A kind of environmental protection and energy-saving powder coating and its preparation method and application

A powder coating, environmental protection and energy-saving technology, applied in powder coatings, polyester coatings, coatings and other directions, can solve the problems of large energy consumption, formulation cost, transportation and storage can not be used on a large scale, not in line with energy conservation and emission reduction, etc., to save energy. , The effect of formula and process cost reduction and large cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

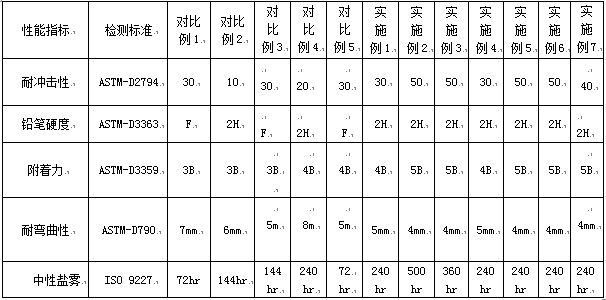

Examples

Embodiment 1-6 and comparative example 1-4

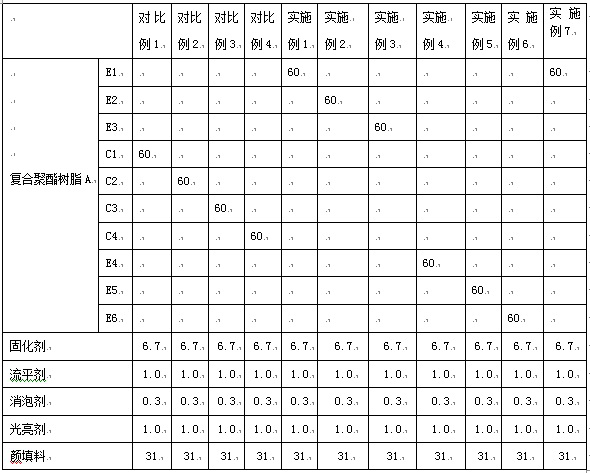

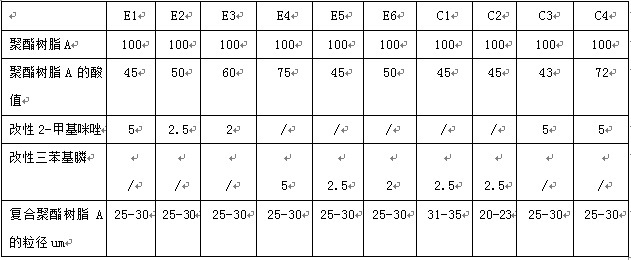

[0050] a. Mix the polyester resin A and the modified catalyst uniformly according to the ratio in Table 1, and then melt and extrude them through a twin-screw extruder. The melt-extrusion temperature of the twin-screw extruder is 150 ° C, and the tableting is cooled to normal temperature, and crushed to obtain Composite polyester resin A with a particle size of 25um-30um;

[0051] b. Put the composite polyester resin A, curing agent, leveling agent, defoamer, brightener, pigment and filler in the pre-mixing cylinder according to the proportions in Table 2, and then melt and extrude through the twin-screw extruder after mixing evenly. The melt extrusion temperature of the twin-screw extruder is 100°C, the tableting is cooled to room temperature, and finally crushed and classified by a high-speed pulverizer to make powder with a particle size of 30um-35um.

Embodiment 7

[0053] Crush to obtain composite polyester resin A with a particle size of 60um-70um, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com