Production method of low-compression-ratio super-strength steel Q960E super-thick plate

A technology of ultra-high-strength steel and production methods, applied in the field of steelmaking, can solve the problems of low steel ingot rolling yield, high alloy composition content, high production cost, etc., and achieve the effects of short production cycle, good performance uniformity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

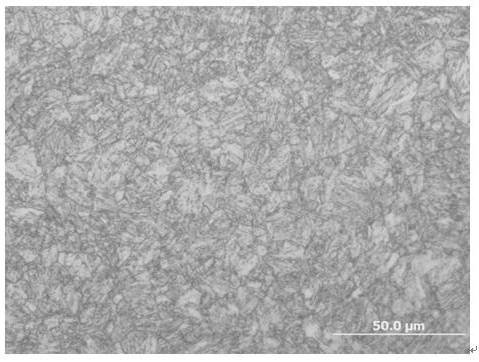

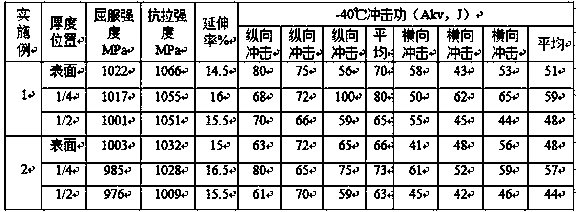

[0021] Example 1: Production of 90mmQ960E steel plate

[0022] The composition mass percentage of steel is C=0.16, Si=0.22, Mn=1.22, P=0.011, S=0.0021, Nb=0.029, V=0.050, Ti=0.015, Als=0.030, Cr=0.62, Mo=0.51, Ni=1.15, B=0.0015, CEV=0.67, the balance is Fe and other trace elements.

[0023] The production process steps include:

[0024] (1) The converter and refining are controlled in accordance with clean steel production. The hydrogen content of molten steel is 1.3ppm, the total oxygen content is 8ppm, and the nitrogen content is 35ppm. Continuous casting overheating degree 13~15℃, cross section 300mm×2270mm, electromagnetic stirring current 265A, frequency 6HZ, dynamic soft reduction 6.3mm.

[0025] (2) Rolling process: After the slab is heated by the heating furnace, the tapping temperature is 1240°C, the soaking time is 41 minutes, and the three-pass reduction after rough rolling and widening is 32mm, 37mm and 38mm, and the reduction rate is 14 %, 19% and 24%. The thickness of...

Example Embodiment

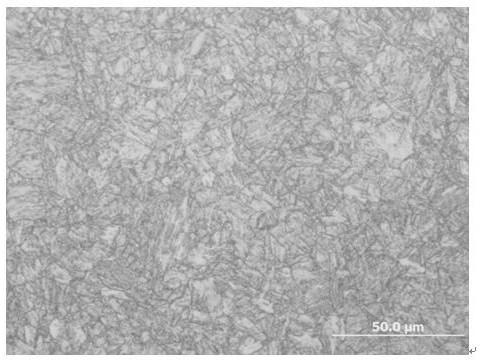

[0028] Example 2: Production of 120mmQ960E steel plate

[0029] The composition mass percentage of steel is: C=0.17, Si=0.22, Mn=1.25, P=0.010, S=0.0018, Nb=0.026, V=0.052, Ti=0.018, Als=0.025, Cr=0.64, Mo=0.53 , Ni=1.17, B=0.0014, CEV=0.68, the balance is Fe and other trace elements. The production process steps include:

[0030] (1) The converter and refining are controlled in accordance with clean steel production. The hydrogen content in molten steel is 1.0ppm, the total oxygen content is 9ppm, and the nitrogen content is 30ppm. Continuous casting overheating 11~14℃, cross section 300mm×2270mm, electromagnetic stirring current 267A, frequency 5.5HZ, dynamic soft reduction 6.5mm.

[0031] (2) Rolling process: After the slab is heated by the heating furnace, the tapping temperature is 1235℃, the soaking time is 45 minutes, and the three passes after the rough rolling and widening, the reductions are 34mm, 43mm and 45mm, and the reduction rates are 13 respectively. %, 18% and 23%...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap