Novel separate rail tray cable bridge frame

A cable tray and tray-type technology, applied in the direction of electrical components, etc., can solve the problems of no separation partition, cable burnt, cable tray without flame-retardant partition, etc., to ensure the safety of life and property, avoid mutual interference, and avoid the spread of fire Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

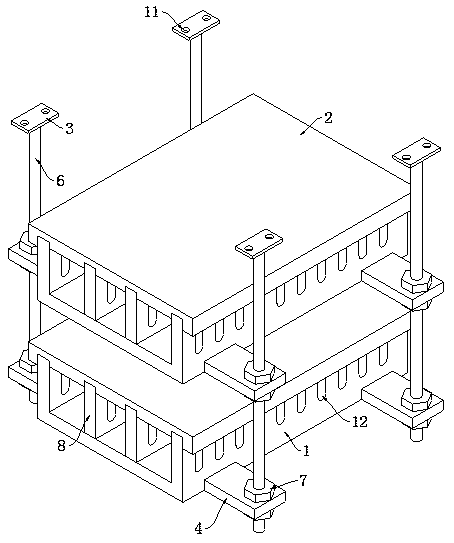

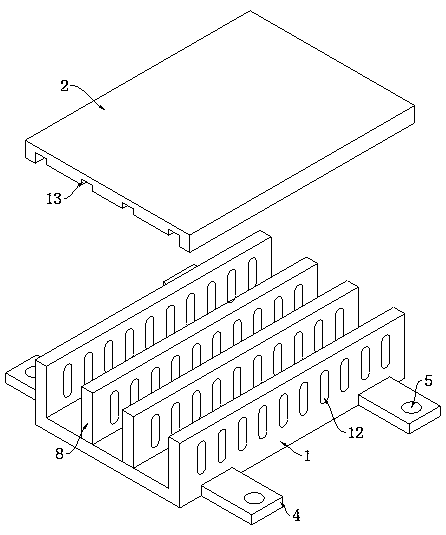

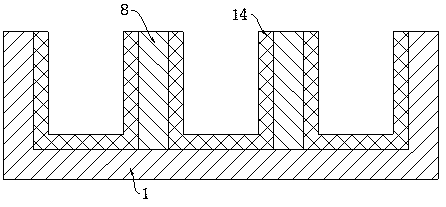

[0021] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention is a new type of split-rail tray type cable bridge, including two bridge bodies 1, two bridge cover plates 2 and several first fixing plates 3, and the bridge cover plates 2 are snapped and connected to the bridge body 1. The top, the bottom of both sides of the bridge body 1 are fixedly provided with several second fixed plates 4, and the several second fixed plates 4 are equidistantly distributed on both sides of the bridge body 1, and the tops of several first fixed plates 3 are A first through hole 5 is provided, and threaded columns 6 are fixed in the middle of the bottom ends of several first fixing plates 3, and several threaded columns 6 are plugged into corresponding first through holes 5 respectively, and several second fixing plates The top and bottom ends of 4 are provided with fastening nuts 7, and several fastening nuts 7 are threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com