A load verification method for concrete batching scale

A technology for batching scales and concrete, applied in batching weighing instruments, chemical instruments and methods, mixing operation control, etc., can solve the problems that standard methods are difficult to verify the full scale, cost a lot of manpower and material resources, and cannot find materials, etc., to achieve Considerable social and economic benefits, improved efficiency, and accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A method for verifying the load of a concrete batching scale, comprising the following steps:

[0035] 1) Equipment installation, the specific steps are:

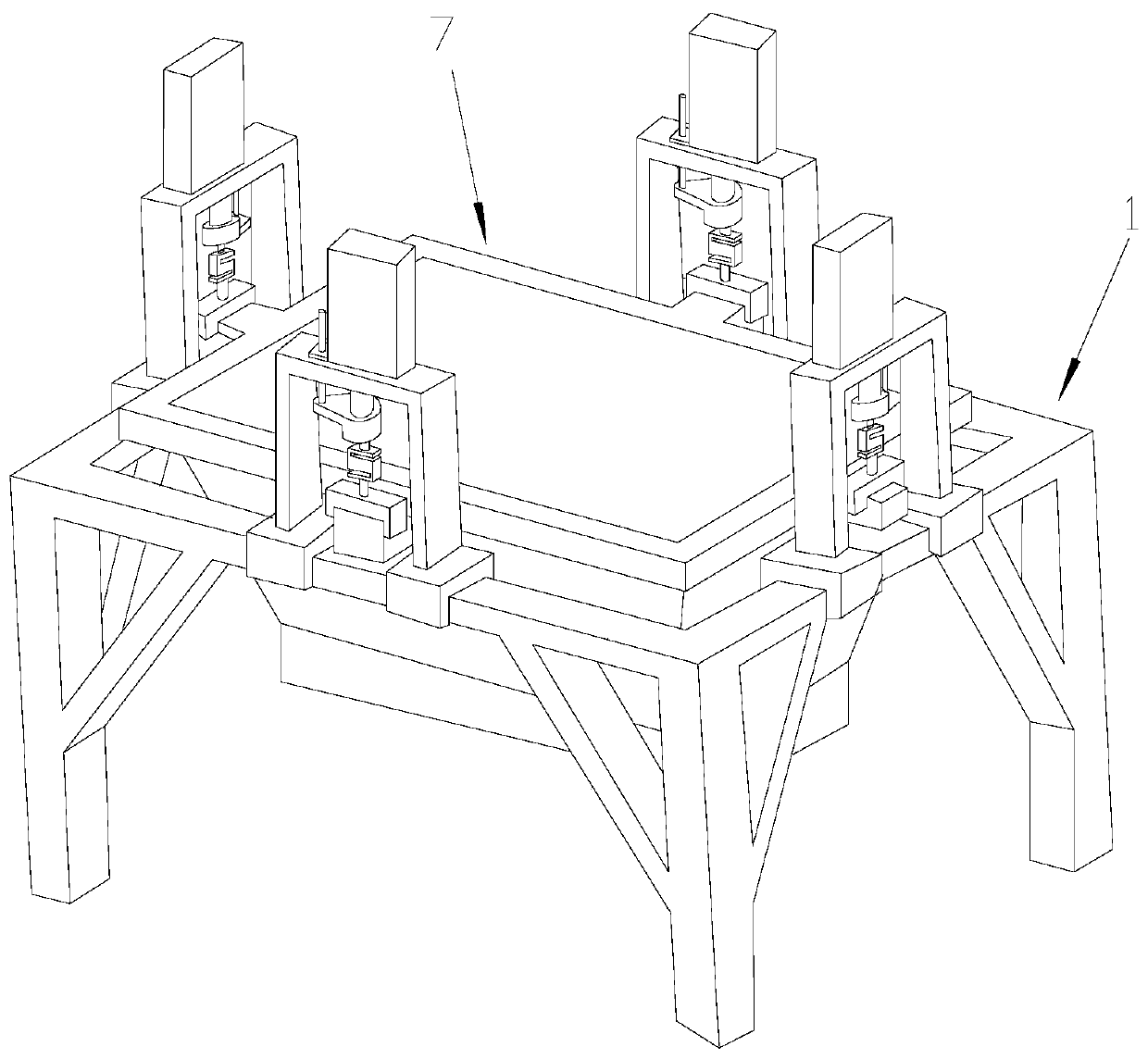

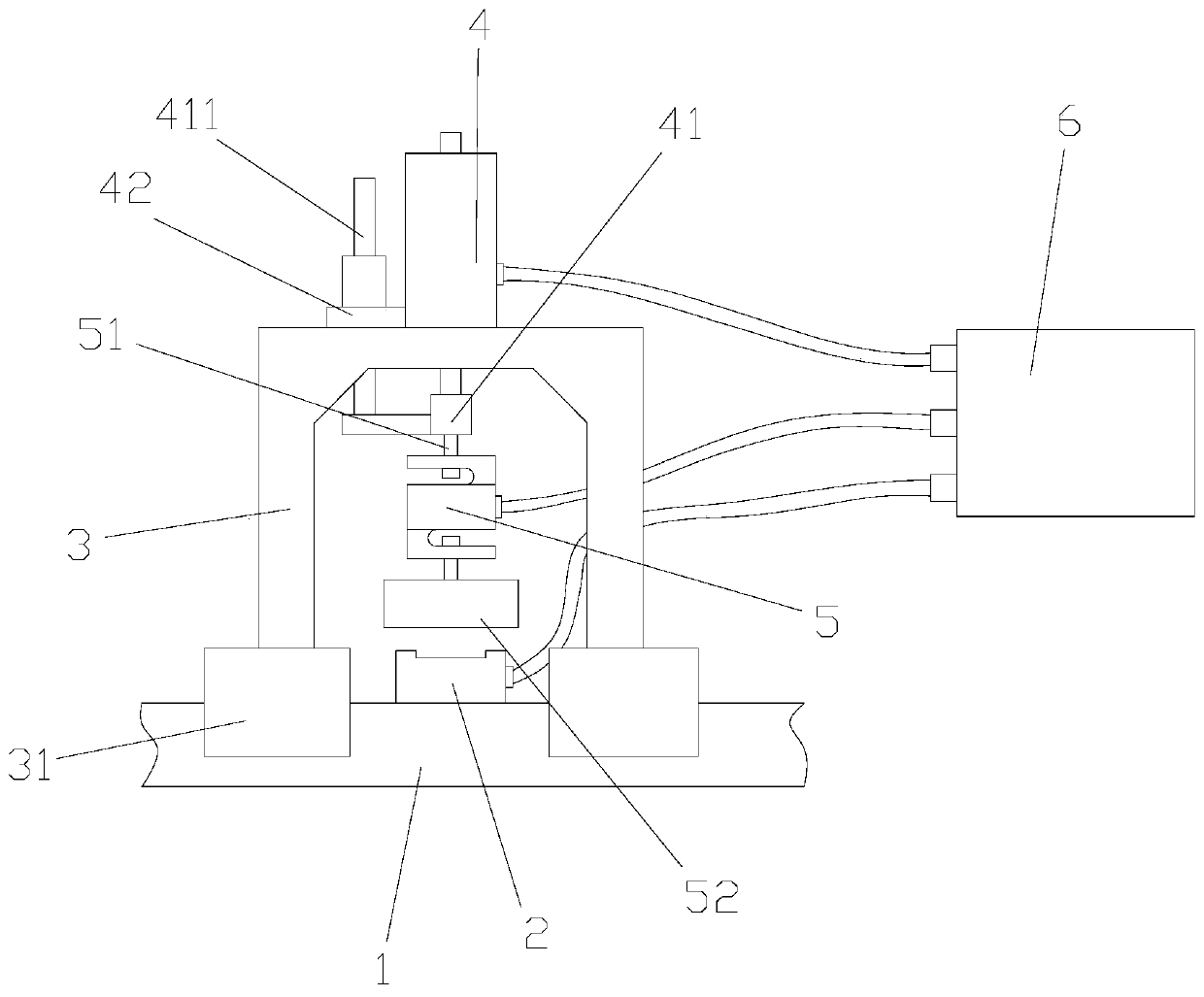

[0036] A. Working sensors 2 are installed in the middle of the four fixed rods on the rectangular batching scale support 1, and every two working sensors 2 are set correspondingly;

[0037] B. Place the weighing hopper 7 in the bracket 1 of the batching scale, and the fixing ears in the middle of the four sides of the weighing hopper 7 correspond to the working sensor 2, and the fixing ears are located above the working sensor 2 and squeeze the working sensor 2;

[0038] C. Install the verification device on the top of the working sensor 2, and fix it with the batching scale support 1 through the load support frame 3, and then the fixed block 52 at the lower end of the standard sensor 5 in the batching scale bracket 1 is clamped with the fixed ear of the weighing hopper 7 Fixed to achieve accurate support fulcrum, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com