A kind of preparation method of metal silver shell composite phase change capsule with high thermal conductivity

A composite phase transition and metallic silver technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of thermal conductivity restriction, reduced heat storage performance, limited strengthening effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

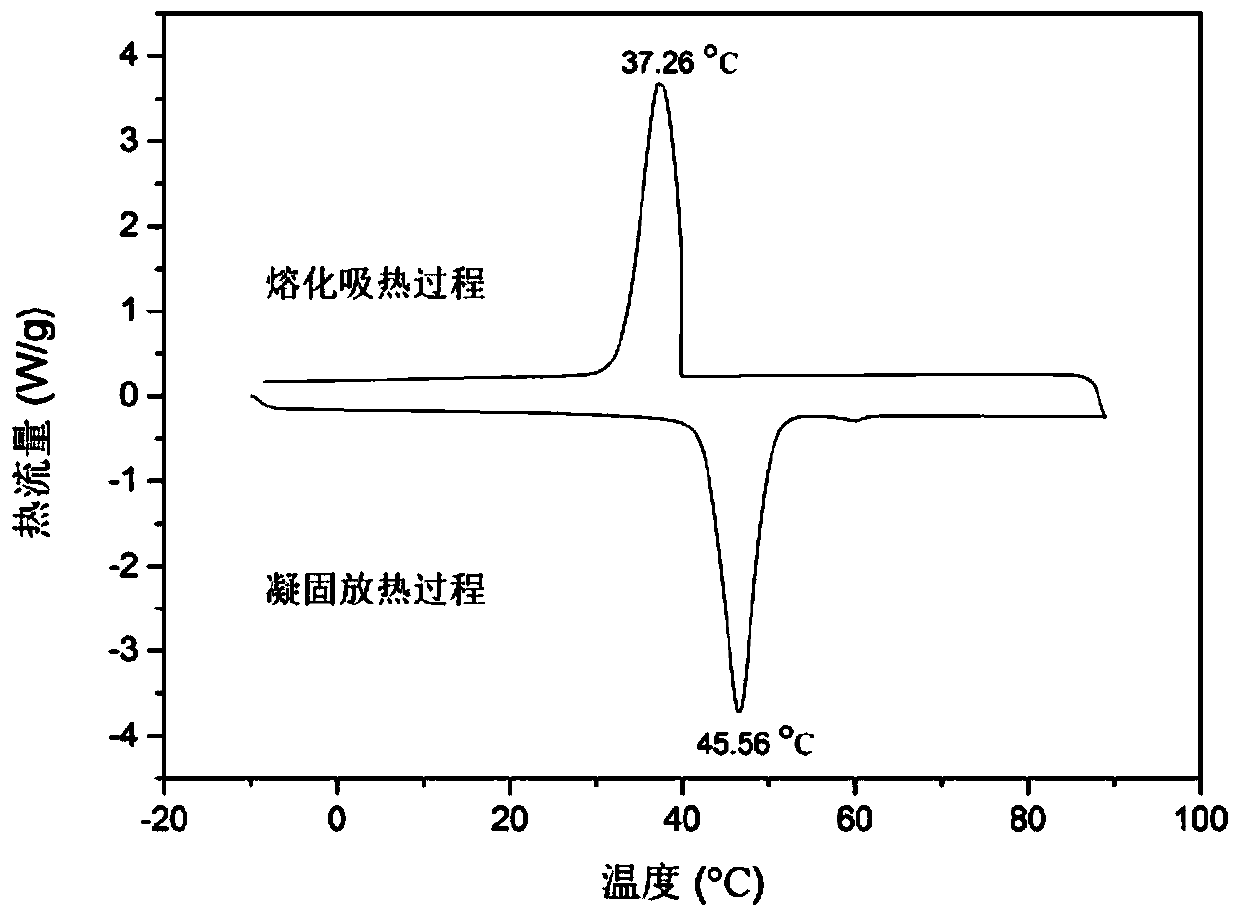

[0031] A method for preparing metal silver shell composite phase-change capsules using lauric acid as a phase-change material, comprising the following steps:

[0032] (1) Preparation of lauric acid emulsion

[0033] (1-1) Select a lauric acid phase change material with a phase transition temperature of 44°C;

[0034] (1-2) choose cetyltrimethylammonium bromide as surfactant;

[0035] (1-3) Add 4g of lauric acid and 0.04g of surfactant to 100ml of deionized water, heat in a water bath at 60°C until the lauric acid melts, and then stir at 800r / min for 1 hour to form a lauric acid emulsion;

[0036] (2) Preparation of phase change emulsion containing silver bromide

[0037] (2-1) Potassium bromide solution with a concentration of 10ml of 100mMol / L and silver nitrate solution of 90mMol / L with a concentration of 10ml are successively poured into the lauric acid emulsion prepared in step (1). Stir at high speed for 30 minutes;

[0038] (2-2) Stop heating and reduce the stirring...

Embodiment 2

[0047] A preparation method for preparing metal-silver shell composite phase-change capsules using palmitic acid as a phase-change material comprises the following steps:

[0048] (1) Preparation of palmitic acid emulsion

[0049] (1-1) Select a palmitic acid phase change material with a phase transition temperature of 63°C;

[0050] (1-2) choose cetyltrimethylammonium bromide as surfactant;

[0051] (1-3) Add 4g of palmitic acid and 0.04g of surfactant to 100ml of deionized water, heat in a 75°C water bath until the palmitic acid melts, and then stir at 800r / min for 1 hour to form a palmitic acid emulsion;

[0052] (2) Preparation of phase change emulsion containing silver bromide

[0053] (2-1) Pour 10ml of potassium bromide solution with a concentration of 100mMol / L and 10ml of silver nitrate solution with a concentration of 90mMol / L into the palmitic acid emulsion prepared in step (1), and continue to process at 600r / min at 60°C Stir at high speed for 20 minutes;

[00...

Embodiment 3

[0062] A preparation method for preparing metal-silver shell composite phase-change capsules using stearic acid as a phase-change material comprises the following steps:

[0063] (1) preparation of stearic acid emulsion

[0064] (1-1) Selecting a stearic acid phase change material with a phase transition temperature of 68°C;

[0065] (1-2) choose cetyltrimethylammonium bromide as surfactant;

[0066] (1-3) Add 4g of stearic acid and 0.04g of surfactant to 100ml of deionized water, put it in a 75°C water bath and heat until the stearic acid melts, then stir at 800r / min for 1 hour to form stearic acid Lotion;

[0067] (2) Preparation of phase change emulsion containing silver bromide particles

[0068] (2-1) Pour 10ml of potassium bromide solution with a concentration of 100mMol / L and 10ml of silver nitrate solution with a concentration of 90mMol / L into the stearic acid emulsion prepared in step (1), and continue at 75°C at 700r / min Stirring at a speed of 10min;

[0069] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com