Direct drive motor for clothing treatment device and clothing treatment device

A technology of clothing treatment equipment and a direct drive motor, applied in the field of clothing treatment, can solve the problems affecting the performance and service life of the direct drive motor, the temperature of the direct drive motor, etc., so as to improve the heat dissipation effect, avoid excessive temperature, and improve the support strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

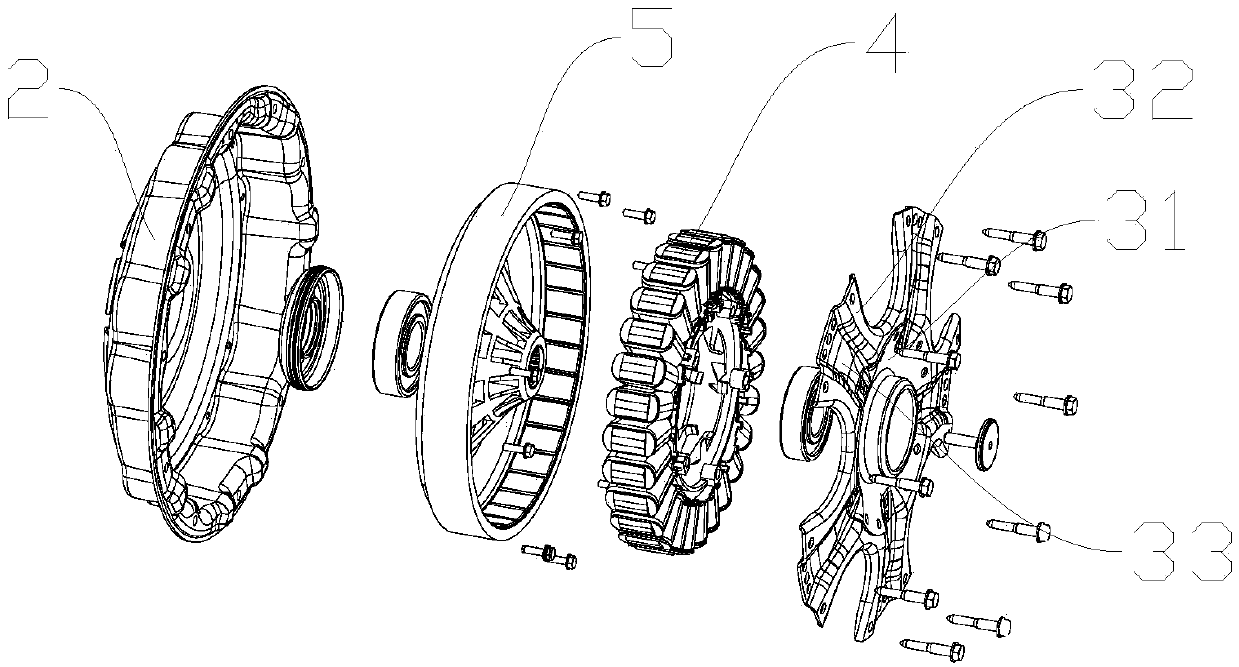

[0024] First of all, those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention and are not intended to limit the protection scope of the present invention. For example, although the following embodiments are explained in conjunction with a drum washing machine, this is not limitative. The technical solution of the present invention is also applicable to other laundry treatment equipment, such as clothes dryers, dry cleaning machines, and washing-drying machines. This kind of application object change does not deviate from the principle and scope of the present invention.

[0025] It should be noted that in the description of the present invention, the terms "center", "front", "rear", "inner", "outer" and other terms indicating the direction or positional relationship are based on the direction or position shown in the drawings. The positional relationship is only for ease of description, and does n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap