Plate drilling and surface defect detection device and application method

A defect detection and sheet metal technology, applied in measuring devices, optical testing of flaws/defects, analysis of materials, etc., can solve problems such as low efficiency, labor-intensive, easy to miss detection, etc., to achieve reasonable settings, reduce wastage, reduce Effects of external light interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

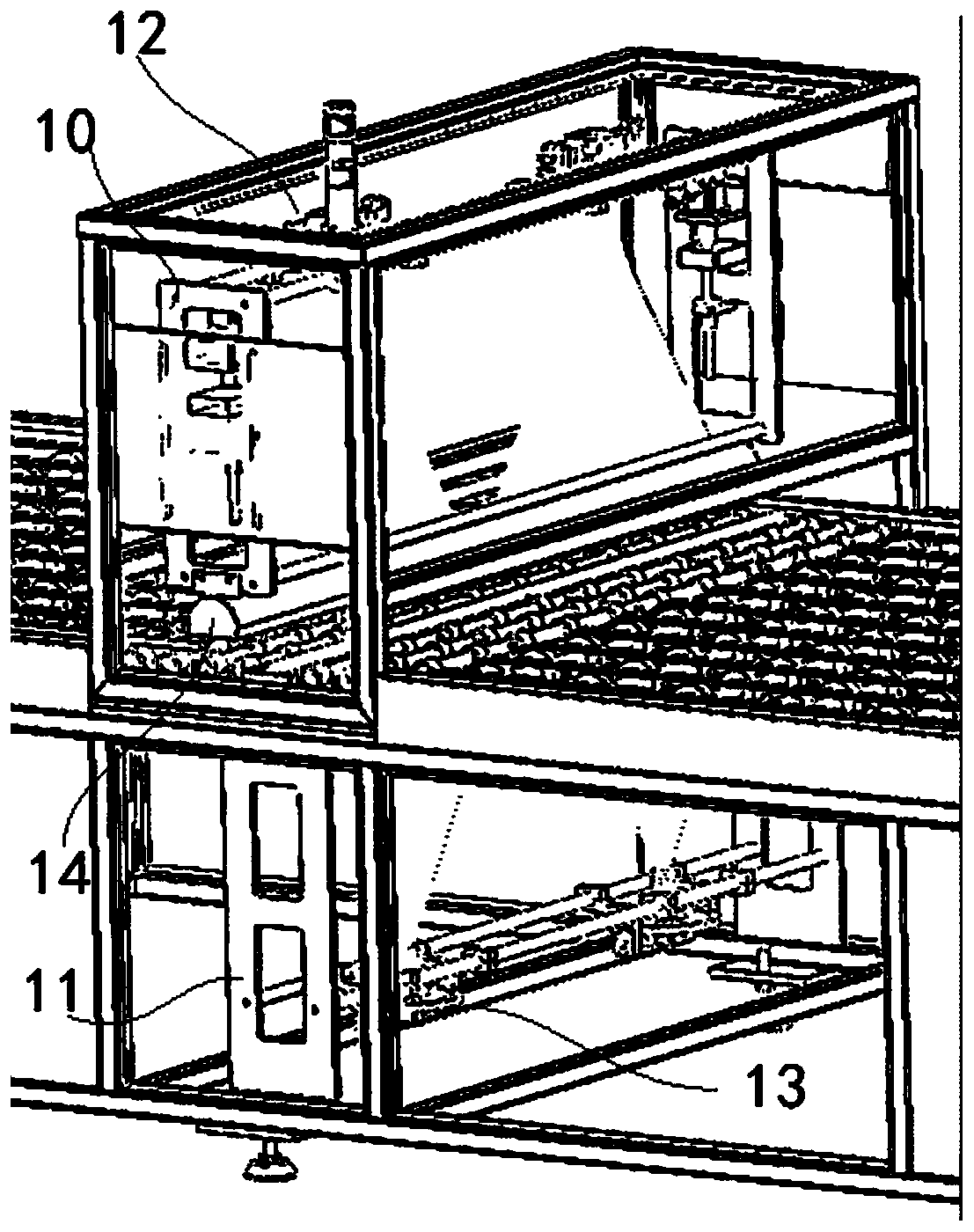

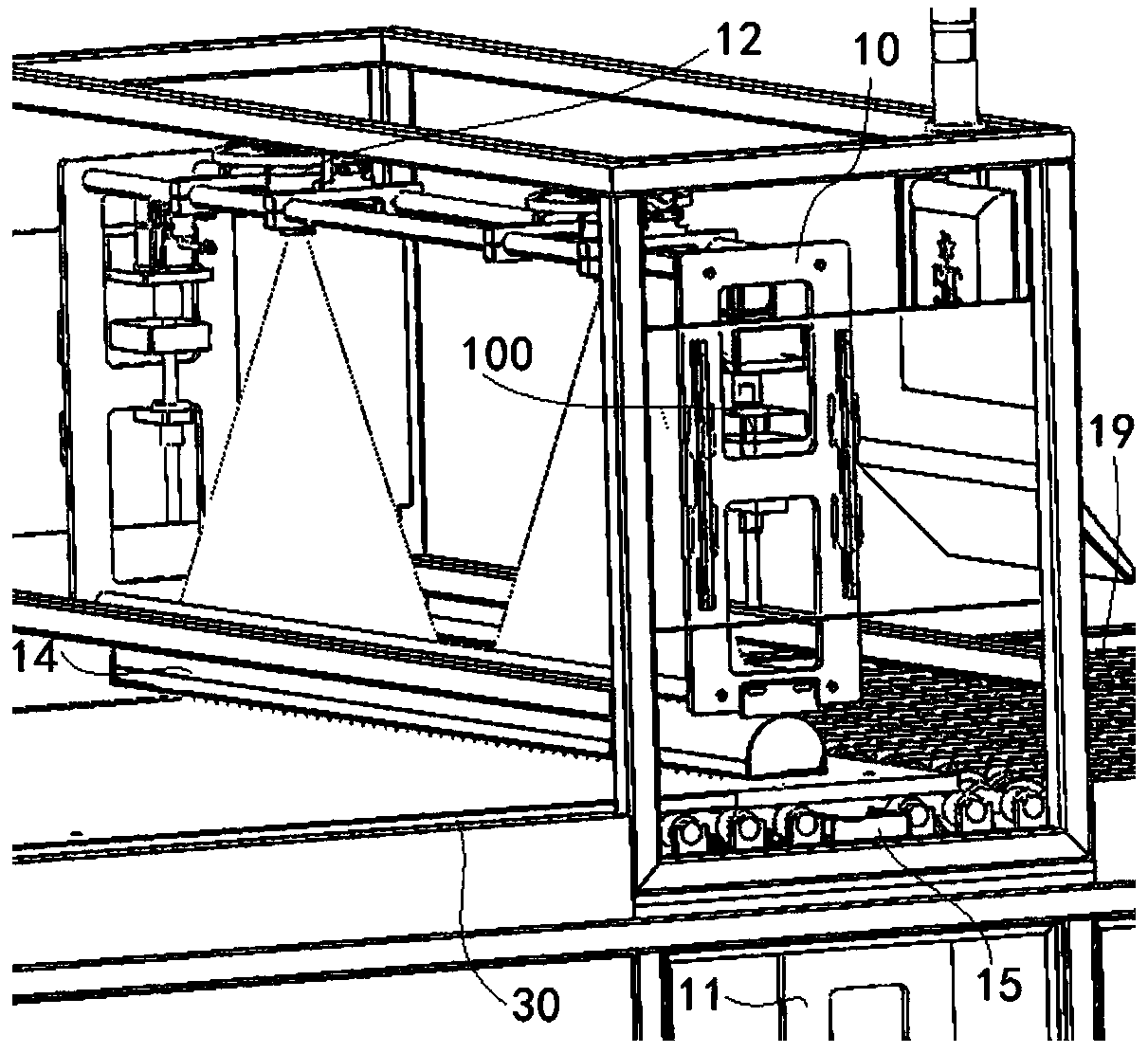

[0047] according to Figure 5 As shown, the plate undergoing quality inspection can also be called plate 30, which has a number of drill holes 31. Of course, occasionally there may be physical defects on the front and back of some plates 30, such as chipping and scratches. Etc., also have the drilling 31 of sheet material 30 to possibly have defects such as size fallacy.

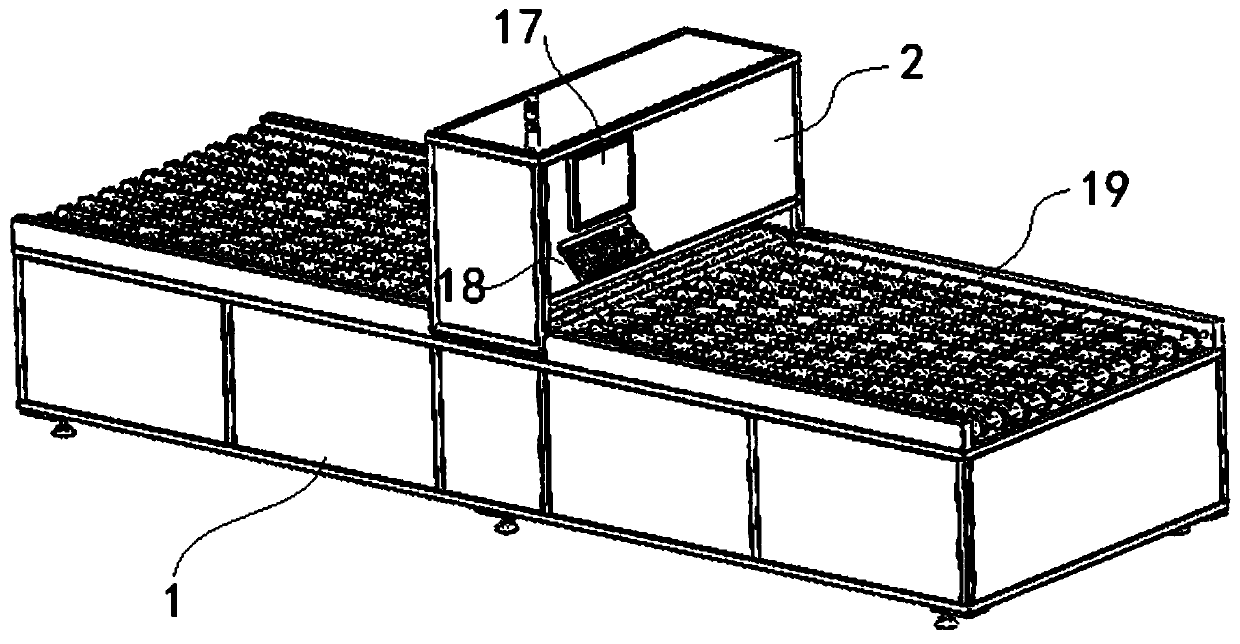

[0048] Such as Figure 1-8 The plate drilling 31 and the surface defect detection device according to the present invention are shown, including but not limited to: frame 1, scanning detection module, position switch, lighting module and computer.

[0049] The frame 1 is provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap