Circulating liquid injection device and process for lithium battery

A liquid injection device, lithium battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as explosion-proof valve bursting, low liquid injection efficiency, deformation, etc., to avoid vacuuming, achieve full infiltration, improve The effect of injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

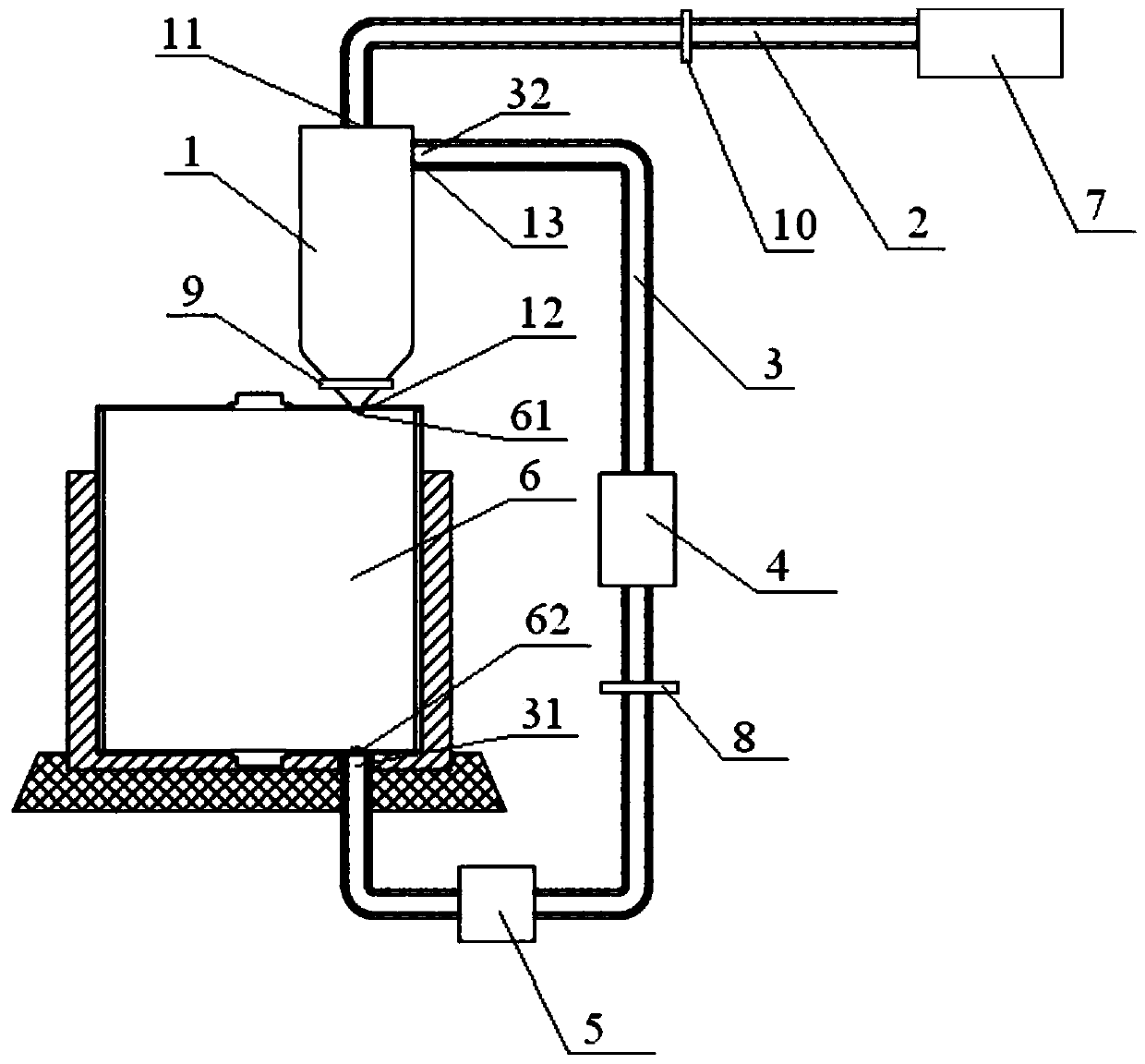

[0030] In order to better understand the present invention, the invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0031] In order to solve the problem of low liquid injection efficiency in the existing lithium ion battery liquid injection process, the present invention provides a lithium battery circulation liquid injection device and a liquid injection process, through which the electrolyte circulates in the lithium battery to realize the electrolyte and the pole pieces Fully infiltrating, avoiding complex vacuuming and vacuum breaking procedures, and improving the efficiency of lithium battery injection. The preferred modes of the lithium battery circulation injection device and the injection process of the present invention will be described in detail below through specific examples.

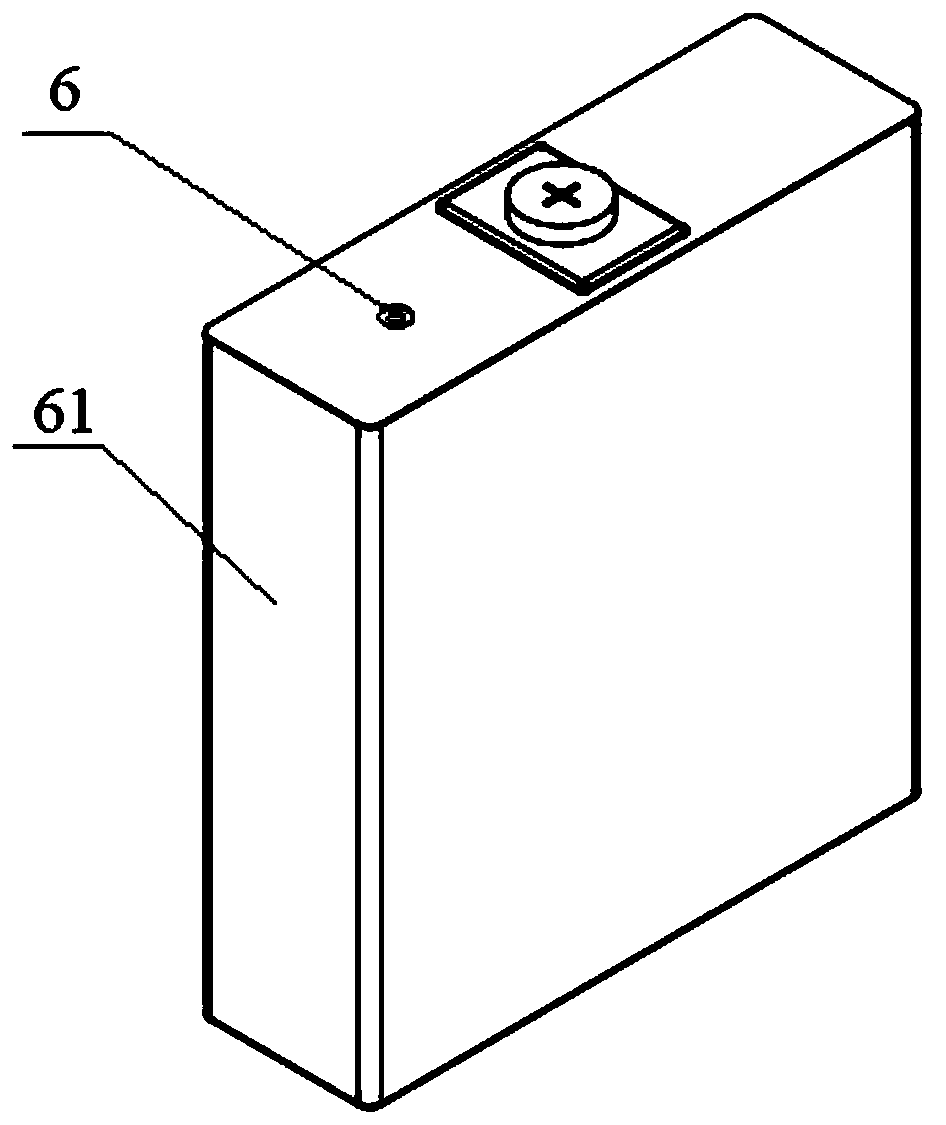

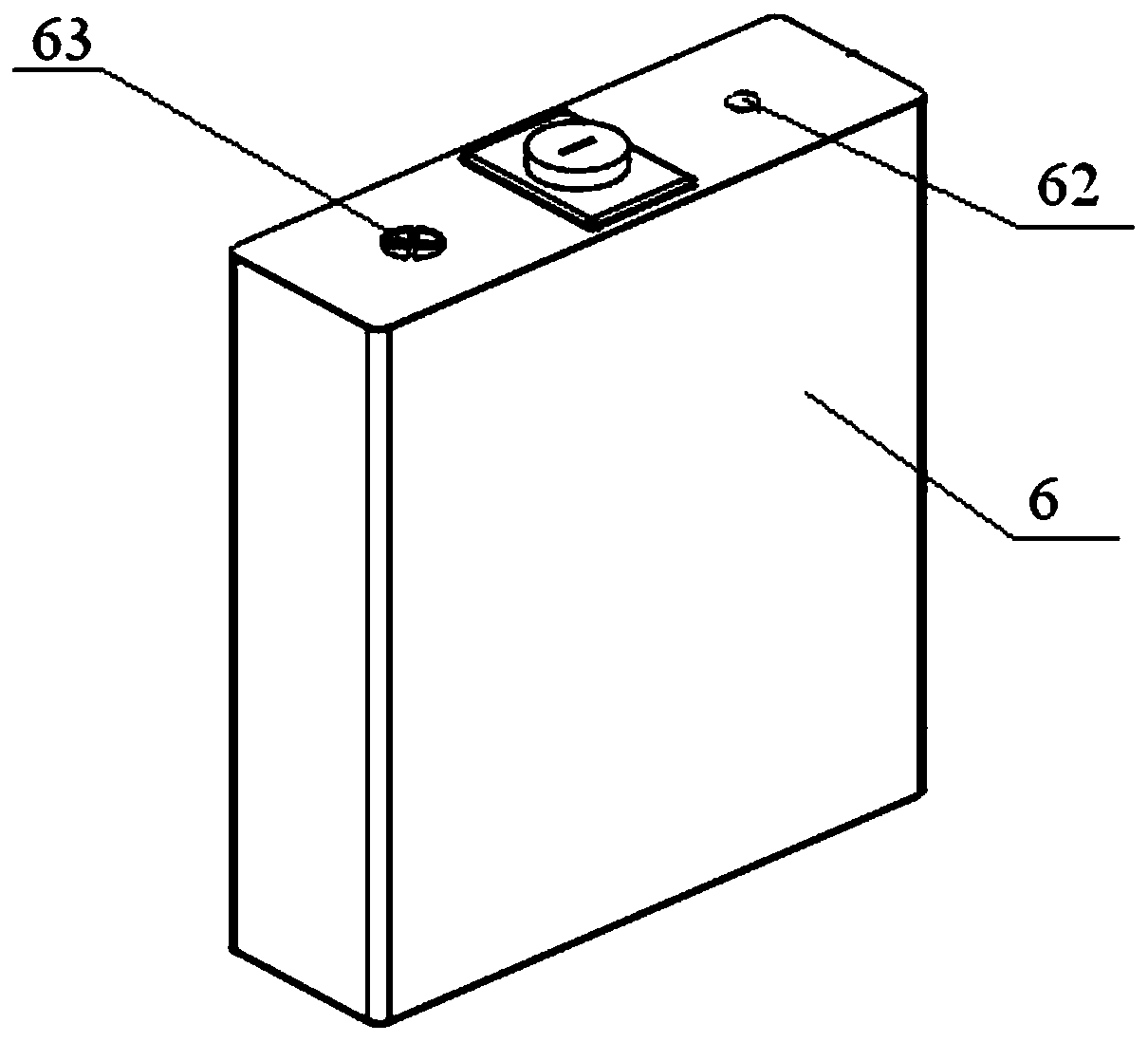

[0032] See 2 and image 3 As shown, the present invention is improved on the basis of traditional lithium ion batteries, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com