Multimode Clutch

A clutch and control ring technology, applied to clutches, one-way clutches, mechanical equipment, etc., can solve the problems of inner ring slipping, low locking torque, multi-mode clutch failure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

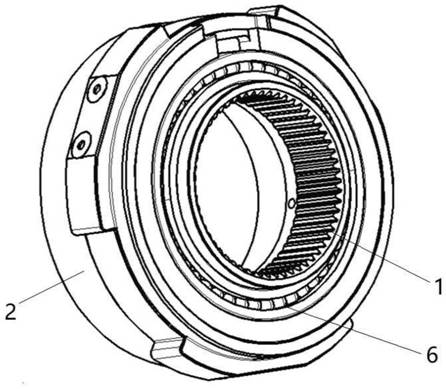

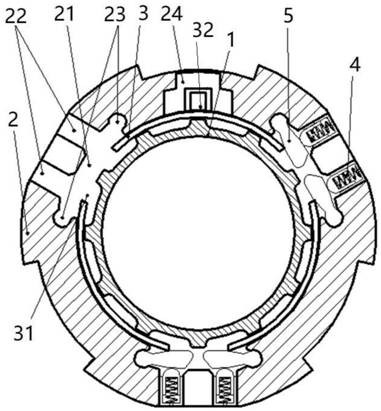

[0016] A multi-mode clutch such as figure 1 , figure 2 , as shown in Figure 3(a) and Figure 3(b), including the inner ring 1, the outer ring 2 and the control ring 3, the inner ring 1, the outer ring 2 and the control ring 3 are all cylindrical sleeve structures, the inner ring 1 There are several uniformly distributed rectangular spline teeth 11 on the outer surface, the inner surface of the inner ring 1 and the outer surface of the outer ring 2 are all spline structures, and the inner surface of the outer ring 2 is provided with three uniformly distributed spline teeth. Avoidance groove 21, the bottom of avoidance groove 21 is provided with two radial through-holes 22, is provided with the locating seat 4 that spring is installed in the radial through-hole 22 and locating seat 4 can radially expand and contract, and avoiding groove 21 is parallel to the axis. There are axial through grooves 23 of symmetrical cylindrical structure on both sides of the direction. The axial t...

Embodiment 2

[0019] A multi-mode clutch, its structure is similar to that of the multi-mode clutch in Embodiment 1, the difference is that the number of escape grooves on the outer ring is four, the number of windows on the control ring is four, and the number of windows on the outer ring is four. A ball bearing is arranged at one end between the ring and the inner ring, and the ball bearing is opposite to the end face of the control ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com