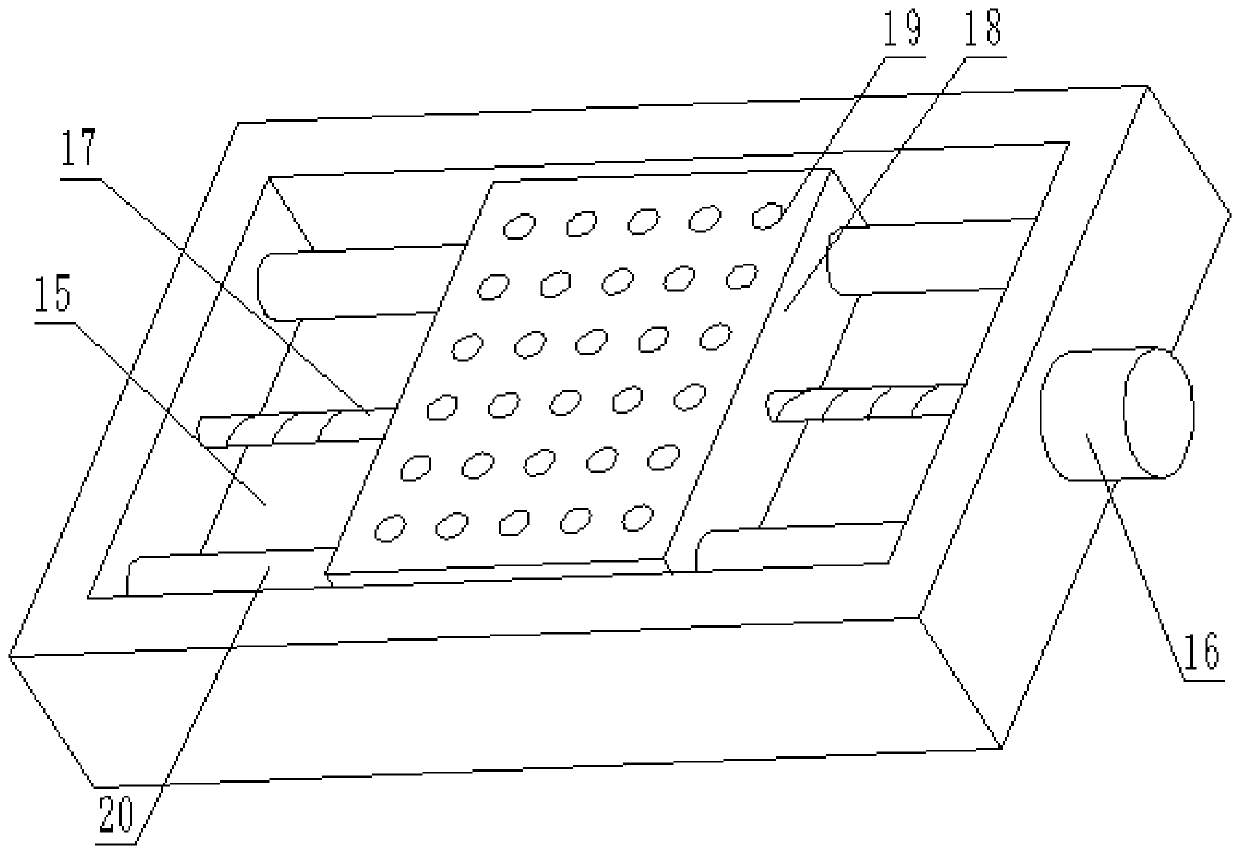

[0020] See Figure 1-3 , A tunnel drilling rig support frame, including a mobile platform 1 and an installation platform 2. The installation platform 2 is located above the mobile platform 1, and there are support rods 3 at the center of both sides of the installation platform 2. The support rods 3 are inclined at an angle of 65° to the horizontal , The lower end of the support rod 3 is welded to the top surface of the mobile platform 1, and the upper end of the support rod 3 is rotatably connected to the mounting platform 2. The mounting platform 2 is used to install drilling equipment, and the bottom surface of the mobile platform 1 is provided with multiple rollers 5 for the transfer of the drilling rig Positioning, specifically, the mounting platform 2 has a square movable cavity 15 on the top surface, two parallel sliding rods 20 are provided in the movable cavity 15, and a sliding table 18 slidably connected to the sliding rod 20 is sleeved, The sliding...

Example Embodiment

[0023] Example 2:

[0024] On the basis of embodiment 1, a plurality of screw holes 19 are opened on the top surface of the sliding table 18, and the plurality of screw holes 19 are distributed in a matrix. The arrangement of the plurality of screw holes 19 greatly improves the adaptability of the device , It can be fixedly installed on drilling rigs of different specifications to adapt to different drilling tasks.

Example Embodiment

[0025] Example 3:

[0026] On the basis of embodiment 1, the bottom of the mobile platform 1 is provided with a plurality of lifting screws 10 that are rotatably connected with them, and a rubber pad 9 is fixed at the bottom of the lifting screw 10. When moving, the lifting screw 10 is rotated to make it rise , It is convenient to transfer. After the transfer is completed, the lifting screw 10 is rotated in reverse to lower it, and the rubber pad 9 is attached to the ground to improve the overall stability of the device when the rig is working.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap