Packaging rolled film automatic manufacturing equipment and method thereof

A rolling film and automatic technology, applied in packaging, cardboard items, etc., can solve problems such as low yield, low efficiency, and complicated process steps, and achieve the effect of improving production efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

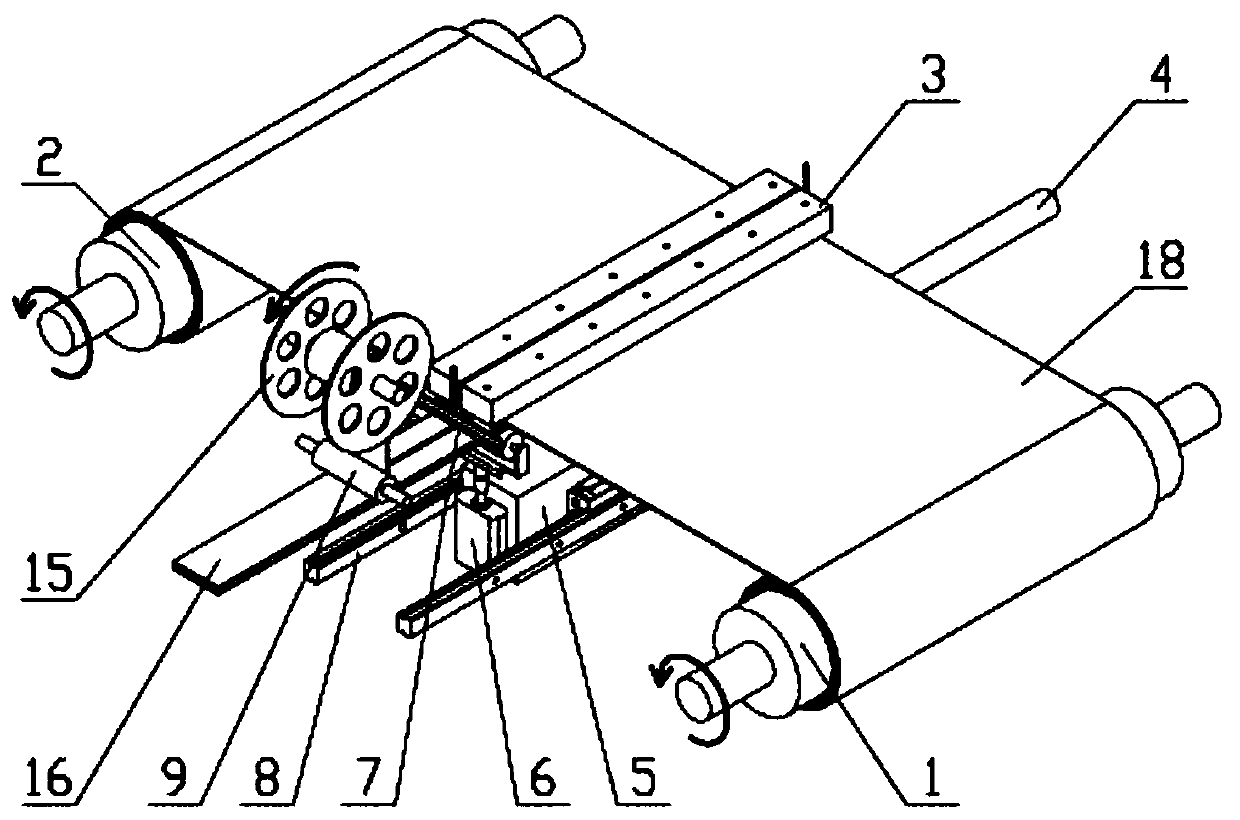

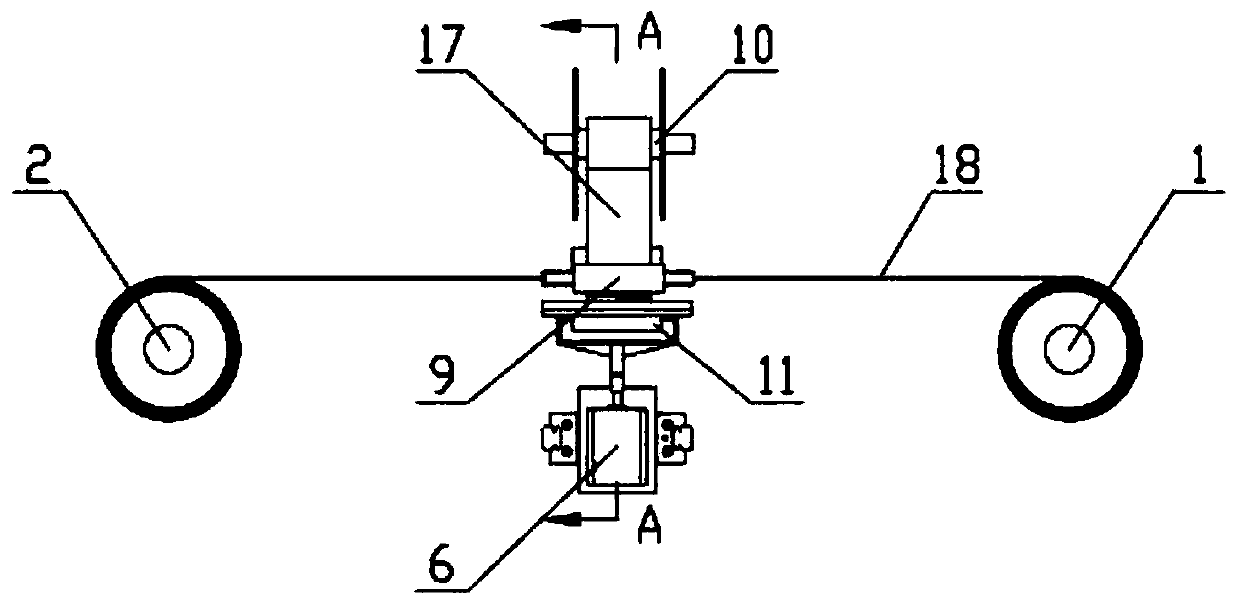

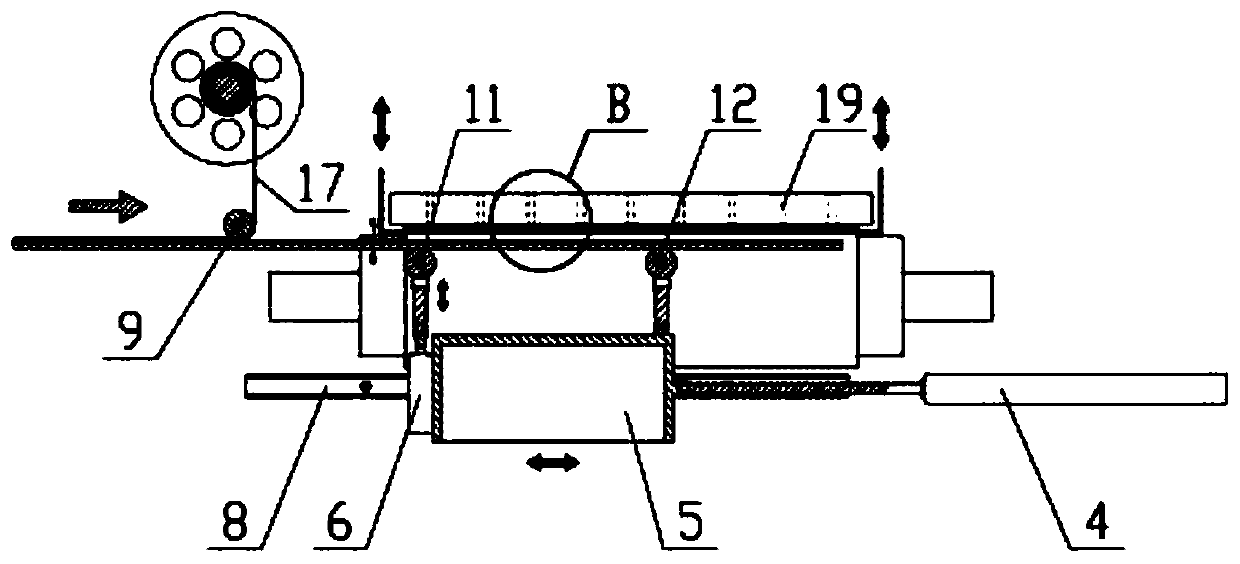

[0029] Such as Figures 1 to 6 As shown, a kind of automatic package roll film production equipment, including film release roller 1, film take-up roller 2, tape conveying device, release film take-up roll 10, tape cutting knife 7, tape pressure roller 11 and roll film cutting Knife13. The film release roller 1 conveys the roll film 18 to the film roll 2 along the first direction, and the tape conveying device conveys the double-sided "U-shaped" adhesive tape 16 to the bottom of the roll film 18 along the second direction, the release film winding roller 10 and the tape Cutter 7 is all arranged on the same side of roll film, and release film take-up roller 10 is positioned at the top of adhesive tape conveying path, is used for rewinding the release film 17 that is torn off from double-sided " U-shaped " adhesive tape 16; The cutting knife 7 is moved along the third direction and is arranged in front of the separation between the release film 17 and the double-sided "U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com