Capacitance sensor linearity improvement method

A capacitive sensor and linearity technology, which is applied in the direction of instruments, electric variables, control/regulation systems, etc., can solve the problems of reducing buffer linearity, distortion, signal distortion, etc., and achieve the effect of improving linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

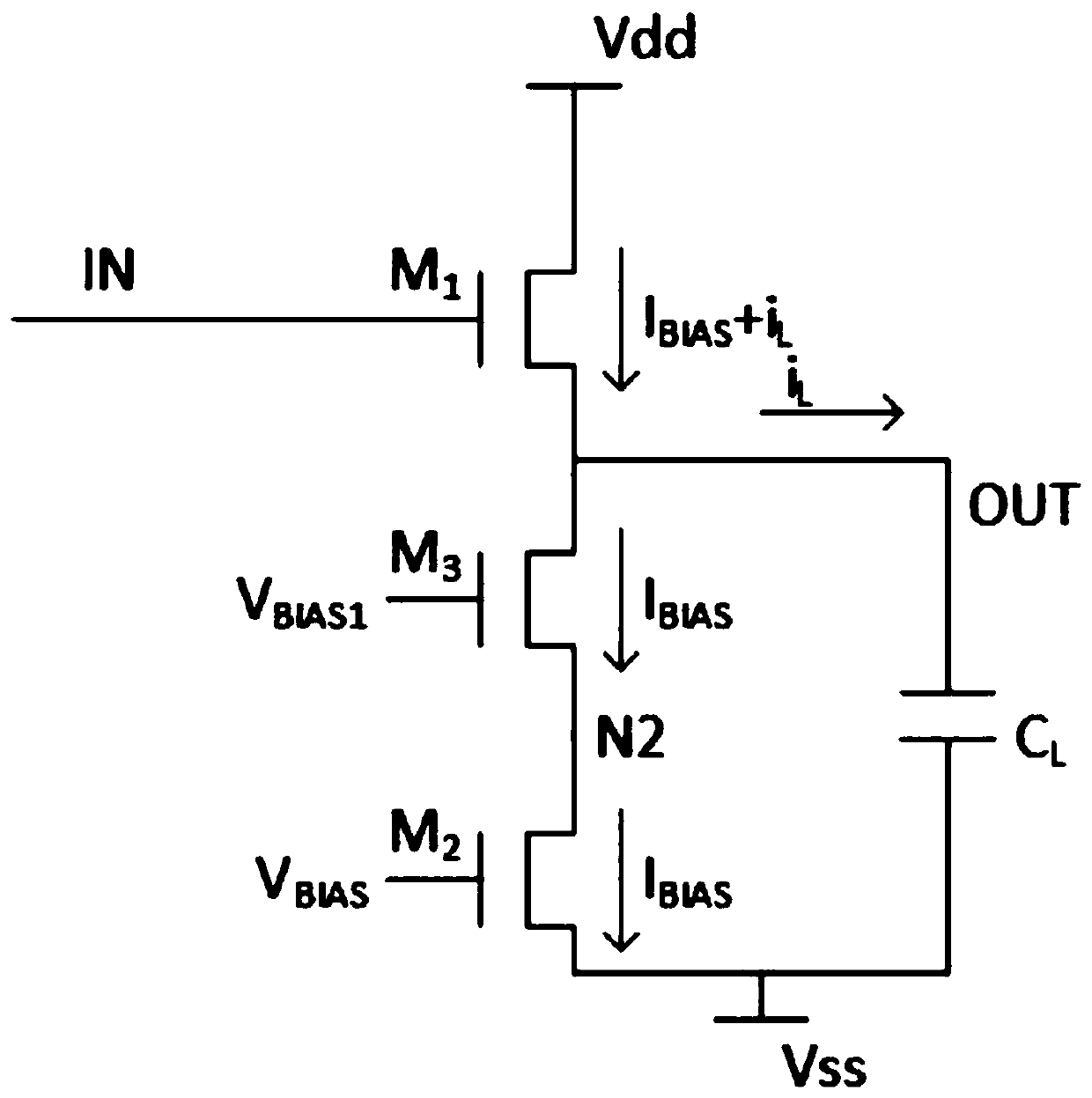

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

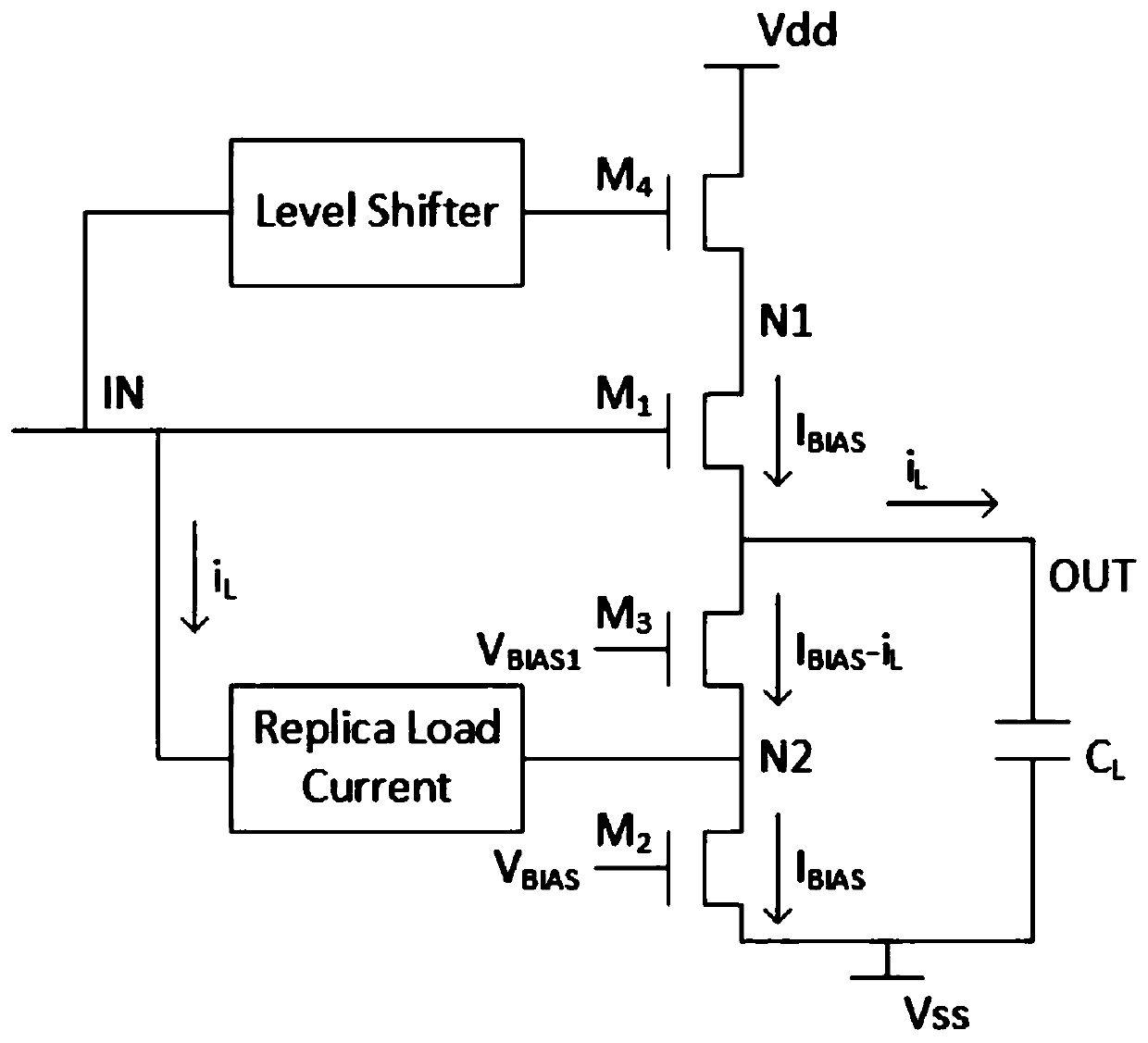

[0016] see figure 2 , a method for improving the linearity of a capacitive sensor related to the present invention, the method steps are: adding voltage buffer four M4, so that voltage buffer four M4, voltage buffer one M1, voltage buffer three M3 and voltage buffer The second M2 is sequentially connected in series between the high level Vdd and the ground terminal Vss, and the voltage buffer four M4 tracks the input signal through a level shifter, so that no matter how the input signal at the input terminal IN changes, the voltage buffer one The VDS (drain-source voltage) of M1 remains unchanged or changes very little; effectively improves the output impedance of the voltage buffer-M1;

[0017] At the same time, a current matching the output load current is introduced at the connection point between the voltage buffer three M3 and the voltage buffer two M2;

[0018] An output capacitor CL is connected between the output terminal and the ground terminal VSS, because the node...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com