A kind of LED display panel, its preparation method and display device

A display panel and LED chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as uneven exposure, and achieve the effect of improving the uniformity of light output and ensuring consistent light output efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

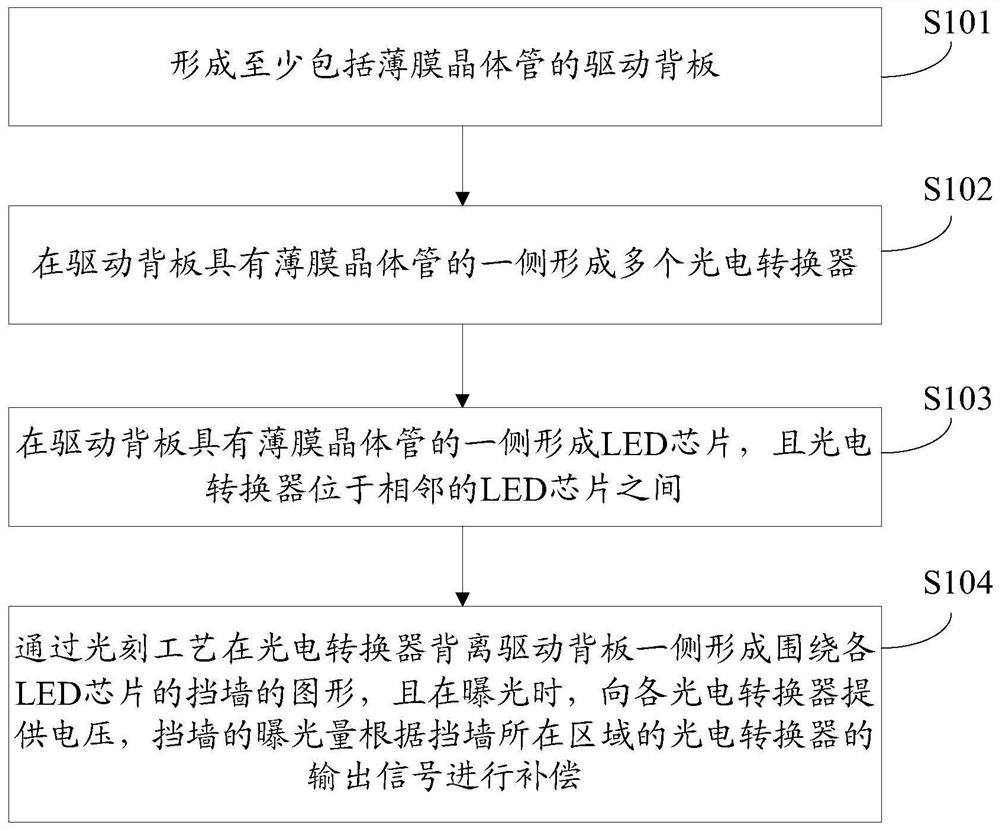

[0038] A kind of preparation method of LED display panel provided by the embodiment of the present invention, such as figure 1 shown, including:

[0039] S101, forming a driving backplane including at least thin film transistors;

[0040] S102, forming a plurality of photoelectric converters on the side of the driving backplane with thin film transistors;

[0041] S103, forming LED chips on the side of the driving backplane with thin film transistors, and the photoelectric converters are located between adjacent LED chips;

[0042] S104. Form the pattern of the barrier wall surrounding each LED chip on the side of the photoelectric converter away from the driving backplane through the photolithography process, and provide voltage to each photoelectric converter during exposure, and the exposure amount of the barrier wall depends on the area where the barrier wall is located. The output signal of the photoelectric converter is compensated; the closer to the surface of the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com