Ash synchrotron radiation pressurized sintering experimental device and its application method

A technology of pressurized sintering and experimental device, which is applied in measurement devices, material analysis using wave/particle radiation, instruments, etc. The effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

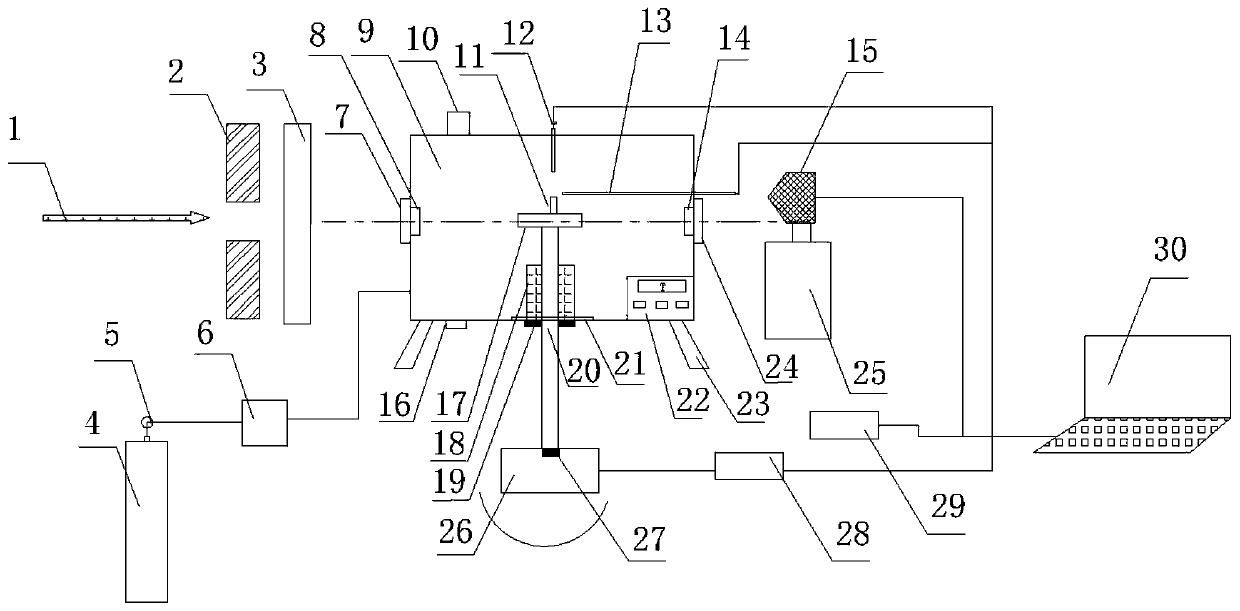

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] like figure 1 As shown, a gray synchrotron radiation pressure sintering experimental device includes a synchrotron radiation light source system, a pressure sintering experimental furnace, a gas supply system, a rotary console, a signal acquisition device, and an image acquisition and processing system. The synchrotron radiation light source system includes a synchrotron radiation light source 1, a collimator 2 and a monochromatic crystal 3; the synchrotron radiation light source is specifically a synchrotron radiation X light source; The collimator is used to turn the outgoing light of the synchrotron radiation source into parallel light, so that the outgoing light can be coupled into the monochromatic crystal with maximum efficiency; the monochromatic crystal is used to turn the parallel light into monochromatic light.

[0025]The pressurized sintering experi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com