A construction method for pre-reinforcement of excavated caverns by using deep soft rock to form cavities

A construction method and pre-reinforcement technology, which is applied in earth drilling, underground chambers, shaft equipment, etc., can solve the problems of not making good use of soft rock in the mountain, achieve obvious support effects, realize automatic control, and take a long time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

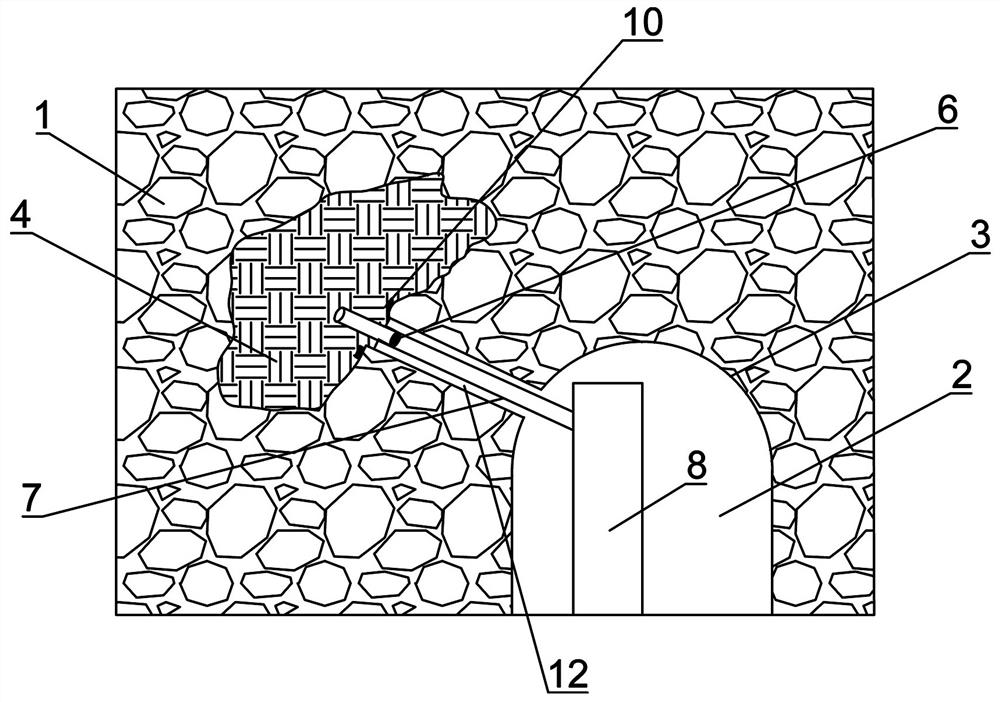

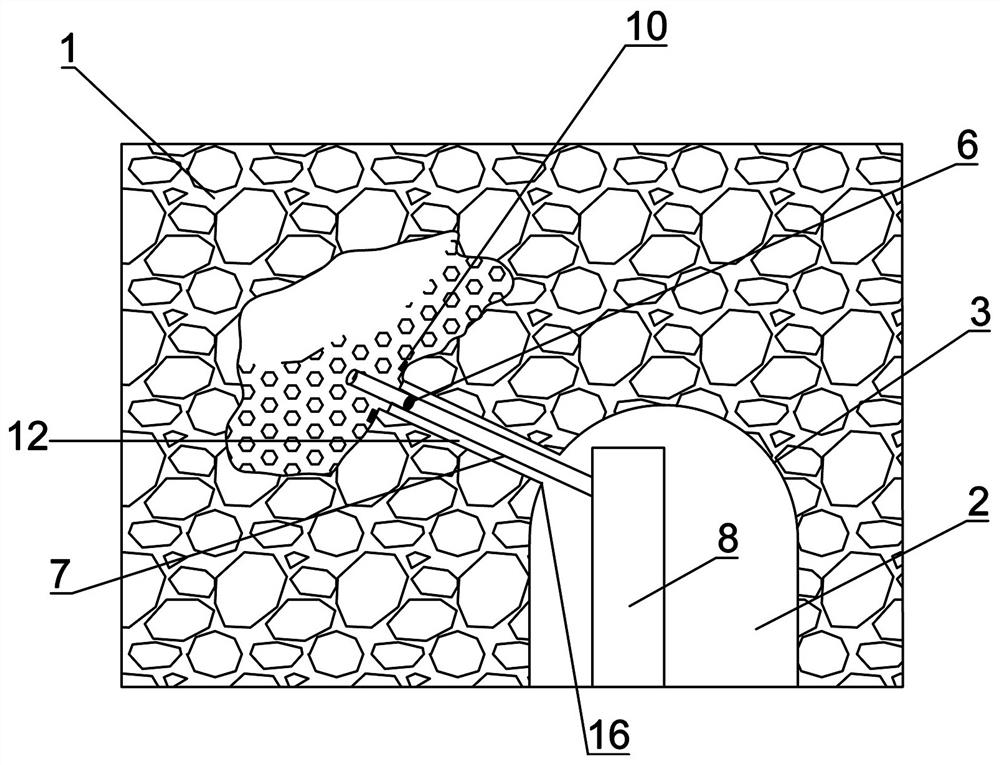

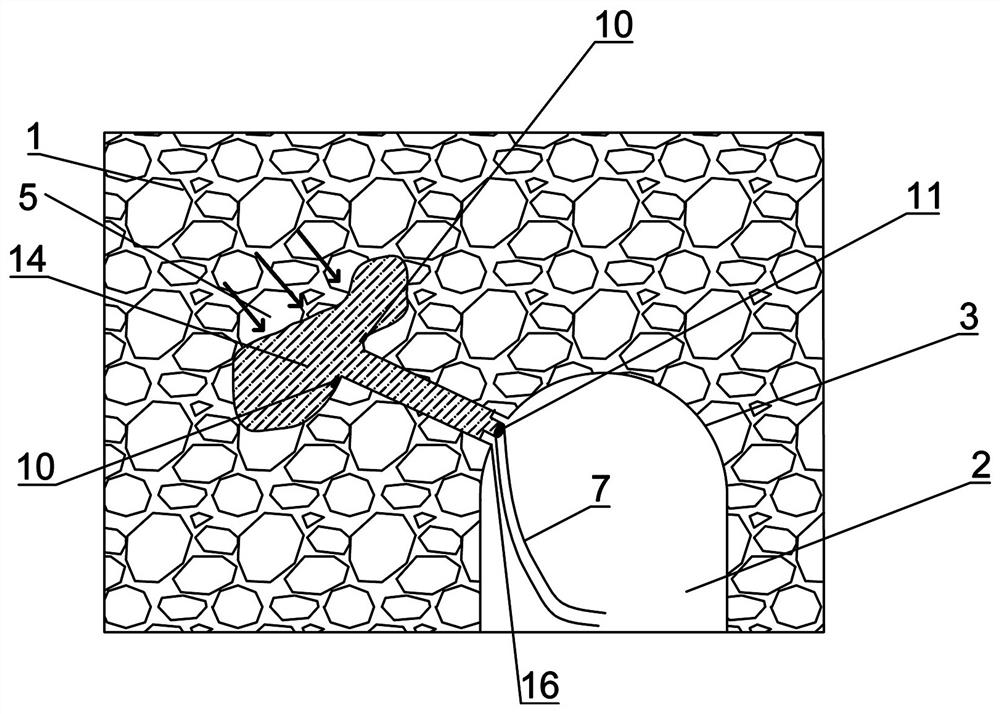

[0038] Such as Figure 1-Figure 4 As shown, a construction method for excavating cavern pre-reinforcement by using deep soft rock to form a cavity, the method includes the following steps:

[0039] Step 1: Utilize the sonic detector to detect the distribution of rock formations around the tunnel 2, analyze the rock formations of the tunnel 2, and find out the distribution of the soft rock formation 4 in the surrounding rock 1 of the rock formation;

[0040] Step 2: Excavate the tunnel 2, drill holes along the wall of the tunnel 2, and complete the initial lining 3;

[0041] Step 3: Under the condition of ensuring the stability of the tunnel, use the drilling equipment to avoid the anchor rod to drill the part of the top of the tunnel 2 under greater stress to form a hole 12 to reach the middle part of the soft rock layer 4 and clean up the gravel in the hole 12;

[0042] Step 4: Arranging a pressure monitor 10 around the drilled hole 12 that can monitor the stress of the surr...

Embodiment 2

[0060] The structure of the automatic pressure relief valve 11 used in the above-mentioned embodiment is as follows:

[0061] Such as Figure 5 As shown, an automatic pressure relief valve 11 includes a valve body 17 with an open upper end surface and a lower end surface, a valve ball 18 is installed at the opening of the lower end surface inside the valve body 17, and a threshold value is installed at the opening of the upper end surface inside the valve body 17. Adjusting device, the valve ball 18 is connected with the threshold adjusting device by a pressure spring 19; the threshold adjusting device includes an adjusting screw 8 threadedly connected to the inner wall of the valve body 17, and the adjusting screw 8 is provided with a pressure scale 27 with a rotating handle 25; The valve body 17 is provided with a pressure relief inlet hole 22 on the side wall at one end of the valve ball 18, and a pressure relief outlet hole 23 is provided on the middle side wall of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com