Large-tonnage steel structure honeycomb box beam

A honeycomb girder and steel structure technology, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of heavy weight of concrete box girders, difficulty in pouring or erection, etc., and achieve excellent economic effects, light weight, and improved bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

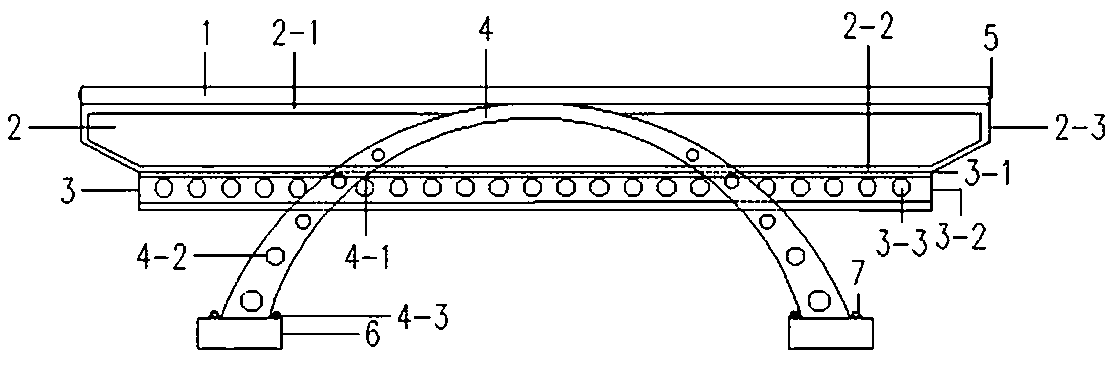

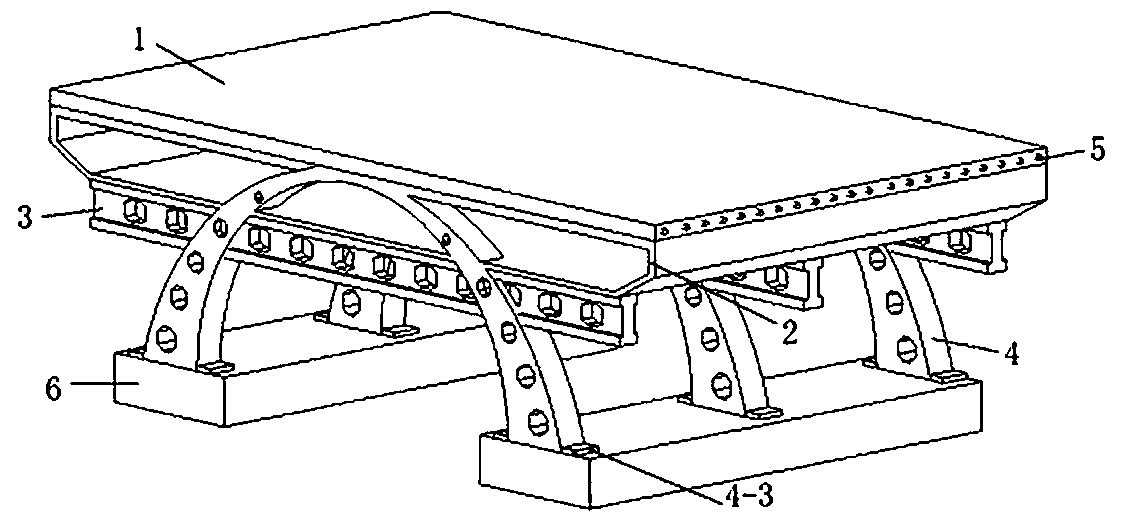

[0017] Such as Figure 1-Figure 2 As shown, a large-tonnage steel structure honeycomb box girder includes prestressed laminated roof 1, box-shaped steel subgrade 2, I-shaped honeycomb beam 3, arched honeycomb beam 4, prestressed tendons 5, caps 6, bolts 7. The prestressed laminated roof 1 is a cuboid, and its interior is connected with prestressed tendons 5. The prestressed tendons 5 are arranged transversely along the width direction of the road. Below the prestressed laminated roof 1 is a box-shaped steel subgrade 2. The laminated top plate 1 is welded above the top plate 2-1 of the box-shaped steel subgrade; the I-shaped honeycomb beam 3 is welded under the base plate 2-2 of the box-shaped steel road, and the lower edge of the web 2-3 is connected with the upper flange of the I-shaped honeycomb beam 3 3-1 welding, the I-shaped honeycomb beam web 3-2 is provided with honeycomb holes 3-3, the I-shaped honeycomb beam 3 is arranged laterally along the width direction of the roa...

Embodiment 2

[0024] Honeycomb box girder, including prestressed laminated roof 1, box-shaped steel subgrade 2, I-shaped honeycomb beam 3, arched honeycomb beam 4, prestressed tendons 5, caps 6, bolts 7, the prestressed laminated roof 1 is a cuboid, and its interior is pierced with prestressed tendons 5, and the prestressed tendons 5 are arranged transversely along the width direction of the road. Below the prestressed laminated roof 1 is a box-shaped steel subgrade 2, and the prestressed laminated roof 1 is welded to the box-shaped steel The top of the subgrade roof 2-1; the bottom of the box-shaped steel road base plate 2-2 is welded with the I-shaped honeycomb beam 3, the lower edge of the web 2-3 is welded with the upper flange 3-1 of the I-shaped honeycomb beam 3, and the I-shaped honeycomb The beam web 3-2 is provided with a honeycomb hole 3-3, and the I-shaped honeycomb beam 3 is arranged transversely along the width direction of the road; The width direction is horizontally arranged...

Embodiment 3

[0031] Honeycomb box girder, including prestressed laminated roof 1, box-shaped steel subgrade 2, I-shaped honeycomb beam 3, arched honeycomb beam 4, prestressed tendons 5, caps 6, bolts 7, the prestressed laminated roof 1 is a cuboid, and its interior is pierced with prestressed tendons 5, and the prestressed tendons 5 are arranged transversely along the width direction of the road. Below the prestressed laminated roof 1 is a box-shaped steel subgrade 2, and the prestressed laminated roof 1 is welded to the box-shaped steel The top of the subgrade roof 2-1; the bottom of the box-shaped steel road base plate 2-2 is welded with the I-shaped honeycomb beam 3, the lower edge of the web 2-3 is welded with the upper flange 3-1 of the I-shaped honeycomb beam 3, and the I-shaped honeycomb The beam web 3-2 is provided with a honeycomb hole 3-3, and the I-shaped honeycomb beam 3 is arranged transversely along the width direction of the road; The width direction is horizontally arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com