Sewage treatment device for sheet metal production

A technology of sewage treatment device and sheet metal, which is applied in water/sewage treatment, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc. It can solve the problem that sewage is difficult to meet discharge standards, water resources cannot be recycled, and the filtering effect is not very good. and other problems, to achieve the effect of promoting recycling, sufficient electrolysis, and improving filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

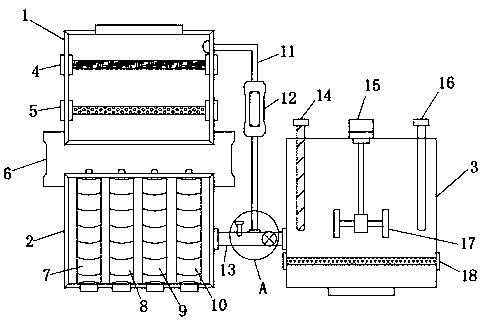

[0021] Such as figure 1 As shown, a sewage treatment device for sheet metal production includes a primary filter box 1, a secondary filter box 2 and a tertiary electrolytic purification box 3, the primary filter box 1 is located on the upper part of the secondary filter box 2, and the tertiary electrolytic purification box The box 3 is located on the side of the secondary filter box 2, the bottom of the primary filter box 1 is provided with an activated carbon filter 6, the primary filter box 1 communicates with the secondary filter box 2 through the activated carbon filter 6, and the internal card of the primary filter box 1 The oil filter 4 and the metal rubber filter 5 are connected, the oil filter 4 is located above the metal rubber filter 5, and the secondary filter box 2 is connected with an ion exchange resin filter element 7, a glass fiber filter element 8, a ceramic filter element 9 and a composite Filter element 10, ion exchange resin filter element 7 is provided wit...

Embodiment 2

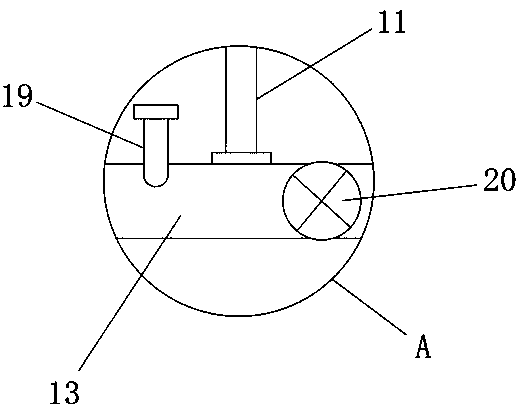

[0024] Such as Figure 1-2 As shown, the external side of the secondary filter box 2 is inlaid with a connecting pipe 13, the secondary filter box 2 communicates with the tertiary electrolytic purification box 3 through the connecting pipe 13, and the connecting pipe 13 is equipped with a sewage detection PH sensor 19 and a pipeline 11 and solenoid valve 20, the sewage detection PH sensor 19 is located on one side of the pipeline 11, and the solenoid valve 20 is located on the other side of the pipeline 11, the sewage detection PH sensor 19 is electrically connected to the solenoid valve 20, and the circulation pump 12 is installed on the pipeline 11. The pipeline 13 is connected to the primary filter box 1 through the pipeline 11, the anode rod 14 is installed on one side of the three-stage electrolytic purification box 3, and the cathode rod 16 is installed on the other side of the three-stage electrolytic purification box 3. 3 is provided with a stirring paddle 17 inside, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com