Roller bearing with microstructures on surfaces of roller ways and lubricating method of roller bearing

A roller bearing and micro-texture technology, which is applied in the direction of shafts and bearings, bearing components, mechanical equipment, etc., can solve the problem that the surface texture structure is not suitable for roller bearings, achieve improved lubrication effect, improve physical properties, improve Effect of wear resistance and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

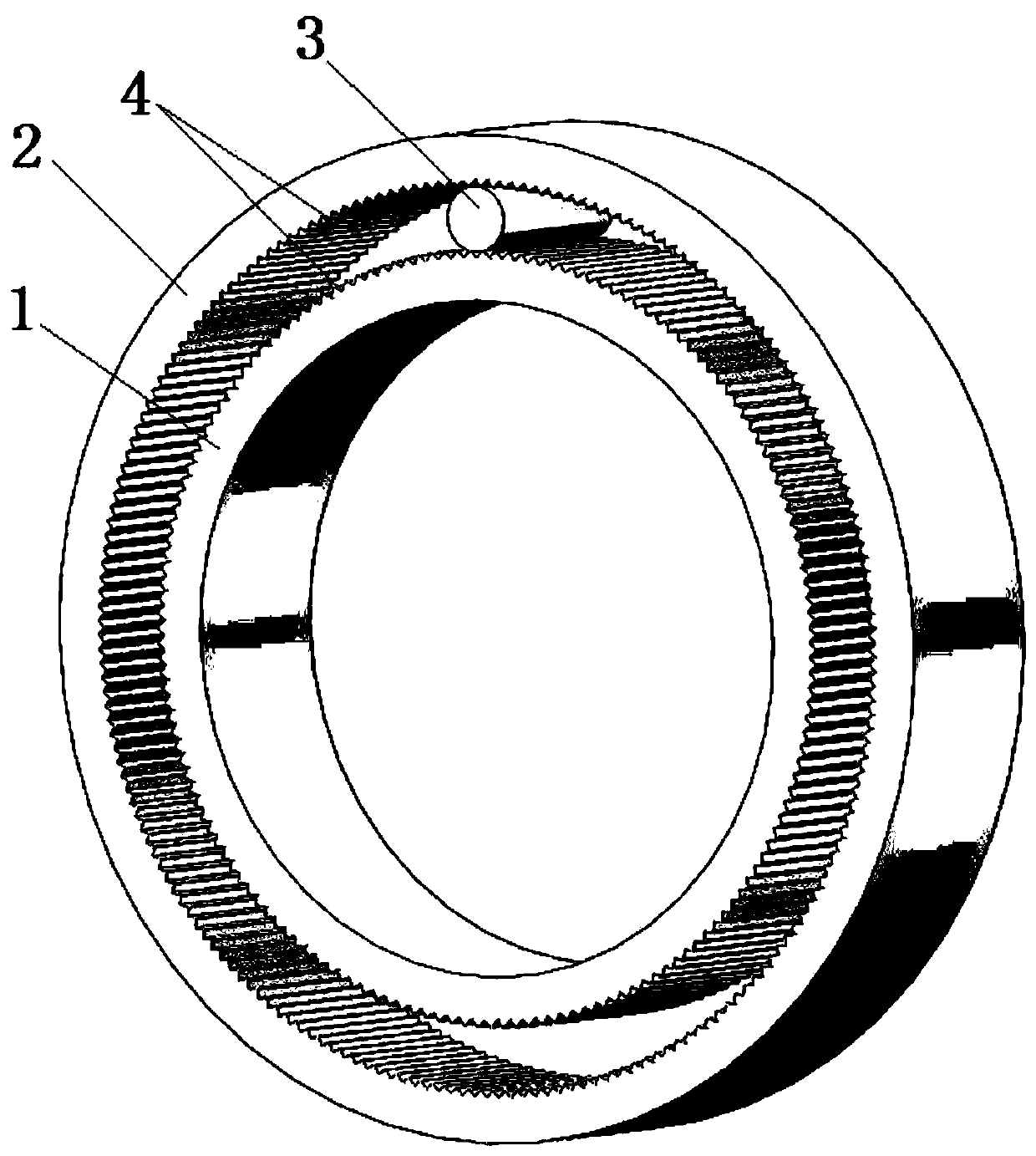

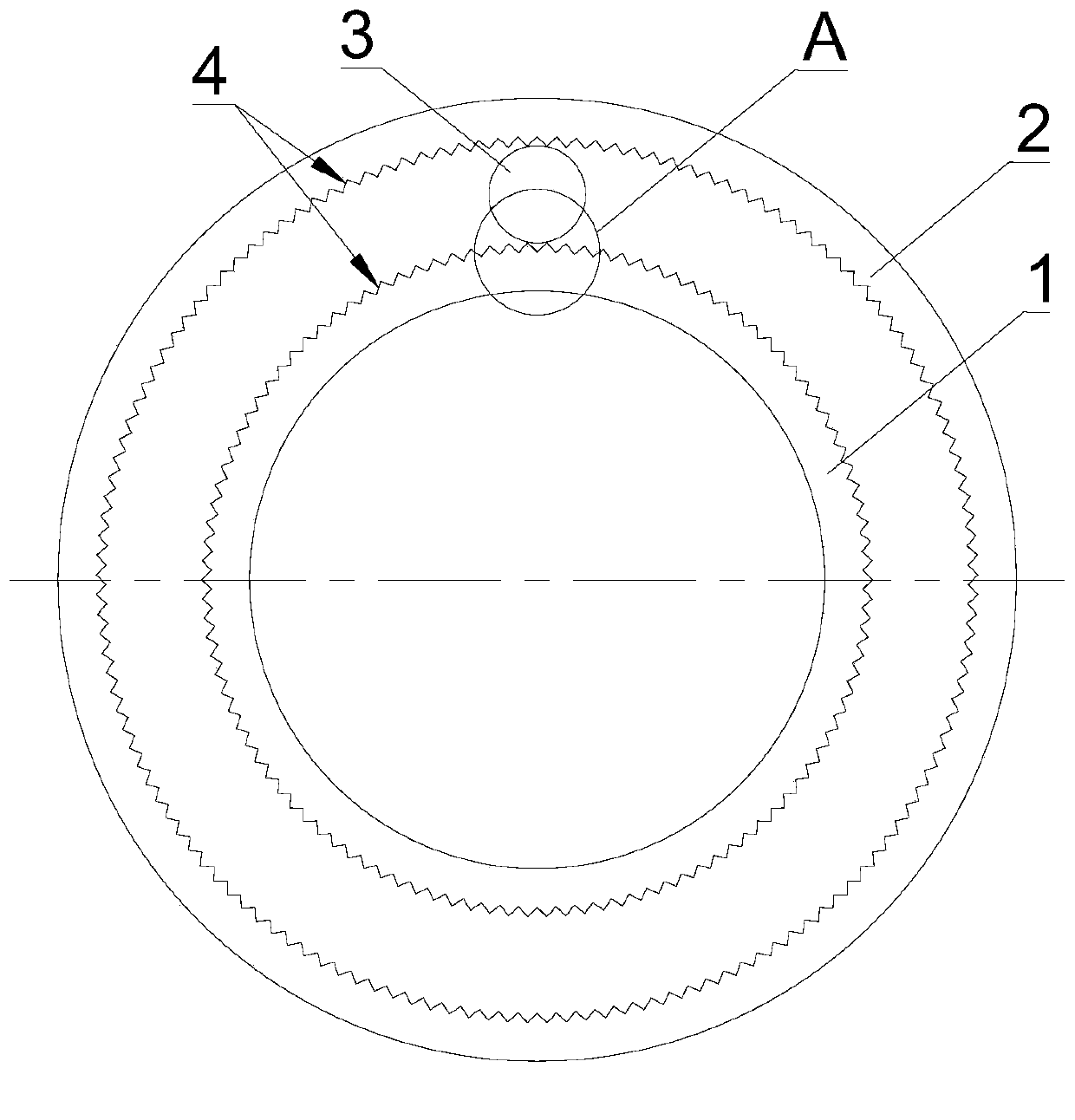

[0030] See Figure 1-3 , The roller bearing with a micro-textured raceway surface in this embodiment includes a bearing inner ring 1, a bearing outer ring 2, and a rolling element 3 arranged between the bearing inner ring 1 and the bearing outer ring 2; wherein, The raceway surface of the bearing inner ring 1 and the raceway surface of the bearing outer ring 2 are both provided with a reinforced abrasive layer, and the surface of the reinforced abrasive layer is provided with a micro-textured structure; the micro-textured structure consists of multiple edges The vertical strip-shaped grooves 4 uniformly arranged in the circumferential direction are formed, and the extending direction of the vertical strip-shaped grooves 4 is parallel to the axial direction of the bearing.

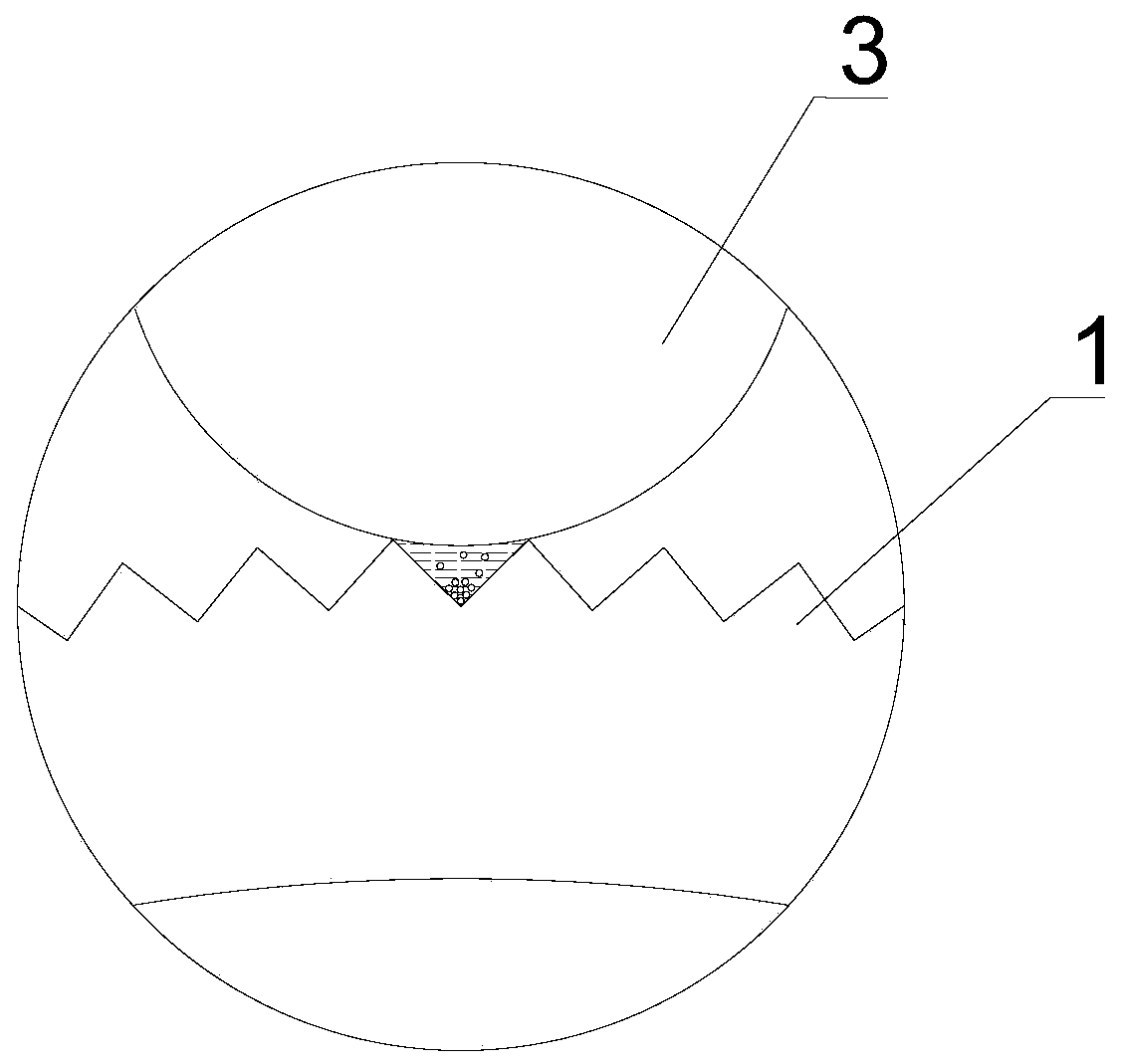

[0031] See Figure 1-3 The cross section of the vertical strip-shaped groove 4 is "V" shaped.

[0032] See Figure 4-6 , F 1 , F 2 Is the contact stress of the "V"-shaped groove, and the magnit...

Example Embodiment

[0054] Example 2

[0055] In a preferred solution of the present invention, the cross section of the vertical strip-shaped groove 4 is an arc, and the arc is an inferior arc.

[0056] Further, the cross section of the vertical strip-shaped groove 4 may be a circular arc shape, an elliptical arc shape, a parabolic shape or other high-order curved arc shapes.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap