Electric machining device and method for small deep holes

A technology of deep and small holes and electric processing, which is applied in the direction of electric processing equipment, accessory devices, metal processing equipment, etc., can solve problems such as easy vibration, deep and small holes are easy to deflect, and poor rigidity, so as to improve rigidity and promote discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

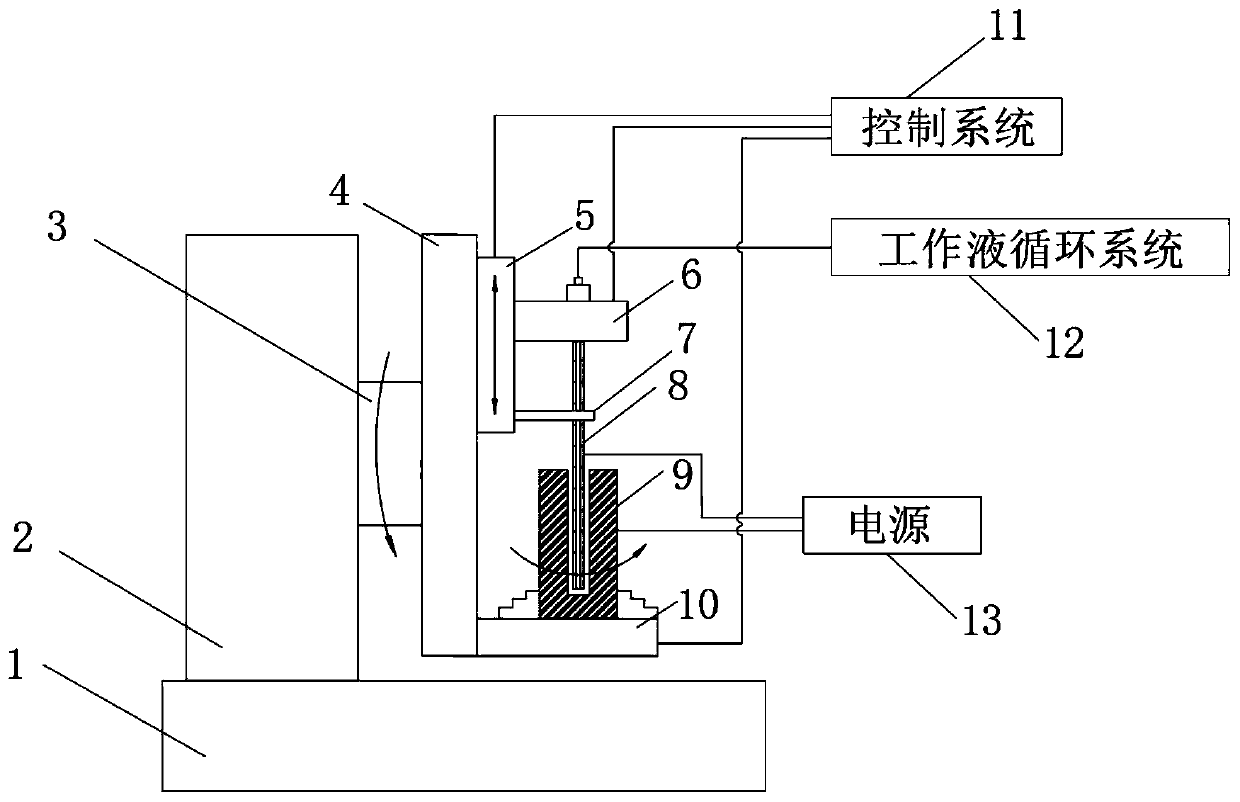

[0016] Such as figure 1 Shown is a schematic diagram of a deep small hole electrical machining device. The tube electrode clamping and driving device (6) is installed on the feeding device (5), and the feeding device (5) is connected to the control system (11). The feeding movement of the tube electrode (8), and the tube electrode (8) is installed on the tube electrode clamping and driving device (6), so that through the feeding device (5) and the tube electrode clamping and driving device (6) The tube electrode (8) can be rotated or fed, or the tube electrode (8) can be rotated and fed simultaneously. The tube electrode clamping and driving device (6) is connected with the working fluid circulation system (12) and the control system (11). The working fluid circulation system (12) provides high-pressure working fluid to ensure that the working fluid and processed products can flow out of the workpiece smoothly ( 9) Processing port. Therefore, the stability during the feeding p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap