Power conversion device

A technology of power conversion devices and capacitors, which is applied in the direction of output power conversion devices, electrical components, and structural parts of conversion equipment, etc., which can solve the problems of increased size, inability to improve vehicle space efficiency and layout, and improve wiring efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Hereinafter, an embodiment of the power conversion device of the present invention will be described with reference to the drawings.

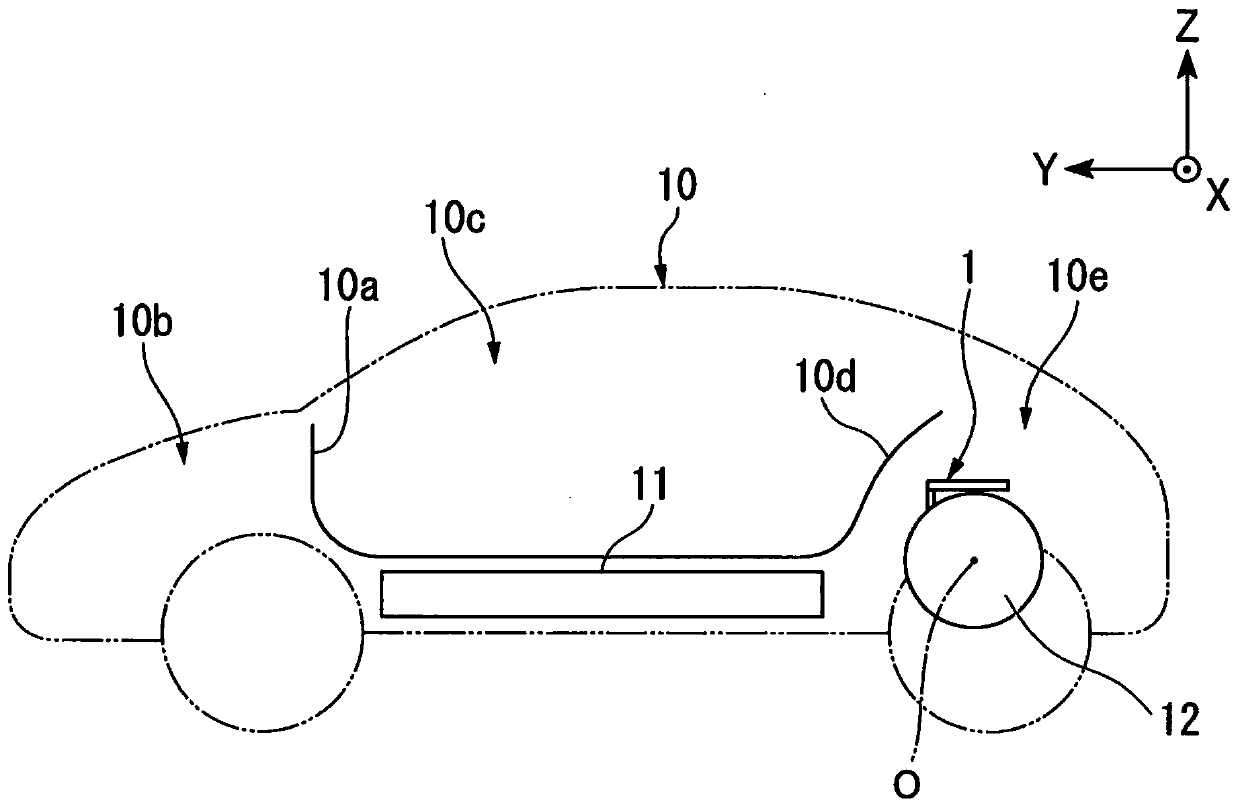

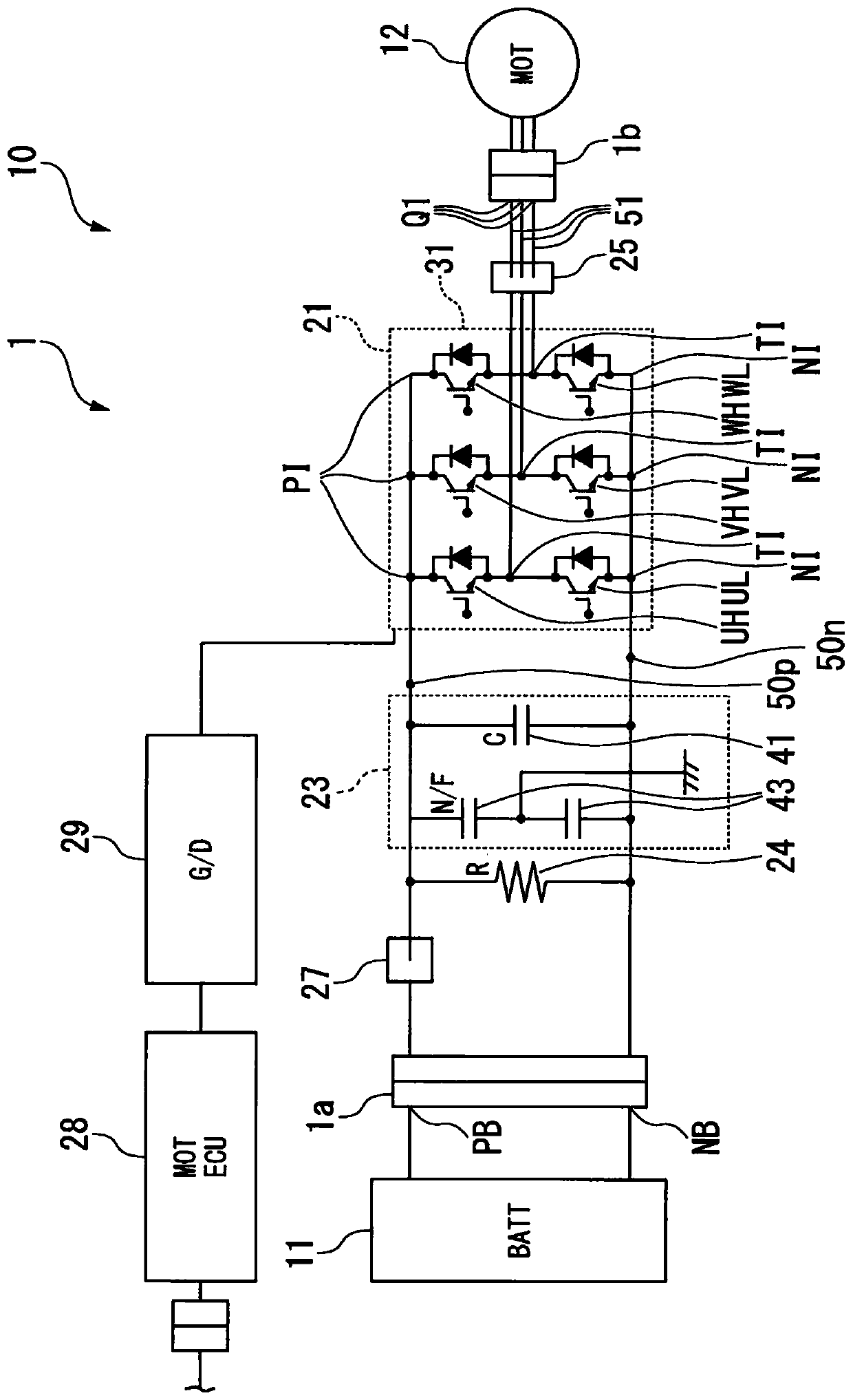

[0027] The power conversion device of this embodiment controls the power transfer between the motor and the battery. For example, the power conversion device is mounted on an electric vehicle or the like. Electric vehicles include electric vehicles, hybrid vehicles, and fuel cell vehicles. Electric vehicles are driven by batteries as a power source. Hybrid vehicles use batteries and internal combustion engines as power sources for driving. Fuel cell vehicles use fuel cells as a power source for driving.

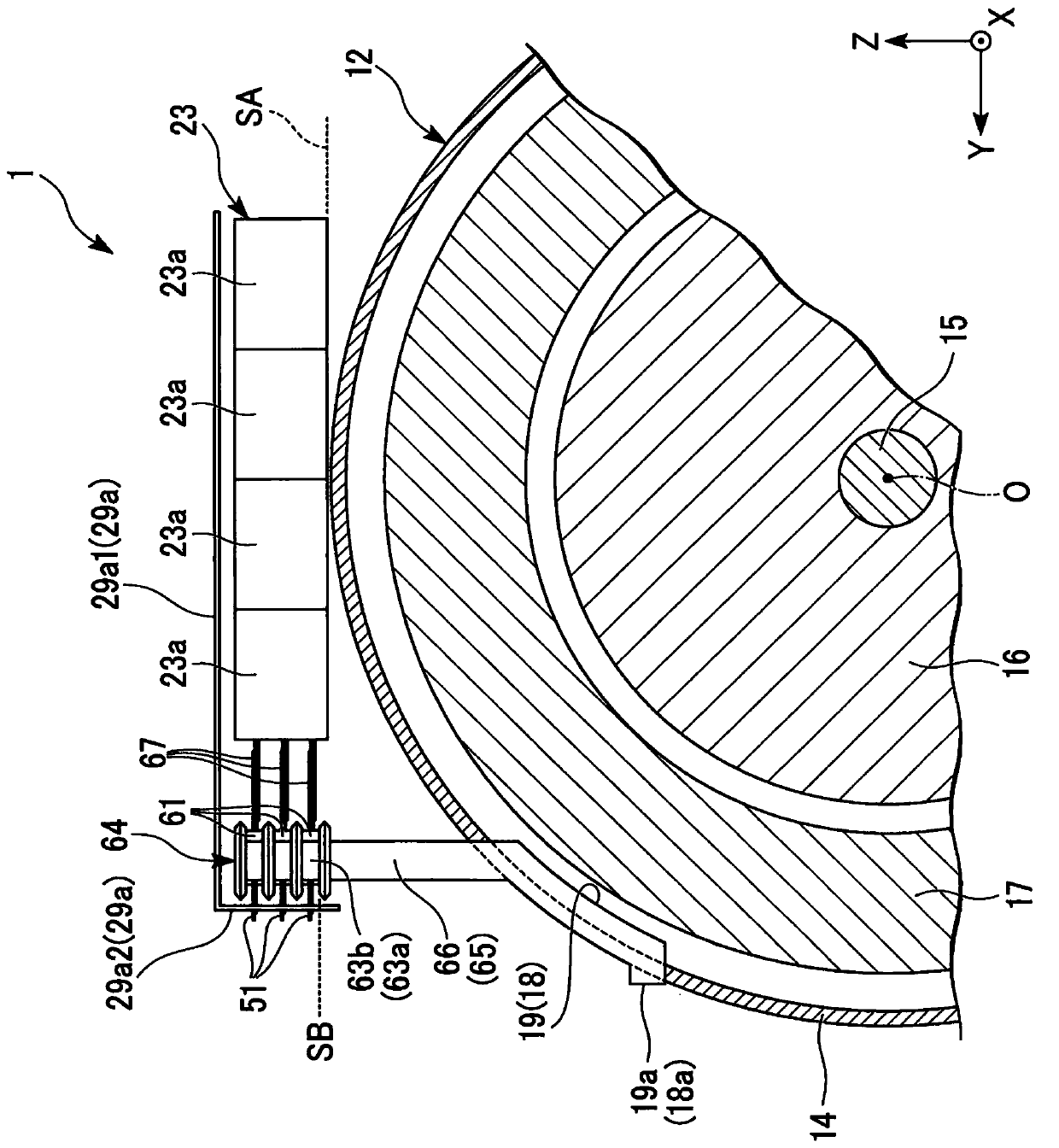

[0028] figure 1 It is a diagram schematically showing the structure of the power conversion device 1 according to the embodiment of the present invention, and is a diagram showing a part of the electric motor 12 when viewed from the axial direction of the electric motor 12 and a part of the power conversion device 1 is omitted. figure 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap