Rotational-flow grit chamber with speed regulating and grit discharging functions

A swirling grit chamber and speed regulation technology, which is applied in the direction of settling tanks, sedimentation separation, chemical instruments and methods, etc., can solve the problems of increased production costs, difficulty in sand pumping, high price of governors, etc., to achieve cost savings, The effect of simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

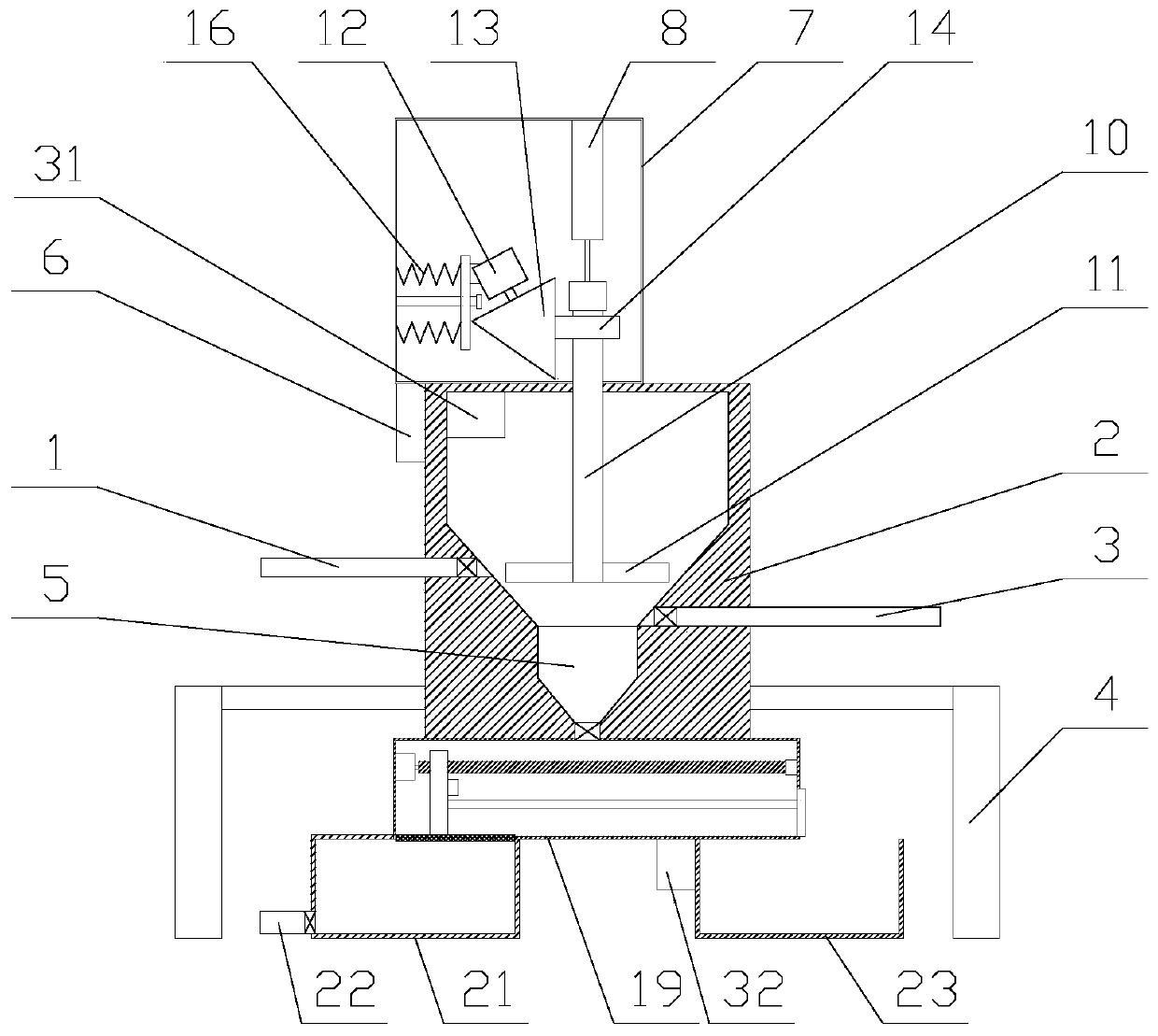

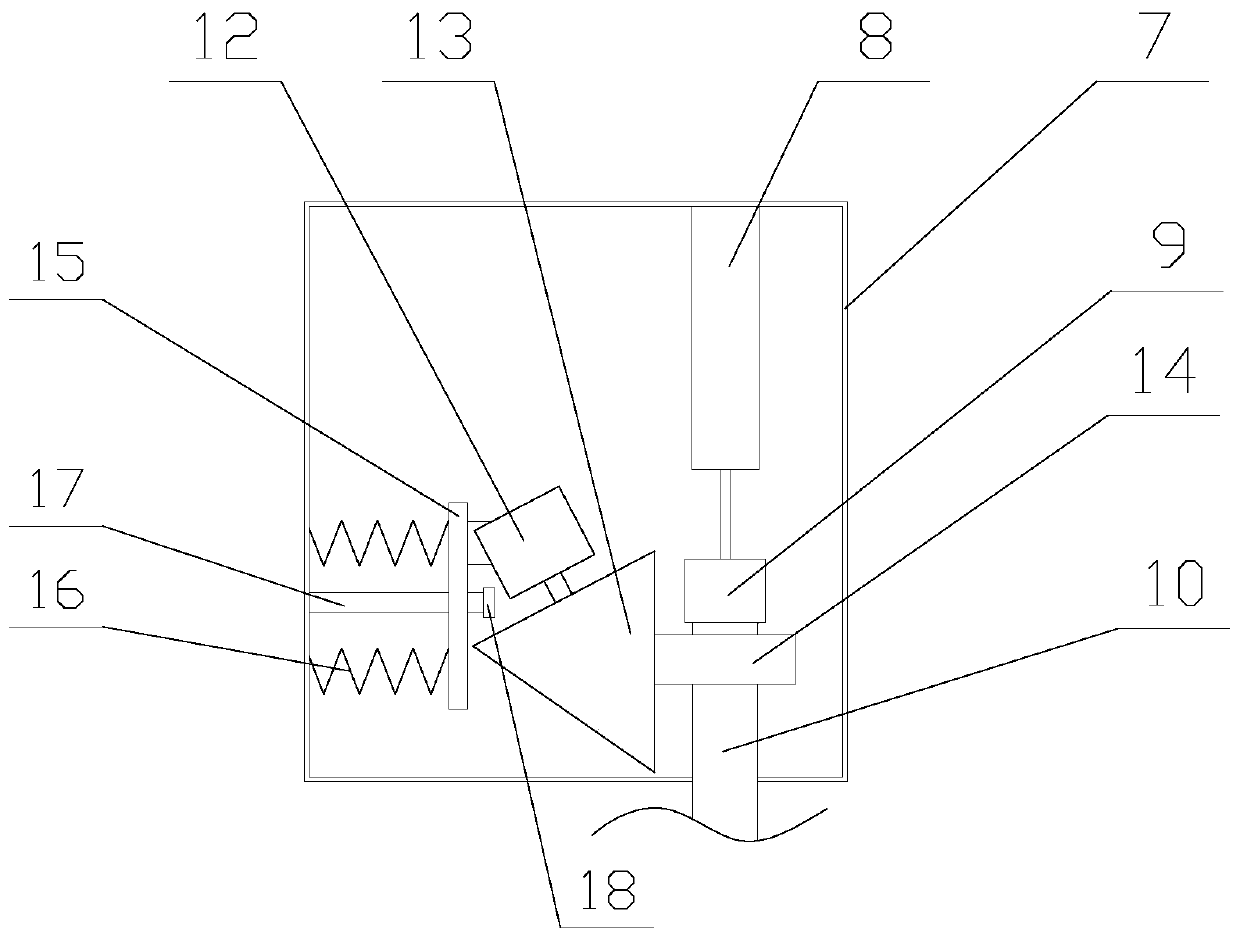

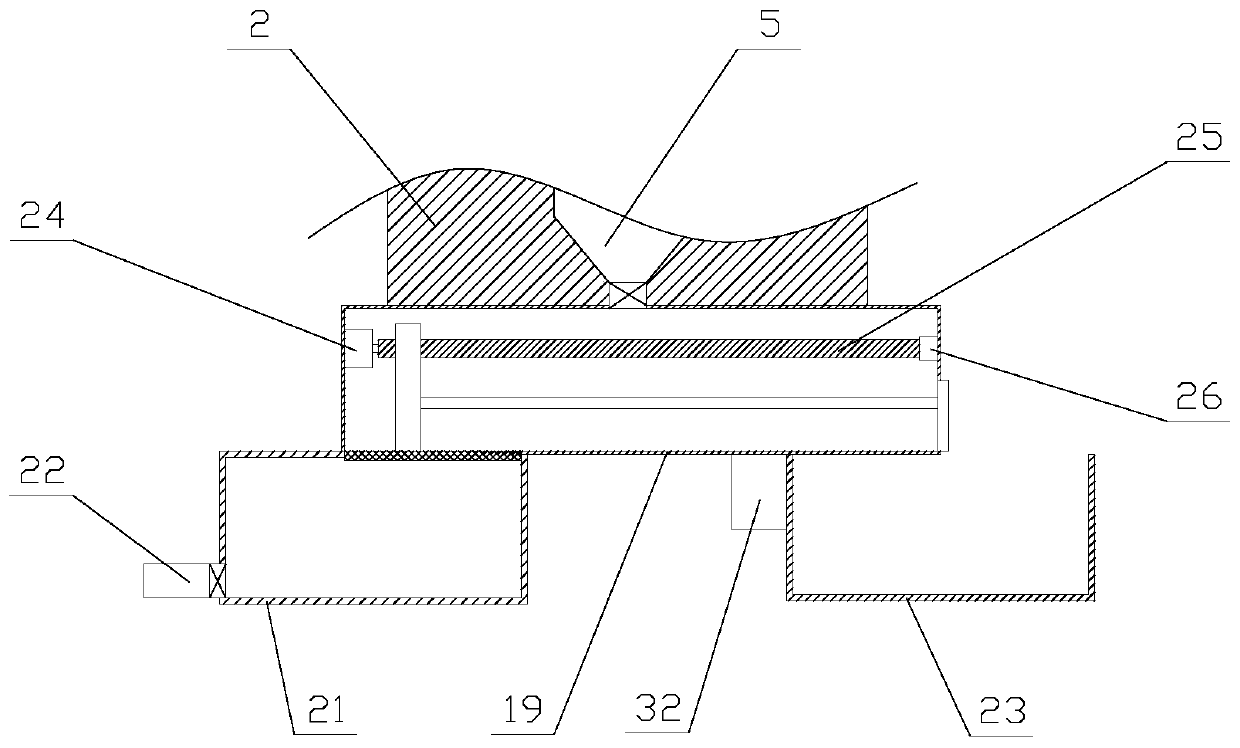

[0025] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0026] Such as figure 1 As shown, a swirling grit chamber with speed regulation and sand discharge function includes water inlet pipe 1, tank body 2, outlet pipe 3 and bracket 4, and the tank body 2 is fixed above the bracket 4, and the inlet The water pipe 1 communicates with the upper part of one side of the pool body 2, and the outlet pipe 3 communicates with the lower part of the other side of the pool body 2. The water inlet pipe 1 is provided with a first valve, and the outlet pipe 3 is provided with The second valve, the bottom of the pool body 2 is provided with a sand bucket 5, the top of the pool body 2 is provided with a speed regulating mechanism,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com